Общий каталог OSG 2018 - 2019 - страница 1012

Навигация

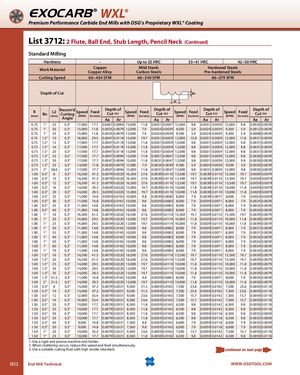

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3712: 2 Flute, Ball End, Stub Length, Pencil Neck (Continued) Standard Milling Hardness – Up to 32 HRC 33~41 HRC 42~50 HRC Work Material CopperCopper Alloy Mild SteelsCarbon Steels Hardened SteelsPre-hardened Steels Cutting Speed 66~464 SFM 66~340 SFM 66~279 SFM Depth of Cut R (mm) θn L2(mm)Recom’d Cutting Angle Speed (RPM) Feed(in/min)Depth ofCut (in)AaArSpeedFeed(RPM)(in/min)Depth ofCut (in)AaArSpeedFeed(RPM)(in/min)Depth ofCut (in)AaArSpeedFeed(RPM)(in/min)Depth ofCut (in)AaAr 0.75 1° 25 0.3° 17,000 17.7 0.0047 0.0094 15,000 11.8 0.0031 0.0047 12,000 9.8 0.0031 0.0039 12,000 9.8 0.0020 0.0039 0.75 1° 30 0.3° 13,000 11.8 0.0035 0.0079 12,000 7.9 0.0024 0.0039 9,500 5.9 0.0024 0.0039 9,500 5.9 0.0012 0.0039 0.75 1° 35 0.3° 13,000 11.8 0.0035 0.0079 12,000 7.9 0.0024 0.0039 9,500 5.9 0.0024 0.0039 9,500 5.9 0.0008 0.0039 0.75 1.5° 10 0.3° 18,000 29.5 0.0047 0.0118 15,000 19.7 0.0031 0.0059 12,000 13.8 0.0031 0.0059 12,000 11.8 0.0031 0.0059 0.75 1.5° 12 0.3° 17,000 17.7 0.0047 0.0118 15,000 11.8 0.0031 0.0059 12,000 9.8 0.0031 0.0059 12,000 9.8 0.0031 0.0059 0.75 1.5° 16 0.3° 17,000 17.7 0.0047 0.0118 15,000 11.8 0.0031 0.0059 12,000 9.8 0.0031 0.0059 12,000 9.8 0.0031 0.0059 0.75 1.5° 20 0.3° 17,000 17.7 0.0047 0.0118 15,000 11.8 0.0031 0.0059 12,000 9.8 0.0031 0.0059 12,000 9.8 0.0031 0.0059 0.75 1.5° 25 0.3° 17,000 17.7 0.0047 0.0094 15,000 11.8 0.0031 0.0047 12,000 9.8 0.0031 0.0039 12,000 9.8 0.0030 0.0039 0.75 1.5° 30 0.3° 17,000 17.7 0.0047 0.0094 15,000 11.8 0.0031 0.0047 12,000 9.8 0.0031 0.0039 12,000 9.8 0.0030 0.0039 0.75 1.5° 35 0.3° 13,000 11.8 0.0030 0.0079 12,000 7.9 0.0024 0.0039 9,500 5.9 0.0024 0.0039 9,500 5.9 0.0020 0.0039 0.75 2° 38.6 0.3° 17,000 17.7 0.0047 0.0094 15,000 11.8 0.0031 0.0047 12,000 9.8 0.0031 0.0039 12,000 9.8 0.0030 0.0039 1.00 0.5° 8 0.3° 16,500 41.3 0.0079 0.0220 16,500 27.6 0.0039 0.0110 13,500 19.7 0.0039 0.0110 13,500 19.7 0.0039 0.0079 1.00 0.5° 10 0.3° 16,500 41.3 0.0079 0.0220 16,500 27.6 0.0039 0.0110 13,500 19.7 0.0039 0.0110 13,500 19.7 0.0039 0.0079 1.00 0.5° 12 0.3° 16,500 41.3 0.0079 0.0220 16,500 27.6 0.0039 0.0110 13,500 19.7 0.0039 0.0110 13,500 19.7 0.0039 0.0079 1.00 0.5° 16 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 0.5° 20 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 0.5° 25 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 0.5° 30 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 0.5° 35 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 0.5° 40 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 1° 16 0.3° 16,500 41.3 0.0079 0.0220 16,500 27.6 0.0039 0.0110 13,500 19.7 0.0039 0.0110 13,500 19.7 0.0039 0.0079 1.00 1° 20 0.3° 14,000 29.5 0.0079 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 1° 25 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 1° 30 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0031 0.0039 1.00 1° 35 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0031 0.0039 1.00 1° 40 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 1° 50 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 1° 60 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 1° 70 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 1.5° 16 0.3° 16,500 41.3 0.0079 0.0220 16,500 27.6 0.0039 0.0110 13,500 19.7 0.0039 0.0110 13,500 19.7 0.0039 0.0079 1.00 1.5° 20 0.3° 16,500 41.3 0.0079 0.0220 16,500 27.6 0.0039 0.0110 13,500 19.7 0.0039 0.0110 13,500 19.7 0.0039 0.0079 1.00 1.5° 25 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 1.5° 30 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 1.5° 35 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.00 1.5° 41.5 0.3° 11,000 14.8 0.0059 0.0165 10,000 9.8 0.0039 0.0083 8,000 7.9 0.0039 0.0071 8,000 7.9 0.0024 0.0039 1.00 2° 31.5 0.3° 14,000 29.5 0.0059 0.0220 13,000 19.7 0.0039 0.0110 10,000 11.8 0.0039 0.0110 10,000 11.8 0.0039 0.0079 1.50 0.5° 8 0.3° 15,000 47.2 0.0079 0.0331 9,500 31.5 0.0059 0.0165 7,500 23.6 0.0059 0.0165 7,500 23.6 0.0059 0.0118 1.50 0.5° 10 0.3° 15,000 47.2 0.0079 0.0331 9,500 31.5 0.0059 0.0165 7,500 23.6 0.0059 0.0165 7,500 23.6 0.0059 0.0118 1.50 0.5° 12 0.3° 12,000 35.4 0.0079 0.0331 9,500 23.6 0.0059 0.0165 7,500 15.7 0.0059 0.0142 7,500 15.7 0.0059 0.0118 1.50 0.5° 16 0.3° 10,000 35.4 0.0079 0.0331 9,500 23.6 0.0059 0.0165 7,500 15.7 0.0059 0.0142 7,500 15.7 0.0059 0.0118 1.50 0.5° 20 0.3° 10,000 17.7 0.0079 0.0331 8,500 11.8 0.0059 0.0165 6,500 9.8 0.0059 0.0142 6,500 9.8 0.0059 0.0118 1.50 0.5° 25 0.3° 10,000 17.7 0.0079 0.0331 8,500 11.8 0.0059 0.0165 6,500 9.8 0.0059 0.0142 6,500 9.8 0.0059 0.0118 1.50 0.5° 30 0.3° 10,000 17.7 0.0079 0.0331 8,500 11.8 0.0059 0.0165 6,500 9.8 0.0059 0.0118 6,500 9.8 0.0035 0.0059 1.50 0.5° 35 0.3° 10,000 17.7 0.0079 0.0331 8,500 11.8 0.0059 0.0165 6,500 9.8 0.0059 0.0118 6,500 9.8 0.0035 0.0059 1.50 0.5° 40 0.3° 9,000 14.8 0.0079 0.0331 7,500 9.8 0.0059 0.0165 6,000 7.9 0.0059 0.0118 6,000 7.9 0.0035 0.0059 1.50 0.5° 50 0.3° 9,000 14.8 0.0079 0.0331 7,500 9.8 0.0059 0.0165 6,000 7.9 0.0059 0.0118 6,000 7.9 0.0035 0.0059 1.50 1° 20 0.3° 10,000 35.4 0.0079 0.0331 9,500 23.6 0.0059 0.0165 7,500 15.7 0.0059 0.0142 7,500 15.7 0.0059 0.0118 1.50 1° 25 0.3° 10,000 17.7 0.0079 0.0331 8,500 11.8 0.0059 0.0165 6,500 9.8 0.0059 0.0142 6,500 9.8 0.0059 0.0118 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. 1012 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta