Общий каталог OSG 2018 - 2019 - страница 1212

Навигация

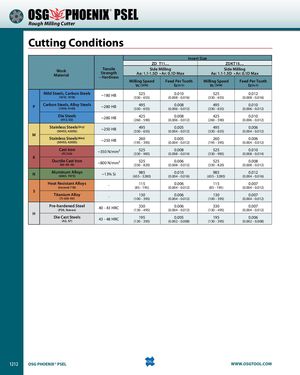

® PSEL Rough Milling Cutter Cutting Conditions Insert Size ZD_T11… ZDKT15… WorkMaterial Tensile Side Milling Side MillingStrengthAa: 1.1-1.5D • Ar: 0.1D MaxAa: 1.1-1.5D • Ar: 0.1D Max– Hardness Milling Speed Feed Per Tooth Milling Speed Feed Per Tooth Vc (SFM) fz(in/t) Vc (SFM) fz(in/t) Mild Steels, Carbon Steels(1010, 1018) ~180 HB 525(330 - 655) 0.010(0.008 - 0.016) 525(330 - 655) 0.012(0.008 - 0.016) P Carbon Steels, Alloy Steels(1050, 4140) ~280 HB 495(330 - 655) 0.008(0.006 - 0.012) 495(330 - 655) 0.010(0.006 - 0.012) Die Steels(H13, D2) ~280 HB 425(260 - 590) 0.008(0.006 - 0.012) 425(260 - 590) 0.010(0.006 - 0.012) Stainless Steels(Dry)(304SS, 420SS) ~250 HB 495(330 - 655) 0.005(0.004 - 0.012) 495(330 - 655) 0.006(0.004 - 0.012) M Stainless Steels(Wet)(304SS, 420SS) ~250 HB 260(195 - 395) 0.005(0.004 - 0.012) 260(195 - 395) 0.006(0.004 - 0.012) Cast Iron(FC250) ~350 N/mm² 525(330 - 985) 0.008(0.008 - 0.014) 525(330 - 985) 0.010(0.008 - 0.014) K Ductile Cast Iron(60-40-18) ~800 N/mm² 525(330 - 820) 0.006(0.008 - 0.012) 525(330 - 820) 0.008(0.008 - 0.012) N Aluminum Alloys(6061, 7075) ~13% Si 985(655 - 3280) 0.010(0.004 - 0.016) 985(655 - 3280) 0.012(0.004 - 0.016) Heat Resistant Alloys(Inconel 718) - 115 0.006 115 0.007(85 - 195)(0.004 - 0.012)(85 - 195)(0.004 - 0.012) S Titanium Alloy(Ti-6Al-4V) - 130 0.006 130 0.007(100 - 395)(0.004 - 0.012)(100 - 395)(0.004 - 0.012) Pre-hardened Steel(P20, Stavax) 40 - 43 HRC 330(130 - 495) 0.006(0.004 - 0.012) 330(130 - 495) 0.007(0.004 - 0.012) H Die Cast Steels(A2, S7) 43 - 48 HRC 195(130 - 395) 0.005(0.002 - 0.008) 195(130 - 395) 0.006(0.002 - 0.008) 1212 OSG PHOENIX® PSEL WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta