Общий каталог OSG 2018 - 2019 - страница 295

Навигация

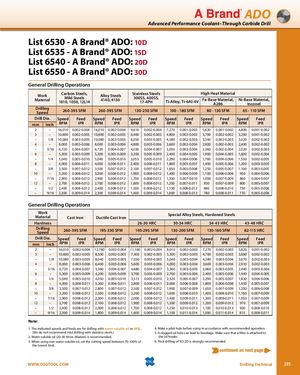

ADO Advanced Performance Coolant–Through Carbide Drill List 6530 - A Brand® ADO: 10D List 6535 - A Brand® ADO: 15D List 6540 - A Brand® ADO: 20D List 6550 - A Brand® ADO: 30D General Drilling Operations WorkMaterial Carbon Steels,Mild Steels1010, 1050, 12L14Alloy Steels4140, 4130Stainless Steels High Heat Material300SS, 400SS,17-4PHTi-Alloy, Ti-6Al-4VFe-Base Material,A286Ni-Base Material,Inconel DrillingSpeed 260-395 SFM 260-395 SFM 130-230 SFM 100 - 180 SFM 80 - 130 SFM 65 - 110 SFM Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 16,010 0.002-0.004 16,010 0.002-0.004 9,610 0.002-0.004 7,270 0.001-0.003 5,630 0.001-0.002 4,800 0.001-0.002 3 – 10,600 0.002-0.005 10,600 0.002-0.005 6,400 0.002-0.005 4,800 0.002-0.003 3,700 0.002-0.002 3,200 0.001-0.002 – 1/8 10,080 0.003-0.005 10,080 0.003-0.005 6,050 0.003-0.005 4,580 0.002-0.003 3,540 0.002-0.003 3,020 0.002-0.002 4 – 8,000 0.003-0.006 8,000 0.003-0.006 4,800 0.003-0.006 3,600 0.002-0.004 2,800 0.002-0.003 2,400 0.002-0.002 – 3/16 6,720 0.004-0.007 6,720 0.004-0.007 4,030 0.004-0.007 3,050 0.003-0.004 2,360 0.002-0.004 2,020 0.002-0.003 6 – 5,300 0.005-0.009 5,300 0.005-0.009 3,200 0.005-0.009 2,400 0.004-0.005 1,900 0.004-0.005 1,600 0.002-0.004 – 1/4 5,040 0.005-0.010 5,040 0.005-0.010 3,055 0.005-0.010 2,290 0.004-0.006 1,760 0.004-0.006 1,530 0.002-0.005 8 – 4,000 0.006-0.011 4,000 0.006-0.011 2,400 0.006-0.011 1,800 0.005-0.007 1,400 0.005-0.006 1,200 0.003-0.005 – 3/8 3,500 0.007-0.012 3,500 0.007-0.012 2,100 0.007-0.012 1,650 0.005-0.008 1,250 0.005-0.007 1,100 0.003-0.005 10 – 3,200 0.008-0.012 3,200 0.008-0.012 1,900 0.008-0.012 1,400 0.006-0.009 1,100 0.006-0.008 950 0.004-0.006 – 7/16 2,900 0.008-0.012 2,900 0.008-0.012 1,700 0.008-0.012 1,300 0.007-0.010 1,000 0.007-0.009 860 0.004-0.007 12 – 2,700 0.008-0.012 2,700 0.008-0.012 1,600 0.008-0.012 1,200 0.007-0.011 930 0.007-0.009 800 0.005-0.007 – 1/2 2,400 0.008-0.012 2,400 0.008-0.012 1,500 0.008-0.012 1,100 0.008-0.012 880 0.008-0.010 750 0.005-0.008 – 9/16 2,300 0.009-0.014 2,300 0.009-0.014 1,400 0.009-0.014 1,000 0.008-0.013 780 0.008-0.011 770 0.005-0.008 General Drilling Operations WorkMaterial Cast Iron Ductile Cast Iron Special Alloy Steels, Hardened Steels Hardness 26-30 HRC 30-34 HRC 34-43 HRC 43-48 HRC DrillingSpeed 260-395 SFM 195-330 SFM 195-295 SFM 130-200 SFM 130-160 SFM 82-115 HRC Drill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed mm Inch RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR RPM IPR 2 – 16,010 0.002-0.004 12,760 0.002-0.004 11,160 0.002-0.004 8,010 0.002-0.003 7,270 0.002-0.003 5,820 0.001-0.002 3 – 10,600 0.002-0.005 8,500 0.002-0.005 7,400 0.002-0.005 5,300 0.002-0.003 4,700 0.002-0.003 3,880 0.002-0.002 – 1/8 10,080 0.003-0.005 8,040 0.003-0.005 7,030 0.003-0.005 5,040 0.003-0.004 4,580 0.003-0.004 3,670 0.002-0.003 4 – 8,000 0.003-0.006 6,400 0.003-0.006 5,600 0.003-0.006 4,000 0.003-0.004 3,600 0.003-0.004 2,910 0.002-0.003 – 3/16 6,720 0.004-0.007 5,360 0.004-0.007 4,680 0.004-0.007 3,360 0.003-0.005 3,060 0.003-0.005 2,440 0.003-0.004 6 – 5,300 0.005-0.009 4,200 0.005-0.009 3,700 0.005-0.009 2,700 0.005-0.006 2,400 0.005-0.006 1,940 0.004-0.005 – 1/4 5,040 0.005-0.010 4,050 0.005-0.010 3,515 0.005-0.010 2,520 0.005-0.007 2,290 0.005-0.007 1,830 0.004-0.006 8 – 4,000 0.006-0.011 3,200 0.006-0.011 2,800 0.006-0.011 2,000 0.006-0.008 1,800 0.006-0.008 1,450 0.005-0.007 – 3/8 3,500 0.007-0.012 2,800 0.007-0.012 2,500 0.007-0.012 1,900 0.007-0.009 1,650 0.007-0.009 1,330 0.006-0.008 10 – 3,200 0.008-0.012 2,500 0.008-0.012 2,200 0.008-0.012 1,600 0.008-0.010 1,400 0.008-0.010 1,160 0.007-0.009 – 7/16 2,900 0.008-0.012 2,300 0.008-0.012 2,000 0.008-0.012 1,400 0.009-0.011 1,300 0.009-0.011 1,050 0.007-0.009 12 – 2,700 0.008-0.012 2,100 0.008-0.012 1,900 0.008-0.012 1,300 0.009-0.012 1,200 0.009-0.012 970 0.007-0.009 – 1/2 2,400 0.008-0.012 2,000 0.008-0.012 1,700 0.008-0.012 1,250 0.010-0.013 1,100 0.010-0.013 920 0.008-0.010 – 9/16 2,300 0.009-0.014 1,800 0.009-0.014 1,600 0.009-0.014 1,100 0.011-0.014 1,000 0.011-0.014 815 0.008-0.011 Note: 1. The indicated speeds and feeds are for drilling with water-soluble oil or MQL. 4. Make a pilot hole before using in accordance with recommended operation. (We do not recommend mist drilling with stainless steels.) 5. A clogged oil hole can lead to breakage. Make sure that a filter is attached to 2. Water-soluble oil (20-30 times dilution) is recommended. the oil feeder. 3. When using non-water-soluble oil, set the cutting speed between 70-100% of 6. Peck drilling of 1D-2D is strongly recommended. the lowest limit. WWW.OSGTOOL.COM Drilling Technical 295

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta