Общий каталог OSG 2018 - 2019 - страница 952

Навигация

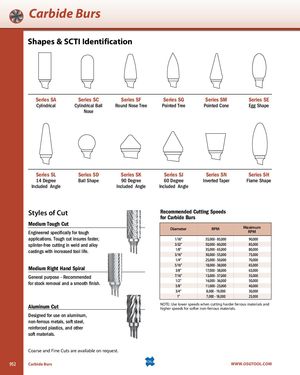

Carbide Burs Shapes & SCTI Identification Series SA Series SC Series SF Series SG Series SM Series SE Cylindrical Cylindrical Ball Round Nose Tree Pointed Tree Pointed Cone Egg Shape Nose Series SL Series SD Series SK Series SJ Series SN Series SH 14 Degree Ball Shape 90 Degree 60 Degree Inverted Taper Flame Shape Included Angle Included Angle Included Angle Styles of Cut Recommended Cutting Speeds for Carbide Burs Medium Tough Cut Engineered specifically for tough Diameter RPM MaximumRPM applications. Tough cut insures faster, 1/16” 55,000 - 85,000 90,000 splinter-free cutting in weld and alloy 3/32” 50,000 - 60,000 85,000 castings with increased tool life. 1/8” 35,000 - 65,000 80,000 3/16” 30,000 - 55,000 75,000 1/4” 25,000 - 50,000 70,000 Medium Right Hand Spiral 5/16” 18,000 - 38,000 65,0003/8”17,000 - 38,00063,000 General purpose - Recommended 7/16” 13,000 - 37,000 55,000 for stock removal and a smooth finish. 1/2” 14,000 - 36,000 50,0005/8”11,000 - 23,00040,000 3/4” 8,000 - 19,000 30,000 1” 7,000 - 18,000 25,000 Aluminum Cut NOTE: Use lower speeds when cutting harder ferrous materials andhigher speeds for softer non-ferrous materials. Designed for use on aluminum, non-ferrous metals, soft steel, reinforced plastics, and other soft materials. Coarse and Fine Cuts are available on request. 952 Carbide Burs WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta