Каталог SGS инструмент для обработки алюминия - страница 3

Навигация

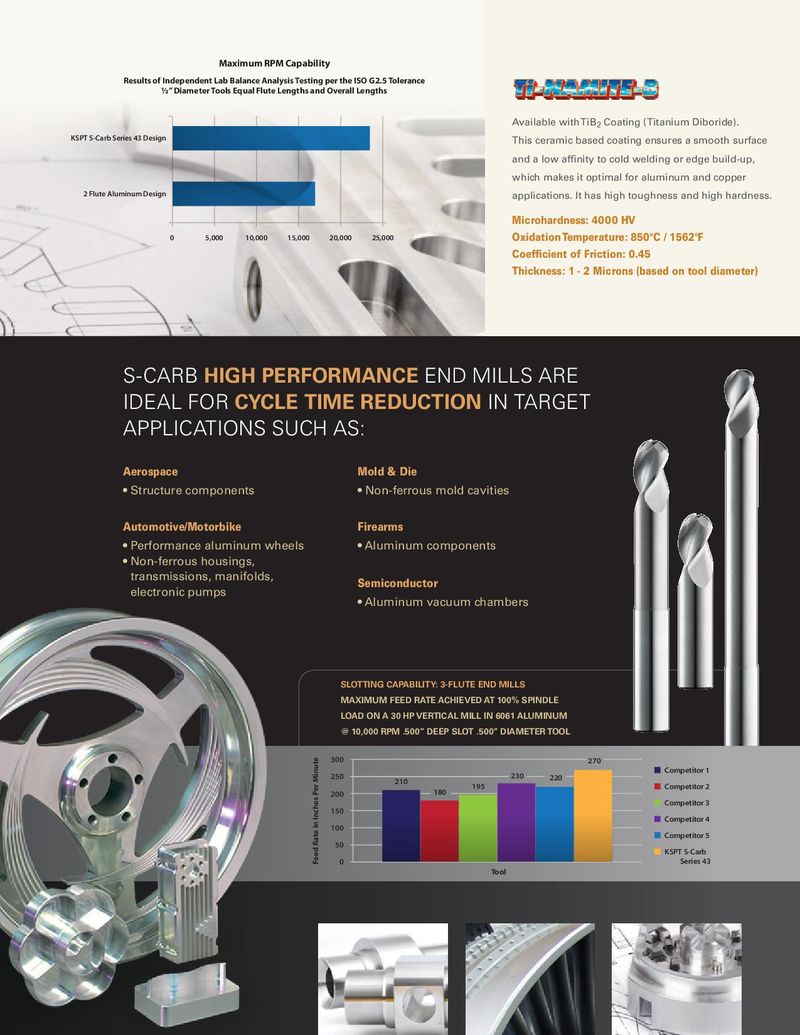

Maximum RPM Capability Results of Independent Lab Balance Analysis Testing per the ISO G2.5 Tolerance ½” Diameter Tools Equal Flute Lengths and Overall Lengths Available with TiB2 Coating (Titanium Diboride). KSPT S-Carb Series 43 Design This ceramic based coating ensures a smooth surface and a low affinity to cold welding or edge build-up, which makes it optimal for aluminum and copper 2 Flute Aluminum Design applications. It has high toughness and high hardness. Microhardness: 4000 HV 0 5,000 10,000 15,000 20,000 25,000 Oxidation Temperature: 850°C / 1562°F Coefficient of Friction: 0.45 Thickness: 1 - 2 Microns (based on tool diameter) S-CARB HIGH PERFORMANCE END MILLS ARE IDEAL FOR CYCLE TIME REDUCTION IN TARGET APPLICATIONS SUCH AS: Aerospace Mold & Die • Structure components • Non-ferrous mold cavities Automotive/Motorbike Firearms • Performance aluminum wheels • Aluminum components • Non-ferrous housings, transmissions, manifolds, Semiconductor electronic pumps • Aluminum vacuum chambers SLOTTING CAPABILITY: 3-FLUTE END MILLS MAXIMUM FEED RSlAoTtEtiAnCgHCIEaVpaEbDiAliTty1:030-%FluStPeINEDnLdEMills LOAD ON A 30 HP VERTICAL MILL IN 6061 ALUMINUM Maximum Feed Rate Achieved at 100% Spindle Load on a 30 hp Vertical Mill @ 10In,060006R1PAMlu.m50in0u”mDE@E1P0S,0L0O0Trp.5m00.”50D0I”ADMeEeTpESRloTtO.O50L0” Diameter Tool Feed Rate in Inches Per Minute 300 270 250 230 Competitor 1 210 220 180 195 Competitor 2 200 Competitor 3 150 Competitor 4 100 Competitor 5 50 KSPT S-Carb 0 Series 43 Tool

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы с переменным углом спирали Z-carb

Каталог SGS фрезы с переменным углом спирали Z-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb