Общий каталог Osawa 2018 - страница 422

Навигация

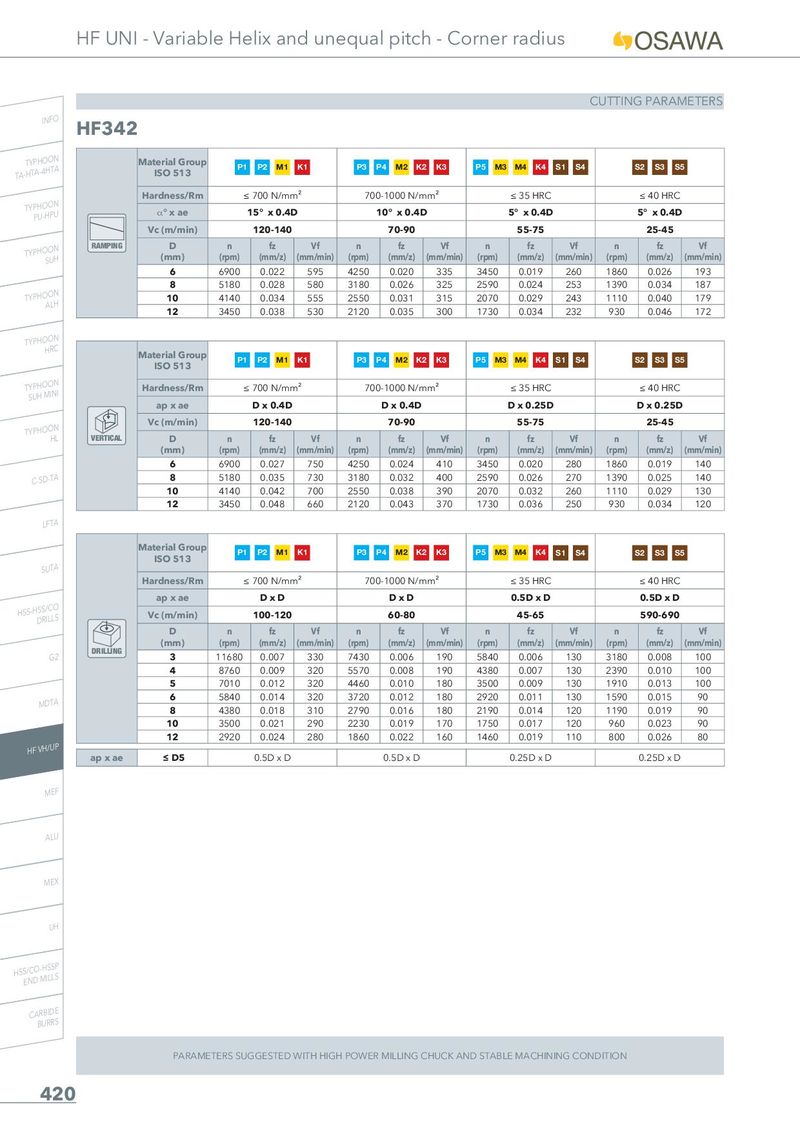

HF UNI - Variable Helix and unequal pitch - Corner radius CUTTING PARAMETERS INFO HF342 TA-THYTPAH-4OHOTNA Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TYPPHUO-HOPNU _° x ae 15° x 0.4D 10° x 0.4D 5° x 0.4D 5° x 0.4D Vc (m/min) 120-140 70-90 55-75 25-45 TYPHOSOUNH RAMPING D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 6 6900 0.022 595 4250 0.020 335 3450 0.019 260 1860 0.026 193 8 5180 0.028 580 3180 0.026 325 2590 0.024 253 1390 0.034 187 TYPHOAOLNH 10 4140 0.034 555 2550 0.031 315 2070 0.029 243 1110 0.040 179 12 3450 0.038 530 2120 0.035 300 1730 0.034 232 930 0.046 172 TYPHOHORNC Material Group ISO 513 P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TSYUPHHOMOINNI Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D TYPHOOHNL Vc (m/min) 120-140 70-90 55-75 25-45 VERTICAL D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 6 6900 0.027 750 4250 0.024 410 3450 0.020 280 1860 0.019 140 C-SD-TA 8 5180 0.035 730 3180 0.032 400 2590 0.026 270 1390 0.025 140 10 4140 0.042 700 2550 0.038 390 2070 0.032 260 1110 0.029 130 12 3450 0.048 660 2120 0.043 370 1730 0.036 250 930 0.034 120 LFTA Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 SUTA Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae DxD DxD 0.5D x D 0.5D x D HSS-HDSSR/ILCLOS Vc (m/min) 100-120 60-80 45-65 590-690 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) G2 DRILLING 3 11680 0.007 330 7430 0.006 190 5840 0.006 130 3180 0.008 100 4 8760 0.009 320 5570 0.008 190 4380 0.007 130 2390 0.010 100 5 7010 0.012 320 4460 0.010 180 3500 0.009 130 1910 0.013 100 MDTA 6 5840 0.014 320 3720 0.012 180 2920 0.011 130 1590 0.015 90 8 4380 0.018 310 2790 0.016 180 2190 0.014 120 1190 0.019 90 10 3500 0.021 290 2230 0.019 170 1750 0.017 120 960 0.023 90 12 2920 0.024 280 1860 0.022 160 1460 0.019 110 800 0.026 80 HF VH/UP ap x ae ≤ D5 0.5D x D 0.5D x D 0.25D x D 0.25D x D MEF ALU MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION 420

Общий каталог Osawa 2021

Общий каталог Osawa 2021