Общий каталог OSG 2018 - 2019 - страница 557

Навигация

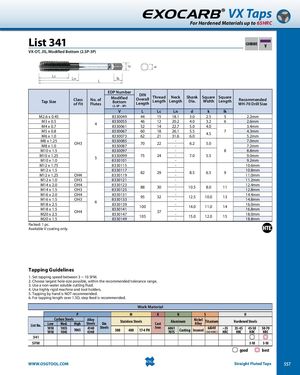

d k EXOCARB® VX Taps For Hardened Materials up to 65HRC List 341 CARBIDE V VX-OT, JIS, Modified Bottom (2.5P-3P) Lc Ln L lk EDP Number Tap Size Class No. ofof FitFlutesModifiedBottom(2.5P - 3P)DINOverallLengthThreadLengthNeckLengthShankDia.SquareSquareWidthLengthRecommendedWH-70 Drill Size V L Lc Ln d k lk M2.6 x 0.45 8330049 44 15 18.1 3.0 2.5 5 2.2mm M3 x 0.5M4 x 0.7 4 8330055 46 12 20.2 4.0 3.2 68330061521422.75.04.02.6mm3.4mm M5 x 0.8M6 x 1.0 83300678330073 6062 1821 26.1 5.531.66.0 4.5 7 4.3mm5.2mm M8 x 1.25M8 x 1.0 OH3 83300858330087 70 22 -- 6.2 5.0 7.0mm7.2mm M10 x 1.5 8330097 - 8 8.8mm M10 x 1.25M10 x 1.0 5 8330099 75 24 - 7.0 5.58330101- 9.0mm9.2mm M12 x 1.75 8330115 - 10.6mm M12 x 1.5M12 x 1.25 OH4 83301178330119 82 29 -- 8.5 6.5 9 10.8mm11.0mm M12 x 1.0 OH3 8330121 - 11.2mm M14 x 2.0 OH4M14 x 1.5OH3 83301238330125 88 30 -- 10.5 8.0 11 12.4mm12.8mm M16 x 2.0M16 x 1.5M18 x 2.5M18 x 1.5M20 x 2.5M20 x 1.5OH4OH36OH4833013183301339532 -- 12.5 10.0 13833013983301418330147833014910037105--14.011.014--15.012.01514.4mm14.8mm16.0mm16.8mm18.0mm18.8mm Packed: 1 pc. Available V coating only. Tapping Guidelines 1. Set tapping speed between 3 ~ 10 SFM. 2. Choose largest hole-size possible, within the recommended tolerance range. 3. Use a non-water soluble cutting fluid. 4. Use highly rigid machine and tool holders. 5. Tapping by hand is NOT recommended. 6. For tapping length over 1.5D, step feed is recommended. Work Material P M K N S H Carbon Steels AlloyList No.Low10101018Med.10351045HighSteelsDie10654140Steels4340Stainless SteelsCast30040017-4 PHIronAluminumNickelAlloyTitaniumHardened Steels60617075CastingInconel6Al4V(30 HRC)~35HRC35-4545-5050-70HRCHRCHRC 341 SFM 3-10 3-10 good best WWW.OSGTOOL.COM Straight Fluted Taps 557

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta