Общий каталог OSG 2018 - 2019 - страница 986

Навигация

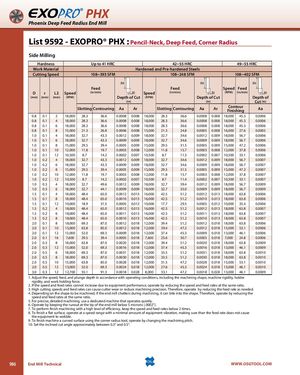

PHX Phoenix Deep Feed Radius End Mill List 9592 - EXOPRO® PHX : Pencil-Neck, Deep Feed, Corner Radius Side Milling Hardness Up to 41 HRC 42~55 HRC 49~55 HRC Work Material Hardened and Pre-hardened Steels Cutting Speed 108~393 SFM 108~248 SFM 108~402 SFM Feed Feed Speed Feed D r L2 Speed (in/min) Speed (in/min) (RPM) (in/min) (mm) (mm) (mm) (RPM) Depth of Cut (RPM) Depth of Cut Depth of (in) (in) Cut (in) Slotting Contouring Aa Ar Slotting Contouring Aa Ar ContourFinishing Aa 0.8 0.1 2 18,000 28.3 36.6 0.0008 0.008 18,000 28.3 36.6 0.0008 0.008 18,000 45.3 0.0006 0.8 0.1 4 18,000 28.3 36.6 0.0008 0.008 18,000 28.3 36.6 0.0008 0.008 18,000 45.3 0.0006 0.8 0.1 6 18,000 28.3 36.6 0.0008 0.008 18,000 28.3 36.6 0.0008 0.008 18,000 45.3 0.0006 0.8 0.1 8 15,000 21.3 26.8 0.0006 0.008 15,000 21.3 24.8 0.0005 0.008 16,000 27.6 0.0005 1.0 0.1 4 18,000 32.7 43.3 0.0012 0.009 18,000 32.7 34.6 0.0012 0.009 18,000 56.7 0.0006 1.0 0.1 6 18,000 32.7 43.3 0.0009 0.009 18,000 32.7 34.6 0.0009 0.009 18,000 56.7 0.0006 1.0 0.1 8 15,000 29.5 39.4 0.0005 0.009 15,000 29.5 31.5 0.0005 0.009 15,000 47.2 0.0006 1.0 0.1 10 12,000 11.8 19.7 0.0003 0.008 12,000 11.8 15.7 0.0003 0.008 12,000 37.8 0.0006 1.0 0.1 12 10,500 8.7 14.2 0.0002 0.007 10,500 8.7 11.3 0.0002 0.007 10,500 33.1 0.0006 1.0 0.2 4 18,000 32.7 43.3 0.0012 0.009 18,000 32.7 34.6 0.0012 0.009 18,000 56.7 0.0007 1.0 0.2 6 18,000 32.7 43.3 0.0009 0.009 18,000 32.7 34.6 0.0009 0.009 18,000 56.7 0.0007 1.0 0.2 8 15,000 29.5 39.4 0.0005 0.009 15,000 29.5 31.5 0.0005 0.009 15,000 47.2 0.0007 1.0 0.2 10 12,000 11.8 19.7 0.0003 0.008 12,000 11.8 15.7 0.0003 0.008 12,000 37.8 0.0007 1.0 0.2 12 10,500 8.7 14.2 0.0002 0.007 10,500 8.7 11.4 0.0002 0.007 10,500 33.1 0.0007 1.0 0.3 4 18,000 32.7 49.6 0.0012 0.009 18,000 32.7 39.4 0.0012 0.009 18,000 56.7 0.0009 1.0 0.3 6 18,000 32.7 44.1 0.0009 0.009 18,000 32.7 35.0 0.0009 0.009 18,000 56.7 0.0009 1.5 0.1 4 18,000 48.4 65.0 0.0012 0.013 16,000 42.5 51.2 0.0012 0.013 18,000 63.8 0.0006 1.5 0.1 8 18,000 48.4 65.0 0.0010 0.013 16,000 42.5 51.2 0.0010 0.013 18,000 63.8 0.0006 1.5 0.1 12 10,000 18.9 31.5 0.0005 0.012 10,000 17.7 29.5 0.0005 0.012 10,000 35.4 0.0006 1.5 0.2 4 18,000 48.4 65.0 0.0012 0.013 16,000 42.5 51.2 0.0012 0.013 18,000 63.8 0.0007 1.5 0.2 6 18,000 48.4 65.0 0.0011 0.013 16,000 42.5 51.2 0.0011 0.013 18,000 63.8 0.0007 1.5 0.2 8 18,000 48.4 65.0 0.0010 0.013 16,000 42.5 51.2 0.0010 0.013 18,000 63.8 0.0007 2.0 0.1 8 18,000 69.3 87.0 0.0012 0.018 12,000 39.4 51.2 0.0012 0.018 18,000 63.8 0.0006 2.0 0.1 10 15,000 63.8 85.0 0.0012 0.018 12,000 39.4 47.2 0.0012 0.018 15,000 53.1 0.0006 2.0 0.1 12 13,000 52.0 69.3 0.0009 0.018 12,000 37.4 45.3 0.0009 0.018 13,000 46.1 0.0006 2.0 0.1 16 7,600 29.5 39.4 0.0005 0.018 7,600 23.6 30.7 0.0005 0.018 7,000 24.8 0.0006 2.0 0.3 8 18,000 63.8 87.0 0.0020 0.018 12,000 39.4 51.2 0.0020 0.018 18,000 63.8 0.0009 2.0 0.3 12 13,000 52.0 69.3 0.0016 0.018 12,000 37.4 45.3 0.0016 0.018 13,000 46.1 0.0009 2.0 0.5 6 18,000 69.3 87.0 0.0031 0.018 12,000 33.5 51.2 0.0031 0.018 18,000 63.8 0.0010 2.0 0.5 8 18,000 69.3 87.0 0.0030 0.018 12,000 33.5 51.2 0.0030 0.018 18,000 63.8 0.0010 2.0 0.5 10 15,000 63.8 85.0 0.0028 0.018 12,000 31.5 47.2 0.0028 0.018 15,000 53.1 0.0010 2.0 0.5 12 13,000 52.0 69.3 0.0024 0.018 12,000 27.6 45.3 0.0024 0.018 13,000 46.1 0.0010 3.0 0.3 12 12,700 55.1 91.3 0.0018 0.028 8,000 33.1 47.2 0.0018 0.028 13,000 46.1 0.0009 1. Adjust the speed, feed, and plunge depth in accordance with operating conditions, including the machining shape, machine rigidity, holder rigidity, and work holding force. 2. If the speed and feed rates cannot increase due to equipment performance, operate by reducing the speed and feed rates at the same ratio. 3. High cutting speeds and feed rates can cause cutter wear or reduce machining precision. Therefore, operate by reducing the feed rate as needed. 4. Depending on the shape to be machined, if the end mill chatters during machining, it can bite into the shape. Therefore, operate by reducing the speed and feed rates at the same ratio. 5. For precise, detailed machining, use a dedicated machine that operates quietly. 6. Operate by keeping the runout at the tip of the end mill below 5 microns (.0002’’). 7. To perform finish machining with a high level of efficiency, keep the speed and feed rates below 2 times. 8. To finish a flat surface, operate at a speed range with a minimal amount of equipment vibration, making sure than the feed rate does not cause the equipment to wobble. 9. To finish machine a curved surface using the corner radius tool, operate by changing the machining pitch. 10. Set the inclined cut angle approximately between 0.3° and 0.5°. 986 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta