Общий каталог OSG 2018 - 2019 - страница 993

Навигация

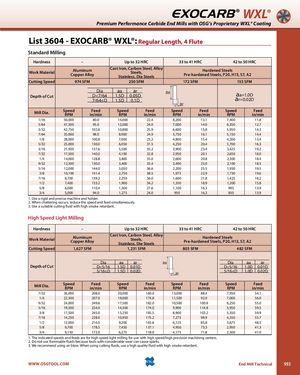

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3604 - EXOCARB® WXL®: Regular Length, 4 Flute Standard Milling Hardness – Up to 32 HRC 33 to 41 HRC 42 to 50 HRC Work Material AluminumCopper Alloy Cast Iron, Carbon Steel, AlloySteels,Stainless, Die Steels Hardened SteelsPre-hardened Steels, P20, H13, S7, A2 Cutting Speed 974 SFM 250 SFM 172 SFM 153 SFM Dia aa arDepth of CutD<7/641.5D0.05D7/64≤D1.5D0.1D aa=1.0Dar=0.02D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 1/16 50,000 80.0 14,000 22.4 8,200 13.1 7,400 11.8 5/64 47,500 95.0 12,000 24.0 7,000 14.0 6,350 12.7 3/32 42,750 102.6 10,800 25.9 6,600 15.8 5,950 14.3 7/64 35,000 98.0 8,900 24.9 5,750 16.1 5,150 14.4 1/8 28,000 100.8 7,000 25.2 4,800 15.4 4,200 13.4 5/32 25,000 130.0 6,050 31.5 4,250 20.4 3,700 16.3 3/16 21,500 137.6 5,500 35.2 3,900 23.4 3,425 19.2 7/32 17,500 140.0 4,100 32.8 2,950 20.1 2,650 18.0 1/4 14,000 128.8 3,800 35.0 2,600 20.8 2,300 18.4 9/32 12,500 130.0 3,400 35.4 2,400 23.0 2,100 18.5 5/16 12,000 144.0 3,050 36.6 2,200 25.5 1,950 19.5 3/8 10,100 141.4 2,750 38.5 1,975 22.9 1,750 19.6 7/16 8,700 139.2 2,250 36.0 1,600 21.8 1,425 18.2 1/2 7,400 133.2 1,900 34.2 1,350 18.9 1,200 15.8 5/8 6,000 110.4 1,500 27.6 1,100 16.3 995 13.9 3/4 5,000 94.0 1,275 24.0 950 16.3 850 13.9 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Speed Light Milling Hardness – Up to 32 HRC 33 to 41 HRC 42 to 50 HRC Work Material AluminumCopper Alloy Cast Iron, Carbon Steel, AlloySteels,Stainless, Die Steels Hardened SteelsPre-hardened Steels, P20, H13, S7, A2 Cutting Speed 1,627 SFM 1,231 SFM 803 SFM 482 SFM Dia aa ar Dia aa ar Depth of Cut D<5/16 1.5D 0.01D D<5/16 1.0D 0.01D 5/16≤D 1.5D 0.02D 5/16≤D 1.0D 0.02D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 7/32 26,000 208.0 20,000 160.0 13,000 88.4 7,950 54.1 1/4 22,500 207.0 19,000 174.8 11,500 92.0 7,000 56.0 9/32 24,000 249.6 17,500 182.0 10,500 100.8 6,250 55.0 5/16 19,500 234.0 14,500 174.0 9,900 114.8 5,950 59.5 3/8 17,500 245.0 13,250 185.5 8,900 103.2 5,350 59.9 7/16 14,250 228.0 10,950 175.2 7,275 98.9 4,350 55.7 1/2 12,000 216.0 9,200 165.6 6,125 85.8 3,675 48.5 5/8 9,700 178.5 7,450 137.1 4,950 73.3 2,950 41.3 3/4 9,150 172.0 6,275 118.0 4,175 71.8 2,500 41.0 1. The indicated speeds and feeds are for high speed light milling for use with high speed/high precision machining centers. 2. Do not use flammable fluids because tools with considerable wear can cause sparks. 3. We recommend using air blow. When using cutting fluids, use a high quality fluid with high smoke retardant. WWW.OSGTOOL.COM End Mill Technical 993

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta