Общий каталог OSG 2018 - 2019 - страница 1117

Навигация

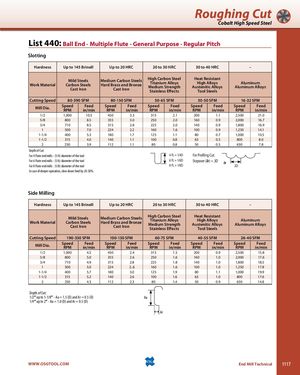

Roughing Cut Cobalt High Speed Steel List 440: Ball End - Multiple Flute - General Purpose - Regular Pitch Slotting Hardness Up to 145 Brinell Up to 20 HRC 20 to 30 HRC 30 to 40 HRC – Work Material Mild SteelsCarbon SteelsCast Iron Medium Carbon SteelsHard Brass and BronzeCast IronHigh Carbon SteelTitanium AlloysMedium StrengthStainless EffectsHeat ResistantHigh AlloysAustenitic AlloysTool SteelsAluminumAluminum Alloys Cutting Speed 80-390 SFM 80-150 SFM 50-65 SFM 30-50 SFM 16-32 SFM Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min 1/2 1,000 10.5 450 3.3 315 2.1 200 1.1 2,500 21.0 5/8 800 8.5 355 3.0 250 2.0 160 0.9 2,000 16.7 3/4 710 8.5 315 2.8 225 2.0 140 0.9 1,800 16.9 1 500 7.0 224 2.2 160 1.6 100 0.9 1,250 14.1 1-1/4 400 5.3 180 1.7 125 1.1 80 0.7 1,000 10.5 1-1/2 315 4.0 140 1.1 100 0.8 63 0.5 800 8.0 2 250 3.9 112 1.1 80 0.8 50 0.5 630 7.8 Depth of Cut: For 4 Flute end mills - (1/4) diameter of the tool 4 FL = 1/4D For Profiling Cut: For 6 Flute end mills - (1/6) diameter of the tool 6 FL = 1/6D Stepover (ar) = .3D ar For 8 Flute end mills - (1/8) diameter of the tool 8 FL = 1/8D .3D In case of deeper operation, slow down feed by 20-50%. Side Milling Hardness Up to 145 Brinell Up to 20 HRC 20 to 30 HRC 30 to 40 HRC – Work Material Mild SteelsCarbon SteelsCast Iron Medium Carbon SteelsHard Brass and BronzeCast IronHigh Carbon SteelTitanium AlloysMedium StrengthStainless EffectsHeat ResistantHigh AlloysAustenitic AlloysTool SteelsAluminumAluminum Alloys Cutting Speed 190-330 SFM 100-130 SFM 60-75 SFM 40-55 SFM 26-40 SFM Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min 1/2 1,000 4.5 450 2.4 315 1.5 200 0.9 2,500 15.8 5/8 800 5.0 355 2.6 250 1.6 160 1.0 2,000 17.6 3/4 710 4.9 315 2.8 225 1.8 140 1.0 1,800 18.5 1 500 5.0 224 2..6 160 1.6 100 1.0 1,250 17.8 1-1/4 400 5.7 180 3.0 125 1.9 80 1.1 1,000 19.9 1-1/2 315 5.2 140 2.6 100 1.6 63 1.0 800 17.6 2 250 4.3 112 2.3 80 1.4 50 0.9 630 14.8 Depth of Cut: 1/2” up to 1-1/8” - Aa = 1.5 (D) and Ar = 0.5 (D) Aa 1/4” up to 2” - Aa = 1.0 (D) and Ar = 0.5 (D) Ar WWW.OSGTOOL.COM End Mill Technical 1117

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta