Общий каталог SGS 2018 - страница 254

Навигация

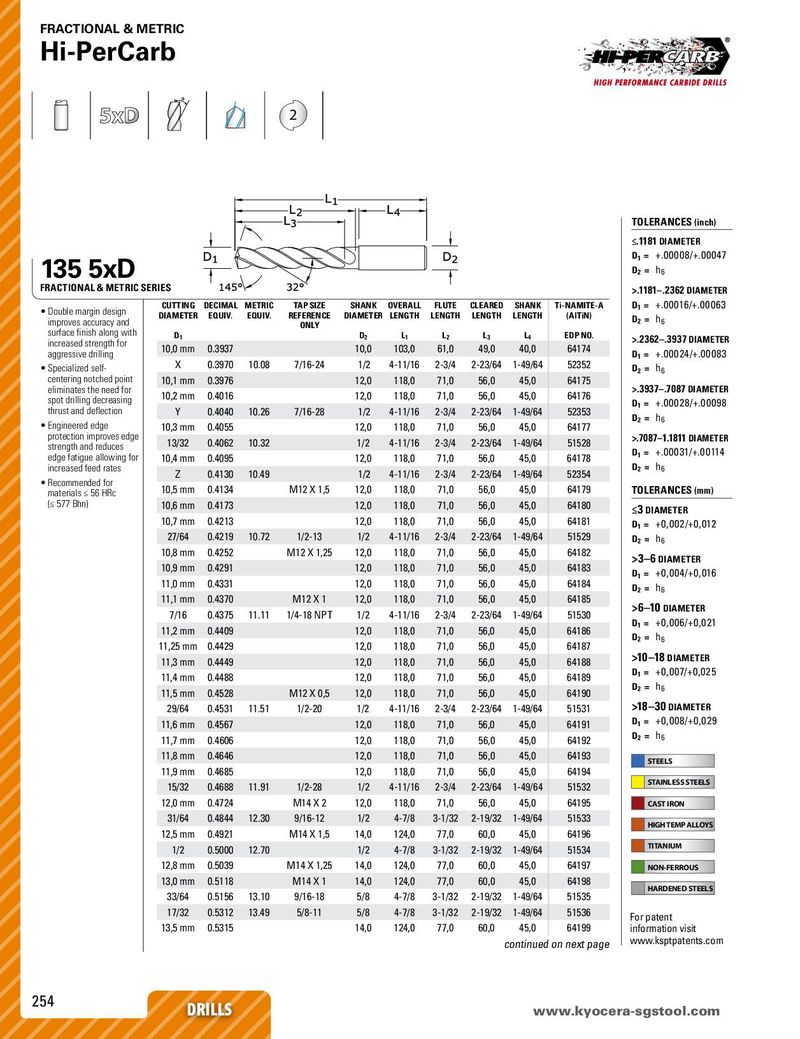

FRACTIONAL & METRIC Hi-PerCarb 2 TOLERANCES (inch) ≤.1181 DIAMETER 135 5xD D1 = +.00008/+.00047 D2 = h6 FRACTIONAL & METRIC SERIES >.1181–.2362 DIAMETER • Double margin design CUTTING DECIMAL METRIC TAP SIZE SHANK OVERALL FLUTE CLEARED SHANK Ti-NAMITE-A D1 = +.00016/+.00063 improves accuracy and DIAMETER EQUIV. EQUIV. REFERENCE DIAMETER LENGTH LENGTH LENGTH LENGTH (AlTiN) D2 = h6 surface finish along with ONLY increased strength for D1 D2 L1 L2 L3 L4 EDP NO. >.2362–.3937 DIAMETER aggressive drilling 10,0 mm 0.3937 10,0 103,0 61,0 49,0 40,0 64174 D1 = +.00024/+.00083 • Specialized self- X 0.3970 10.08 7/16-24 1/2 4-11/16 2-3/4 2-23/64 1-49/64 52352 D2 = h6 centering notched point 10,1 mm 0.3976 12,0 118,0 71,0 56,0 45,0 64175 eliminates the need for 10,2 mm 0.4016 12,0 118,0 71,0 56,0 45,0 64176 >.3937–.7087 DIAMETER spot drilling decreasing D1 = +.00028/+.00098 thrust and deflection Y 0.4040 10.26 7/16-28 1/2 4-11/16 2-3/4 2-23/64 1-49/64 52353 D2 = h6 • Engineered edge 10,3 mm 0.4055 12,0 118,0 71,0 56,0 45,0 64177 protection improves edge 13/32 0.4062 10.32 1/2 4-11/16 2-3/4 2-23/64 1-49/64 51528 >.7087–1.1811 DIAMETER strength and reduces D1 = +.00031/+.00114 edge fatigue allowing for 10,4 mm 0.4095 12,0 118,0 71,0 56,0 45,0 64178 h6 increased feed rates Z 0.4130 10.49 1/2 4-11/16 2-3/4 2-23/64 1-49/64 52354 D2 = • Recommended for 10,5 mm 0.4134 M12 X 1,5 12,0 118,0 71,0 56,0 45,0 64179 TOLERANCES (mm) materials ≤ 56 HRc (≤ 577 Bhn) 10,6 mm 0.4173 12,0 118,0 71,0 56,0 45,0 64180 ≤3 DIAMETER 10,7 mm 0.4213 12,0 118,0 71,0 56,0 45,0 64181 D1 = + 0, 0 0 2 /+ 0, 012 27/64 0.4219 10.72 1/2-13 1/2 4-11/16 2-3/4 2-23/64 1-49/64 51529 D2 = h6 10,8 mm 0.4252 M12 X 1,25 12,0 118,0 71,0 56,0 45,0 64182 >3–6 DIAMETER 10,9 mm 0.4291 12,0 118,0 71,0 56,0 45,0 64183 D1 = +0,004/+0,016 11,0 mm 0.4331 12,0 118,0 71,0 56,0 45,0 64184 D2 = h6 11,1 mm 0.4370 M12 X 1 12,0 118,0 71,0 56,0 45,0 64185 >6–10 DIAMETER 7/16 0.4375 11.11 1/4-18 NPT 1/2 4-11/16 2-3/4 2-23/64 1-49/64 51530 D1 = +0,006/+0,021 11,2 mm 0.4409 12,0 118,0 71,0 56,0 45,0 64186 D2 = h6 11,25 mm 0.4429 12,0 118,0 71,0 56,0 45,0 64187 11,3 mm 0.4449 12,0 118,0 71,0 56,0 45,0 64188 >10–18 DIAMETER 11,4 mm 0.4488 12,0 118,0 71,0 56,0 45,0 64189 D1 = +0,007/+0,025 11,5 mm 0.4528 M12 X 0,5 12,0 118,0 71,0 56,0 45,0 64190 D2 = h6 29/64 0.4531 11.51 1/2-20 1/2 4-11/16 2-3/4 2-23/64 1-49/64 51531 >18–30 DIAMETER 11,6 mm 0.4567 12,0 118,0 71,0 56,0 45,0 64191 D1 = +0,008/+0,029 11,7 mm 0.4606 12,0 118,0 71,0 56,0 45,0 64192 D2 = h6 11,8 mm 0.4646 12,0 118,0 71,0 56,0 45,0 64193 STEELS 11,9 mm 0.4685 12,0 118,0 71,0 56,0 45,0 64194 15/32 0.4688 11.91 1/2-28 1/2 4-11/16 2-3/4 2-23/64 1-49/64 51532 STAINLESS STEELS 12,0 mm 0.4724 M14 X 2 12,0 118,0 71,0 56,0 45,0 64195 CAST IRON 31/64 0.4844 12.30 9/16-12 1/2 4-7/8 3-1/32 2-19/32 1-49/64 51533 HIGH TEMP ALLOYS 12,5 mm 0.4921 M14 X 1,5 14,0 124,0 77,0 60,0 45,0 64196 1/2 0.5000 12.70 1/2 4-7/8 3-1/32 2-19/32 1-49/64 51534 TITANIUM 12,8 mm 0.5039 M14 X 1,25 14,0 124,0 77,0 60,0 45,0 64197 NON-FERROUS 13,0 mm 0.5118 M14 X 1 14,0 124,0 77,0 60,0 45,0 64198 HARDENED STEELS 33/64 0.5156 13.10 9/16-18 5/8 4-7/8 3-1/32 2-19/32 1-49/64 51535 17/32 0.5312 13.49 5/8-11 5/8 4-7/8 3-1/32 2-19/32 1-49/64 51536 For patent 13,5 mm 0.5315 14,0 124,0 77,0 60,0 45,0 64199 information visit continued on next page www.ksptpatents.com 254 DRILLS www.kDyRoIcLeLrSa-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском