Общий каталог OSG 2018 - 2019 - страница 1026

Навигация

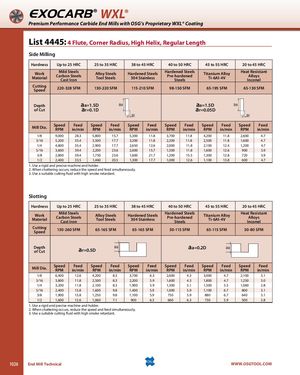

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 4445: 4 Flute, Corner Radius, High Helix, Regular Length Side Milling Hardness Up to 25 HRC 25 to 35 HRC 38 to 45 HRC 40 to 50 HRC 45 to 55 HRC 20 to 45 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool SteelsHardened Steels304 StainlessHardened SteelsPre-hardenedSteelsTitanium AlloyTi-6Al-4VHeat ResistantAlloysInconel CuttingSpeed 220-328 SFM 130-220 SFM 115-210 SFM 98-150 SFM 65-195 SFM 65-130 SFM Depthof Cut aa=1.5Dar=0.1D aa=1.5Dar=0.05D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 1/8 9,000 28.3 5,800 15.7 5,300 11.8 3,700 11.8 4,200 11.8 2,600 4.7 3/16 5,200 35.4 3,500 17.7 3,200 11.8 2,200 11.8 2,500 11.8 1,600 4.7 1/4 4,800 35.4 2,900 17.7 2,650 12.6 2,000 11.8 2,100 12.4 1,200 4.7 5/16 3,600 39.4 2,200 23.6 2,000 15.7 1,500 11.8 1,600 12.6 900 5.9 3/8 2,800 39.4 1,750 23.6 1,600 21.7 1,200 15.5 1,300 12.8 720 5.9 1/2 2,400 33.5 1,460 20.5 1,300 17.7 1,000 12.6 1,100 13.8 600 4.7 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. Slotting Hardness Up to 25 HRC 25 to 35 HRC 38 to 45 HRC 40 to 50 HRC 45 to 55 HRC 20 to 45 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool SteelsHardened Steels304 StainlessHardened SteelsPre-hardenedSteelsTitanium AlloyTi-6Al-4VHeat ResistantAlloysInconel CuttingSpeed 130-260 SFM 65-165 SFM 65-165 SFM 50-115 SFM 65-115 SFM 50-80 SFM Depthof Cut ar=0.5D aa=0.2D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 1/8 6,400 12.6 4,200 8.3 3,700 6.3 2,600 4.3 3,000 4.7 2,100 3.1 3/16 3,800 11.8 2,500 8.3 2,200 5.9 1,600 4.3 1,800 4.7 1,250 3.0 1/4 3,200 11.8 2,100 8.3 1,900 5.9 1,300 5.1 1,500 5.5 1,060 2.8 5/16 2,400 13.8 1,600 9.8 1,400 5.9 1,000 5.9 1,100 6.7 800 3.1 3/8 1,900 13.8 1,250 9.8 1,100 5.9 750 5.9 880 6.7 640 3.1 1/2 1,600 12.6 1,060 7.1 900 6.3 660 6.3 730 5.9 500 2.8 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. 1026 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta