Общий каталог OSG 2018 - 2019 - страница 1023

Навигация

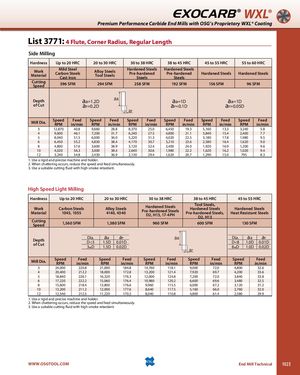

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3771: 4 Flute, Corner Radius, Regular Length Side Milling Hardness Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC 55 to 60 HRC WorkMaterial Mild SteelCarbon SteelsCast IronAlloy SteelsTool SteelsHardened Steels Hardened SteelsPre-hardenedPre-hardenedHardened SteelsHardened SteelsSteelsSteels CuttingSpeed 396 SFM 294 SFM 258 SFM 192 SFM 156 SFM 96 SFM Depth aa=1.2D aa=1D aa=1D of Cut ar=0.2D ar=0.1D ar=0.05D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/min 3 12,870 40.8 9,660 28.8 8,370 25.0 6,450 19.3 5,160 13.3 3,240 5.8 4 9,600 46.1 7,200 31.7 6,240 27.5 4,800 21.1 3,840 15.4 2,400 7.7 5 8,040 51.5 6,000 36.0 5,220 31.3 4,020 22.5 3,180 17.8 1,980 9.5 6 6,450 55.2 4,830 38.4 4,170 30.7 3,210 23.6 2,580 16.4 1,620 9.0 8 4,800 57.6 3,600 38.9 3,120 32.4 2,400 24.0 1,920 16.9 1,200 9.6 10 4,020 56.3 3,000 38.4 2,640 30.6 1,980 22.2 1,620 16.2 1,020 9.4 12 3,240 54.8 2,430 36.9 2,130 29.4 1,620 20.7 1,290 15.0 795 8.3 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. High Speed Light Milling Hardness Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC Work Carbon SteelsMaterial1045, 1055 Alloy Steels4140, 4340 Hardened SteelsPre-hardened SteelsD2, H13, 17-4PHTool Steels,Hardened SteelsPre-hardened Steels,D2, H13Hardened SteelsHeat Resistant Steels CuttingSpeed 1,560 SFM 1,380 SFM 960 SFM 600 SFM 130 SFM Depthof Cut Dia. aa arD<31.5D0.01D3≤D1.5D0.02D Dia. aa arD<81.0D0.01D8≤D1.0D0.02D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 3 24,000 220.8 21,000 184.8 14,760 118.1 9,000 72.0 4,800 32.6 4 20,400 212.2 18,000 172.8 13,200 121.4 7,920 69.7 4,200 33.6 5 18,840 226.1 16,320 176.3 12,000 124.8 7,200 72.0 3,840 33.8 6 17,220 222.2 15,060 176.4 10,980 120.2 6,600 69.6 3,480 32.5 8 15,600 218.4 13,800 176.6 9,960 115.5 6,000 67.2 3,120 31.2 10 13,200 211.2 12,000 177.6 8,640 117.5 5,160 66.0 2,760 32.0 12 12,540 212.5 11,220 170.2 8,040 110.8 4,800 61.4 2,580 29.9 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. WWW.OSGTOOL.COM End Mill Technical 1023

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta