Общий каталог OSG 2018 - 2019 - страница 1042

Навигация

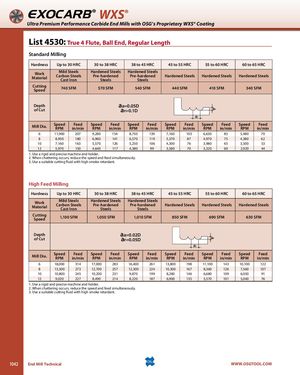

EXOCARB® WXS® Ultra Premium Performance Carbide End Mills with OSG’s Proprietary WXS® Coating List 4530: True 4 Flute, Ball End, Regular Length Standard Milling Hardness Up to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronHardened SteelsHardened SteelsPre-hardenedPre-hardenedHardened SteelsHardened SteelsHardened SteelsSteelsSteels CuttingSpeed 740 SFM 570 SFM 540 SFM 440 SFM 410 SFM 340 SFM Depth aa=0.05D of Cut ar=0.1D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 6 11,900 207 9,280 154 8,750 139 7,160 103 6,630 85 5,480 70 8 8,950 180 6,960 141 6,570 119 5,370 87 4,970 75 4,380 62 10 7,160 163 5,570 126 5,250 106 4,300 76 3,980 65 3,500 53 12 5,970 150 4,640 117 4,380 99 3,580 70 3,320 60 2,920 44 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Feed Milling Hardness Up to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC 55 to 60 HRC 60 to 65 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronHardened SteelsHardened SteelsPre-hardenedPre-hardenedHardened SteelsHardened SteelsHardened SteelsSteelsSteels CuttingSpeed 1,100 SFM 1,050 SFM 1,010 SFM 850 SFM 690 SFM 630 SFM Depth aa=0.02D of Cut ar=0.05D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 6 18,000 314 17,000 283 16,400 261 13,800 198 11,100 143 10,100 122 8 13,500 273 12,700 257 12,300 224 10,300 167 8,360 126 7,560 107 10 10,800 245 10,200 231 9,870 199 8,280 146 6,680 109 6,050 91 12 9,020 227 8,490 214 8,220 187 6,900 135 5,570 101 5,040 76 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. 1042 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta