Общий каталог OSG 2018 - 2019 - страница 1300

Навигация

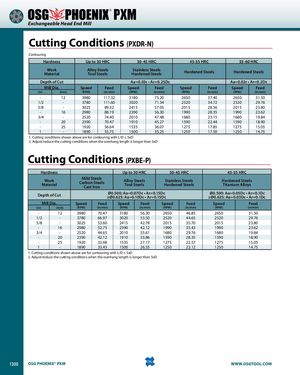

® PXM Exchangeable Head End Mill Cutting Conditions (PXDR-N) Contouring Hardness Up to 30 HRC 30-45 HRC 45-55 HRC 55-60 HRC WorkMaterial Alloy SteelsTool Steels Stainless SteelsHardened Steels Hardened Steels Hardened Steels Depth of Cut Aa=0.03r • Ar=0.25Dc Aa=0.02r • Ar=0.2Dc Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed (in) (mm) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) - 12 3980 117.32 3180 75.20 2650 37.40 2650 31.50 1/2 - 3780 111.60 3020 71.34 2520 34.72 2520 29.76 5/8 - 3025 89.32 2415 57.05 2015 28.56 2015 23.80 - 16 2980 88.19 2390 56.30 1990 28.35 1990 23.62 3/4 - 2520 74.40 2010 47.48 1680 23.15 1680 19.84 - 20 2390 70.47 1910 45.27 1590 22.44 1590 18.90 - 25 1920 56.64 1535 36.07 1275 17.85 1275 15.05 1 - 1890 55.75 1500 35.25 1250 17.50 1250 14.75 1. Cutting conditions shown above are for contouring with L/D ≤ 5xD 2. Adjust/reduce the cutting conditions when the overhang length is longer than 5xD Cutting Conditions (PXBE-P) ContouriHngardness Up to 30 HRC 30-45 HRC 45-55 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool Steels Stainless SteelsHardened Steels Hardened SteelsTitanium Alloys Depth of Cut Ø0.500: Aa=0.07Dc • Ar=0.15Dc Ø0.500: Aa=0.05Dc • Ar=0.1Dc≥Ø0.625: Aa=0.10Dc • Ar=0.15Dc≥Ø0.625: Aa=0.03Dc • Ar=0.1Dc Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed (in) (mm) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) - 12 3980 70.47 3180 56.30 2650 46.85 2650 31.50 1/2 - 3780 66.97 3020 53.50 2520 44.65 2520 29.76 5/8 - 3025 53.60 2415 42.78 2015 35.70 2015 23.80 - 16 2980 52.75 2390 42.12 1990 35.43 1990 23.62 3/4 - 2520 44.65 2010 35.61 1680 29.76 1680 19.84 - 20 2390 42.12 1910 33.86 1590 28.35 1590 18.90 - 25 1920 33.98 1535 27.17 1275 22.57 1275 15.05 1 - 1890 33.45 1500 26.55 1250 22.12 1250 14.75 1. Cutting conditions shown above are for contouring with L/D ≤ 5xD 2. Adjust/reduce the cutting conditions when the overhang length is longer than 5xD 1300 OSG PHOENIX® PXM WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta