Общий каталог OSG 2018 - 2019 - страница 999

Навигация

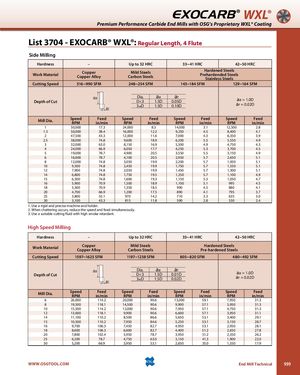

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3704 - EXOCARB® WXL®: Regular Length, 4 Flute Side Milling Hardness – Up to 32 HRC 33~41 HRC 42~50 HRC Work Material CopperCopper Alloy Mild SteelsCarbon Steels Hardened SteelsPrehardended SteelsStainless Steels Cutting Speed 516~990 SFM 248~254 SFM 143~184 SFM 129~164 SFM Depth of Cut Dia. aa arD<31.5D0.05D3≤D1.5D0.10D aa = 1.0Dar = 0.02D Mill Dia. Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/min 1 50,000 17.3 24,000 8.3 14,000 3.1 12,500 2.8 1.5 50,000 38.4 16,000 12.2 9,250 4.5 8,400 4.1 2 47,500 43.3 12,000 11.6 7,000 4.3 6,350 3.9 2.5 38,000 74.8 9,600 18.9 6,200 5.5 5,550 4.9 3 32,000 63.0 8,150 16.9 5,300 4.9 4,750 4.3 4 24,000 66.9 6,050 17.7 4,250 5.3 3,700 4.5 5 19,000 78.7 4,900 20.5 3,550 5.5 3,150 4.9 6 16,000 78.7 4,100 20.5 2,950 5.7 2,650 5.1 8 12,000 74.8 3,050 19.9 2,200 5.7 1,950 5.1 10 9,500 74.8 2,450 19.9 1,750 5.7 1,550 5.1 12 7,900 74.8 2,050 19.9 1,450 5.7 1,300 5.1 14 6,800 74.8 1,750 19.5 1,250 5.7 1,100 4.9 15 6,300 74.8 1,600 19.3 1,150 5.3 1,050 4.7 16 5,900 70.9 1,500 18.9 1,100 5.1 995 4.5 18 5,300 70.9 1,350 18.5 990 4.5 880 4.1 20 4,700 66.9 1,200 17.5 890 4.1 795 3.7 25 3,800 55.1 970 14.2 710 3.3 635 3.0 30 3,100 43.3 815 11.8 590 2.8 530 2.4 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Speed Milling Hardness – Up to 32 HRC 33~41 HRC 42~50 HRC Work Material CopperCopper Alloy Mild SteelsCarbon Steels Hardened SteelsPre-hardened Steels Cutting Speed 1597~1625 SFM 1197~1238 SFM 805~820 SFM 480~492 SFM Depth of Cut Dia. aa arD<31.5D0.01D3≤D1.5D0.02D aa = 1.0Dar = 0.02D Mill Dia. Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/min 6 26,000 114.2 20,000 90.6 13,000 59.1 7,950 31.3 8 19,500 118.1 14,500 90.6 9,900 57.1 5,950 31.3 10 15,500 114.2 12,000 90.6 7,950 57.1 4,750 31.3 12 13,000 118.1 9,900 90.6 6,600 57.1 3,950 31.1 14 11,100 110.2 8,500 86.6 5,650 53.1 3,400 29.1 15 10,500 110.2 7,950 84.6 5,250 53.1 3,150 28.7 16 9,700 106.3 7,450 82.7 4,950 53.1 2,950 28.1 18 8,600 106.3 6,600 82.7 4,400 51.2 2,650 27.8 20 7,800 102.4 5,950 78.7 3,950 51.2 2,350 26.2 25 6,200 78.7 4,750 63.0 3,150 41.3 1,900 22.0 30 5,200 66.9 3,950 53.1 2,650 35.0 1,550 17.9 WWW.OSGTOOL.COM End Mill Technical 999

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta