Общий каталог OSG 2018 - 2019 - страница 1003

Навигация

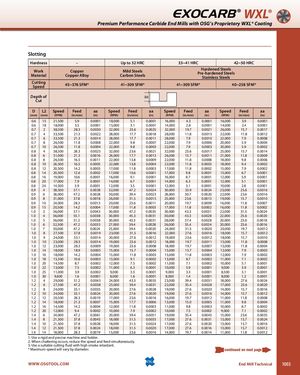

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating Slotting Hardness – Up to 32 HRC 33~41 HRC 42~50 HRC Work Copper Mild SteelsMaterialCopper AlloyCarbon Steels Hardened SteelsPre-hardened SteelsStainless Steels CuttingSpeed 45~376 SFM* 41~309 SFM* 41~309 SFM* 40~258 SFM* Depth of Cut D L2 Speed Feed aa Speed Feed aa Speed Feed aa Speed Feed aa (mm) (mm) (RPM) (in/min) (in) (RPM) (in/min) (in) (RPM) (in/min) (in) (RPM) (in/min) (in) 0.6 15 21,500 5.9 0.0001 18,000 5.1 0.0001 16,000 4.3 0.0001 16,000 3.9 0.0001 0.6 18 18,000 3.5 0.0001 15,000 3.1 0.0001 14,000 2.8 0.0001 14,000 2.4 0.0001 0.7 2 38,500 28.3 0.0030 32,000 23.6 0.0025 32,000 19.7 0.0021 26,000 15.7 0.0017 0.7 4 33,500 21.3 0.0022 28,000 17.7 0.0018 28,000 11.8 0.0015 22,000 11.8 0.0012 0.7 6 33,500 21.3 0.0014 28,000 17.7 0.0011 28,000 7.9 0.0010 22,000 7.9 0.0008 0.7 8 26,500 11.8 0.0008 22,000 9.8 0.0007 22,000 7.9 0.0006 20,000 5.9 0.0004 0.7 10 26,500 11.8 0.0004 22,000 9.8 0.0003 22,000 7.9 0.0003 20,000 5.9 0.0002 0.8 4 38,500 28.3 0.0025 32,000 23.6 0.0021 32,000 23.6 0.0017 25,000 15.7 0.0014 0.8 6 31,000 21.3 0.0016 26,000 17.7 0.0013 26,000 15.7 0.0011 21,000 11.8 0.0009 0.8 8 26,500 16.5 0.0011 22,000 13.8 0.0009 22,000 11.8 0.0008 18,000 9.8 0.0006 0.8 10 26,500 16.5 0.0005 22,000 13.8 0.0004 22,000 11.8 0.0003 18,000 9.4 0.0002 0.8 12 20,500 14.2 0.0003 17,000 11.8 0.0003 17,000 11.8 0.0002 15,000 7.9 0.0002 0.8 14 20,500 12.6 0.0002 17,000 10.6 0.0001 17,000 9.8 0.0001 13,000 6.7 0.0001 0.8 16 19,000 10.6 0.0001 16,000 9.1 0.0001 16,000 8.7 0.0001 12,000 5.9 0.0001 0.8 20 17,000 7.9 0.0001 14,000 6.7 0.0001 14,000 6.3 0.0001 12,000 5.1 0.0001 0.8 24 14,500 3.9 0.0001 12,000 3.5 0.0001 12,000 3.1 0.0001 10,000 2.8 0.0001 0.9 4 38,500 57.1 0.0028 32,000 47.2 0.0024 30,000 33.9 0.0024 23,000 25.6 0.0016 0.9 6 36,000 47.2 0.0028 30,000 39.4 0.0023 28,000 30.7 0.0020 22,000 23.6 0.0016 0.9 8 31,000 37.8 0.0018 26,000 31.5 0.0015 25,000 23.6 0.0013 19,000 15.7 0.0010 0.9 10 24,000 28.3 0.0013 20,000 23.6 0.0011 20,000 19.7 0.0009 16,000 11.8 0.0007 0.9 15 20,500 14.2 0.0004 17,000 11.8 0.0003 17,000 11.8 0.0002 16,000 11.8 0.0002 1.0 3 36,000 57.1 0.0043 30,000 47.2 0.0035 30,000 43.3 0.0031 22,000 31.5 0.0024 1.0 4 36,000 55.1 0.0038 30,000 45.3 0.0031 30,000 43.3 0.0028 22,000 25.6 0.0020 1.0 5 36,000 51.2 0.0038 30,000 43.3 0.0031 28,000 37.4 0.0028 20,000 23.6 0.0018 1.0 6 32,500 47.2 0.0033 27,000 39.4 0.0028 26,000 35.4 0.0024 20,000 23.6 0.0016 1.0 7 30,000 47.2 0.0024 25,000 39.4 0.0020 24,000 31.5 0.0020 20,000 19.7 0.0012 1.0 8 27,500 37.8 0.0019 23,000 31.5 0.0016 22,000 27.6 0.0016 18,000 15.7 0.0012 1.0 9 24,000 33.1 0.0014 20,000 27.6 0.0012 19,000 23.6 0.0012 18,000 15.7 0.0010 1.0 10 23,000 28.3 0.0014 19,000 23.6 0.0012 18,000 19.7 0.0011 15,000 11.8 0.0008 1.0 12 23,000 28.3 0.0009 19,000 23.6 0.0008 18,000 19.7 0.0007 15,000 11.8 0.0004 1.0 14 18,000 18.9 0.0005 15,000 15.7 0.0004 15,000 15.7 0.0004 12,000 7.9 0.0003 1.0 16 18,000 14.2 0.0004 15,000 11.8 0.0003 15,000 11.8 0.0003 12,000 7.9 0.0002 1.0 18 15,500 10.6 0.0003 13,000 9.1 0.0002 13,000 8.7 0.0002 11,000 7.1 0.0002 1.0 20 14,500 8.7 0.0002 12,000 7.5 0.0002 11,000 7.1 0.0002 10,000 5.1 0.0001 1.0 22 13,000 7.5 0.0002 11,000 6.3 0.0001 10,000 5.9 0.0001 9,000 3.9 0.0001 1.0 25 11,000 3.9 0.0002 9,000 3.5 0.0001 9,000 3.3 0.0001 8,500 3.1 0.0001 1.0 30 9,600 1.6 0.0001 8,000 1.6 0.0001 8,000 1.4 0.0001 8,000 1.2 0.0001 1.2 4 29,000 51.2 0.0043 24,000 43.3 0.0035 23,000 39.4 0.0031 18,000 27.6 0.0024 1.2 6 27,500 47.2 0.0038 23,000 39.4 0.0031 22,000 35.4 0.0028 17,000 23.6 0.0020 1.2 8 24,000 33.1 0.0033 20,000 27.6 0.0028 19,000 27.6 0.0020 14,000 15.7 0.0016 1.2 10 24,000 33.1 0.0024 20,000 27.6 0.0020 19,000 27.6 0.0016 14,000 15.7 0.0012 1.2 12 20,500 28.3 0.0019 17,000 23.6 0.0016 16,000 19.7 0.0012 11,000 11.8 0.0008 1.2 14 18,000 21.3 0.0007 15,000 17.7 0.0006 13,000 15.0 0.0005 11,000 9.8 0.0004 1.2 16 14,500 14.2 0.0004 12,000 11.8 0.0003 11,000 9.8 0.0003 10,000 8.7 0.0002 1.2 20 12,000 9.4 0.0002 10,000 7.9 0.0002 10,000 7.5 0.0002 9,000 7.1 0.0002 1.4 6 24,000 47.2 0.0061 20,000 39.4 0.0051 19,000 35.4 0.0043 15,000 23.6 0.0035 1.4 8 21,500 37.8 0.0043 18,000 31.5 0.0035 17,000 27.6 0.0031 13,000 15.7 0.0024 1.4 10 21,500 37.8 0.0028 18,000 31.5 0.0024 17,000 27.6 0.0020 13,000 15.7 0.0016 1.4 12 21,500 37.8 0.0024 18,000 31.5 0.0020 17,000 27.6 0.0016 13,000 15.7 0.0012 1.4 14 18,000 28.3 0.0019 15,000 23.6 0.0016 14,000 19.7 0.0014 11,000 11.8 0.0012 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. * Maximum speed will vary by diameter. WWW.OSGTOOL.COM End Mill Technical 1003

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta