Общий каталог Osawa 2018 - страница 42

Навигация

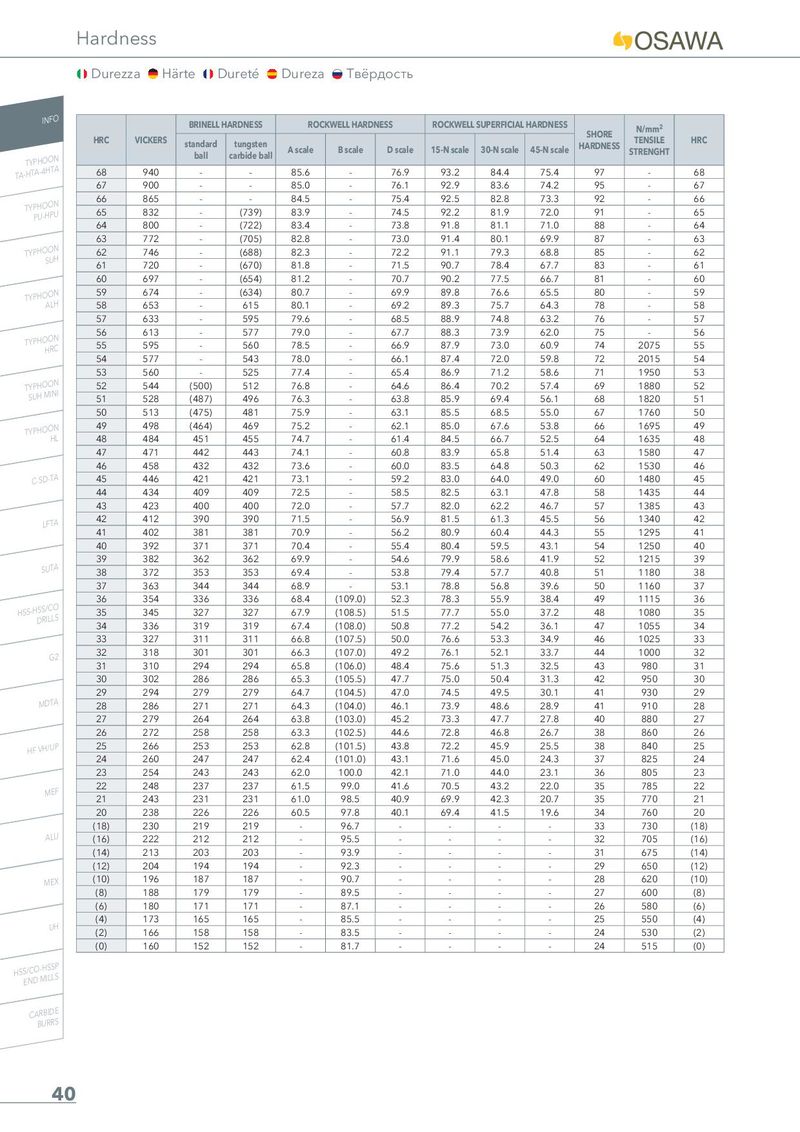

Hardness Durezza Härte Dureté Dureza Твёрдость INFO BRINELL HARDNESS ROCKWELL HARDNESS ROCKWELL SUPERFICIAL HARDNESS N/mm2 HRC VICKERS SHORE TENSILE HRC standard tungsten A scale B scale D scale 15-N scale 30-N scale 45-N scale HARDNESS STRENGHT TA-THYTPAH-4OHOTNA ball carbide ball 68 940 - - 85.6 - 76.9 93.2 84.4 75.4 97 - 68 67 900 - - 85.0 - 76.1 92.9 83.6 74.2 95 - 67 TYPPHUO-HOPNU 66 865 - - 84.5 - 75.4 92.5 82.8 73.3 92 - 66 65 832 - (739) 83.9 - 74.5 92.2 81.9 72.0 91 - 65 64 800 - (722) 83.4 - 73.8 91.8 81.1 71.0 88 - 64 63 772 - (705) 82.8 - 73.0 91.4 80.1 69.9 87 - 63 TYPHOSOUNH 62 746 - (688) 82.3 - 72.2 91.1 79.3 68.8 85 - 62 61 720 - (670) 81.8 - 71.5 90.7 78.4 67.7 83 - 61 60 697 - (654) 81.2 - 70.7 90.2 77.5 66.7 81 - 60 TYPHOAOLNH 59 674 - (634) 80.7 - 69.9 89.8 76.6 65.5 80 - 59 58 653 - 615 80.1 - 69.2 89.3 75.7 64.3 78 - 58 57 633 - 595 79.6 - 68.5 88.9 74.8 63.2 76 - 57 TYPHOHORNC 56 613 - 577 79.0 - 67.7 88.3 73.9 62.0 75 - 56 55 595 - 560 78.5 - 66.9 87.9 73.0 60.9 74 2075 55 54 577 - 543 78.0 - 66.1 87.4 72.0 59.8 72 2015 54 53 560 - 525 77.4 - 65.4 86.9 71.2 58.6 71 1950 53 TSYUPHHOMOINNI 52 544 (500) 512 76.8 - 64.6 86.4 70.2 57.4 69 1880 52 51 528 (487) 496 76.3 - 63.8 85.9 69.4 56.1 68 1820 51 50 513 (475) 481 75.9 - 63.1 85.5 68.5 55.0 67 1760 50 TYPHOOHNL 49 498 (464) 469 75.2 - 62.1 85.0 67.6 53.8 66 1695 49 48 484 451 455 74.7 - 61.4 84.5 66.7 52.5 64 1635 48 47 471 442 443 74.1 - 60.8 83.9 65.8 51.4 63 1580 47 46 458 432 432 73.6 - 60.0 83.5 64.8 50.3 62 1530 46 C-SD-TA 45 446 421 421 73.1 - 59.2 83.0 64.0 49.0 60 1480 45 44 434 409 409 72.5 - 58.5 82.5 63.1 47.8 58 1435 44 43 423 400 400 72.0 - 57.7 82.0 62.2 46.7 57 1385 43 LFTA 42 412 390 390 71.5 - 56.9 81.5 61.3 45.5 56 1340 42 41 402 381 381 70.9 - 56.2 80.9 60.4 44.3 55 1295 41 40 392 371 371 70.4 - 55.4 80.4 59.5 43.1 54 1250 40 39 382 362 362 69.9 - 54.6 79.9 58.6 41.9 52 1215 39 SUTA 38 372 353 353 69.4 - 53.8 79.4 57.7 40.8 51 1180 38 37 363 344 344 68.9 - 53.1 78.8 56.8 39.6 50 1160 37 HSS-HDSSR/ILCLOS 36 354 336 336 68.4 (109.0) 52.3 78.3 55.9 38.4 49 1115 36 35 345 327 327 67.9 (108.5) 51.5 77.7 55.0 37.2 48 1080 35 34 336 319 319 67.4 (108.0) 50.8 77.2 54.2 36.1 47 1055 34 33 327 311 311 66.8 (107.5) 50.0 76.6 53.3 34.9 46 1025 33 G2 32 318 301 301 66.3 (107.0) 49.2 76.1 52.1 33.7 44 1000 32 31 310 294 294 65.8 (106.0) 48.4 75.6 51.3 32.5 43 980 31 30 302 286 286 65.3 (105.5) 47.7 75.0 50.4 31.3 42 950 30 29 294 279 279 64.7 (104.5) 47.0 74.5 49.5 30.1 41 930 29 MDTA 28 286 271 271 64.3 (104.0) 46.1 73.9 48.6 28.9 41 910 28 27 279 264 264 63.8 (103.0) 45.2 73.3 47.7 27.8 40 880 27 26 272 258 258 63.3 (102.5) 44.6 72.8 46.8 26.7 38 860 26 HF VH/UP 25 266 253 253 62.8 (101.5) 43.8 72.2 45.9 25.5 38 840 25 24 260 247 247 62.4 (101.0) 43.1 71.6 45.0 24.3 37 825 24 23 254 243 243 62.0 100.0 42.1 71.0 44.0 23.1 36 805 23 MEF 22 248 237 237 61.5 99.0 41.6 70.5 43.2 22.0 35 785 22 21 243 231 231 61.0 98.5 40.9 69.9 42.3 20.7 35 770 21 20 238 226 226 60.5 97.8 40.1 69.4 41.5 19.6 34 760 20 (18) 230 219 219 - 96.7 - - - - 33 730 (18) ALU (16) 222 212 212 - 95.5 - - - - 32 705 (16) (14) 213 203 203 - 93.9 - - - - 31 675 (14) (12) 204 194 194 - 92.3 - - - - 29 650 (12) MEX (10) 196 187 187 - 90.7 - - - - 28 620 (10) (8) 188 179 179 - 89.5 - - - - 27 600 (8) (6) 180 171 171 - 87.1 - - - - 26 580 (6) UH (4) 173 165 165 - 85.5 - - - - 25 550 (4) (2) 166 158 158 - 83.5 - - - - 24 530 (2) (0) 160 152 152 - 81.7 - - - - 24 515 (0) HSSE/NCDO-MHISLSLPS CARBIDE BURRS 40

Общий каталог Osawa 2021

Общий каталог Osawa 2021