Общий каталог PRECITOOL - страница 609

Навигация

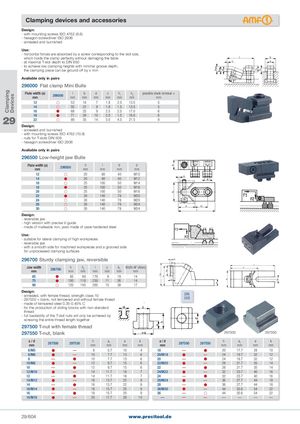

Clamping Devices Clamping devices and accessories Design: - with mounting screws ISO 4762 (8.8) - hexagon screwdriver ISO 2936 - annealed and burnished Use: - horizontal forces are absorbed by a screw corresponding to the slot size, which holds the clamp perfectly without damaging the table - at maximal T-slot depth to DIN 650 - to achieve low clamping heights with minimal groove depth, the clamping piece can be ground off by x mm Available only in pairs 296000 Flat clamp Mini Bulle Flute width (a)mm 296000 lmm bmm dmm cmm h1mm h2mm possible stock removal × mm 12 52 18 7 1.8 2.5 13.5 5 14 55 22 8 1.8 1.5 13.5 5 16 68 25 9 2.5 2.5 17.0 6 18 71 28 10 2.5 1.5 16.0 6 29 22 89 35 14 3.0 4.5 21.5 9 Design: - annealed and burnished - with mounting screws ISO 4762 (10.9) - nuts for T-slots DIN 508 - hexagon screwdriver ISO 2936 Available only in pairs 296500 Low-height jaw Bulle Flute width (a)mm 296500 h l bmmmmmm dmm 12 20 80 40 M10 14 20 80 40 M12 16 25 100 50 M14 18 25 100 50 M16 20 25 100 50 M16 22 30 140 78 M20 24 30 140 78 M20 28 30 140 78 M24 30 30 140 78 M24 Design: - reversible jaw - high version with precise V-guide - made of malleable iron, jaws made of case-hardened steel Use: - suitable for lateral clamping of high workpieces - reversible jaw - with a smooth side for machined workpieces and a grooved side for unprocessed clamping surfaces 296700 Sturdy clamping jaw, reversible Jaw widthmm 296700 hmm h2mm lmm cmm b1 Width AF (Allen)mmmm 65 85 99 179 8 19 14 75 100 118 230 11 26 14 90 120 145 265 15 38 17 Design:- annealed, with female thread, strength class 10- 297550 = blank, not tempered and without female thread DIN508 - made of tempered steel 0.35-0.45% C 1 - for the production of sliding blocks with non-standard thread - full loadability of the T-slot nuts will only be achieved by screwing the entire thread length together 297500 T-nut with female thread 297550 T-nut, blank 297500 297550 a/dmm 297500 297550 hmm a1mm emm kmm a/dmm 297500 297550 hmm a1mm emm kmm 6/M5 — 8 5.7 10 4 18 — 20 17.7 28 10 8/M6 — 10 7.7 13 6 20/M18 — 24 19.7 32 12 8 — 10 7.7 13 6 20 — 24 19.7 32 12 10/M8 — 12 9.7 15 6 22/M20 — 28 21.7 35 14 10 — 12 9.7 15 6 22 — 28 21.7 35 14 12/M10 — 14 11.7 18 7 24/M22 — 32 23.7 40 16 12 — 14 11.7 18 7 24 — 32 23.7 40 16 14/M12 — 16 13.7 22 8 28/M24 — 36 27.7 44 18 14 — 16 13.7 22 8 28 — 36 27.7 44 18 16/M14 — 18 15.7 25 9 36/M30 — 44 35.6 54 22 16 — 18 15.7 25 9 36 — 44 35.6 54 22 18/M16 — 20 17.7 28 10 — — — — — — — 29/604 www.precitool.de