Общий каталог OSG 2018 - 2019 - страница 1072

Навигация

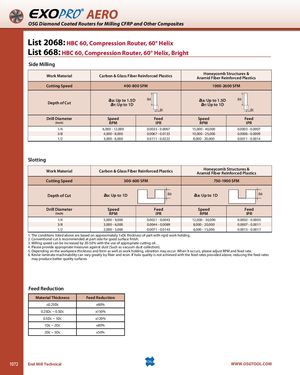

AERO OSG Diamond Coated Routers for Milling CFRP and Other Composites List 2068: HBC 60, Compression Router, 60° Helix List 668: HBC 60, Compression Router, 60° Helix, Bright Side Milling Work Material Carbon & Glass Fiber Reinforced Plastics Honeycomb Structures &Aramid Fiber Reinforced Plastics Cutting Speed 400-800 SFM 1000-2600 SFM Depth of Cut aa: Up to 1.5Dar: Up to 1D aa: Up to 1.5Dar: Up to 1D Drill Diameter Speed Feed Speed Feed (Inch) RPM IPR RPM IPR 1/4 6,000 - 12,000 0.0033 - 0.0067 15,000 - 40,000 0.0003 - 0.0007 3/8 4,000 - 8,000 0.0067 - 0.0133 10,000 - 25,000 0.0006 - 0.0009 1/2 3,000 - 6,000 0.0111 - 0.0222 8,000 - 20,000 0.0011 - 0.0014 Slotting Work Material Carbon & Glass Fiber Reinforced Plastics Honeycomb Structures &Aramid Fiber Reinforced Plastics Cutting Speed 300-600 SFM 750-1900 SFM Depth of Cut aa: Up to 1D aa: Up to 1D Drill Diameter Speed Feed Speed Feed (Inch) RPM IPR RPM IPR 1/4 5,000 - 9,000 0.0021 - 0.0043 12,000 - 30,000 0.0002 - 0.0005 3/8 3,000 - 6,000 0.0044 - 0.0089 8,000 - 20,000 0.0007 - 0.0011 1/2 2,000 - 5,000 0.0071 - 0.0143 6,000 - 15,000 0.0013 - 0.0017 1. The conditions listed above are based on approximately 1xDc thickness of part with rigid work holding. 2. Conventional cut is recommended at part side for good surface finish. 3. Milling speed can be increased by 20-50% with the use of appropriate cutting oil. 4. Please provide appropriate measures against dust (Such as vacuum dust collection). 5. Depending on the workpiece thickness and form as well as work holding, vibration may occur. When it occurs, please adjust RPM and feed rate. 6. Kevlar laminate machinability can vary greatly by fiber and resin. If hole quality is not achieved with the feed rates provided above, reducing the feed rates may produce better quality surfaces. Feed Reduction Material Thickness Feed Reduction ≤0.25Dc x80% 0.25Dc ~ 0.5Dc x150% 0.5Dc ~ 1Dc x120% 1Dc ~ 2Dc x80% 2Dc ~ 3Dc x50% 1072 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta