Общий каталог OSG 2018 - 2019 - страница 304

Навигация

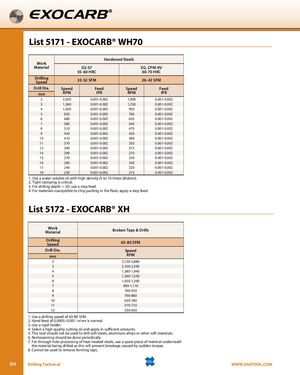

EXOCARB® List 5171 - EXOCARB® WH70 Hardened Steels Work Material D2-S7 D2, CPM-9V 55-60 HRC 60-70 HRC DrillingSpeed 33-52 SFM 26-42 SFM Drill Dia. Speed Feed Speed Feed mm RPM IPR RPM IPR 2 2,050 0.001-0.002 1,900 0.001-0.002 3 1,360 0.001-0.002 1,250 0.001-0.002 4 1,020 0.001-0.002 950 0.001-0.002 5 820 0.001-0.002 760 0.001-0.002 6 680 0.001-0.002 630 0.001-0.002 7 580 0.001-0.002 540 0.001-0.002 8 510 0.001-0.002 470 0.001-0.002 9 450 0.001-0.002 420 0.001-0.002 10 410 0.001-0.002 380 0.001-0.002 11 370 0.001-0.002 350 0.001-0.002 12 340 0.001-0.002 315 0.001-0.002 14 290 0.001-0.002 270 0.001-0.002 15 270 0.001-0.002 250 0.001-0.002 16 260 0.001-0.002 240 0.001-0.002 17 240 0.001-0.002 220 0.001-0.002 18 230 0.001-0.002 210 0.001-0.002 1. Use a water soluble oil with high density (5 to 10 times dilution). 2. Tight clamping is critical. 3. For drilling depth > 3D, use a step feed. 4. For materials susceptible to chip packing in the flute, apply a step feed. List 5172 - EXOCARB® XH WorkMaterial Broken Taps & Drills DrillingSpeed 65-80 SFM Drill Dia. Speed mm RPM 2 3,150-3,880 3 2,100-2,590 4 1,580-1,940 5 1,260-1,550 6 1,050-1,290 7 900-1,110 8 790-970 9 700-860 10 630-780 11 570-710 12 530-650 1. Use a drilling speed of 65-80 SFM. 2. Hand feed of 0.0005~0.001 in/rev is normal. 3. Use a rigid holder. 4. Select a high quality cutting oil and apply in sufficient amounts. 5. This tool should not be used to drill soft steels, aluminum alloys or other soft materials. 6. Resharpening should be done periodically. 7. For through hole processing of heat treated steels, use a spare piece of material underneath the material being drilled as this will prevent breakage caused by sudden torque. 8. Cannot be used to remove forming taps. 304 Drilling Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta