Общий каталог OSG 2018 - 2019 - страница 1051

Навигация

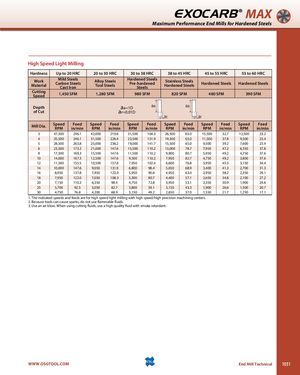

EXOCARB® MAX Maximum Performance End Mills for Hardened Steels High Speed Light Milling Hardness Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC 55 to 60 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool SteelsHardened SteelsPre-hardenedSteelsStainless SteelsHardened SteelsHardened SteelsHardened Steels CuttingSpeed 1,450 SFM 1,280 SFM 980 SFM 820 SFM 480 SFM 390 SFM Depth aa=1D of Cut ar=0.01D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 3 47,500 246.1 42,000 210.6 31,500 104.3 26,500 65.0 15,500 32.7 12,500 23.2 4 35,500 246.1 31,500 226.4 23,500 131.9 19,500 65.0 11,500 37.8 9,500 23.4 5 28,500 263.8 25,000 236.2 19,000 141.7 15,500 65.0 9,500 39.2 7,600 23.4 6 23,500 173.2 21,000 147.6 15,500 110.2 13,000 78.7 7,950 47.2 6,350 37.8 8 17,500 169.3 15,500 147.6 11,500 110.2 9,900 80.7 5,950 49.2 4,750 37.6 10 14,000 167.3 12,500 147.6 9,500 110.2 7,950 82.7 4,750 49.2 3,800 37.6 12 11,500 155.5 10,500 137.8 7,950 102.4 6,600 76.8 3,950 45.3 3,150 34.4 14 10,000 147.6 9,050 131.9 6,800 98.4 5,650 68.9 3,400 41.3 2,700 31.3 16 8,950 137.8 7,950 122.0 5,950 90.6 4,950 63.0 2,950 38.2 2,350 29.1 18 7,950 122.0 7,050 108.3 5,300 80.7 4,400 57.1 2,650 34.8 2,100 27.2 20 7,150 110.2 6,350 98.4 4,750 72.8 3,950 53.1 2,350 30.9 1,900 24.6 25 5,700 92.5 5,050 82.7 3,800 59.1 3,150 43.3 1,900 26.6 1,500 20.7 30 4,750 76.8 4,200 68.9 3,150 49.2 2,650 37.0 1,550 21.7 1,250 17.1 1. The indicated speeds and feeds are for high speed light milling with high speed/high precision machining centers. 2. Because tools can cause sparks, do not use flammable fluids. 3. Use an air blow. When using cutting fluids, use a high quality fluid with smoke retardant. WWW.OSGTOOL.COM End Mill Technical 1051

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta