Общий каталог Osawa 2018 - страница 403

Навигация

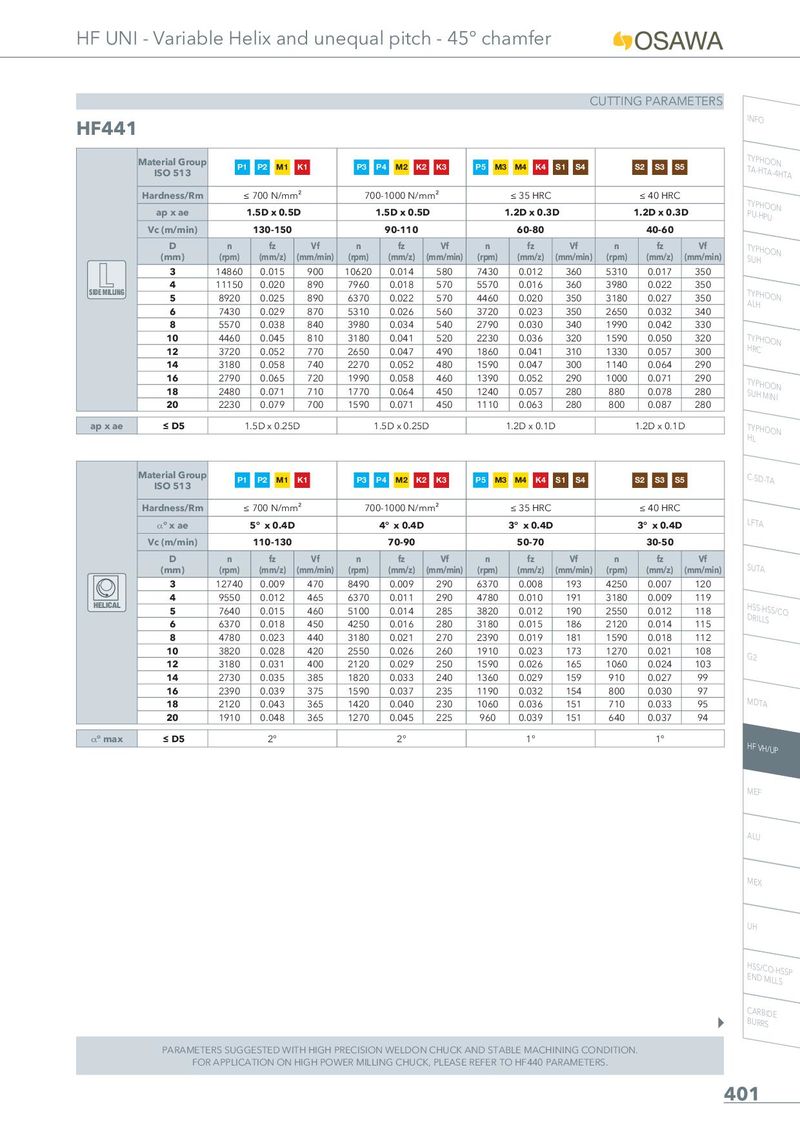

HF UNI - Variable Helix and unequal pitch - 45° chamfer CUTTING PARAMETERS HF441 INFO Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TPYUP-HHPOUON ap x ae 1.5D x 0.5D 1.5D x 0.5D 1.2D x 0.3D 1.2D x 0.3D Vc (m/min) 130-150 90-110 60-80 40-60 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 3 14860 0.015 900 10620 0.014 580 7430 0.012 360 5310 0.017 350 SIDE MILLING 4 11150 0.020 890 7960 0.018 570 5570 0.016 360 3980 0.022 350 TAYLPHHOON 5 8920 0.025 890 6370 0.022 570 4460 0.020 350 3180 0.027 350 6 7430 0.029 870 5310 0.026 560 3720 0.023 350 2650 0.032 340 8 5570 0.038 840 3980 0.034 540 2790 0.030 340 1990 0.042 330 10 4460 0.045 810 3180 0.041 520 2230 0.036 320 1590 0.050 320 THYRPCHOON 12 3720 0.052 770 2650 0.047 490 1860 0.041 310 1330 0.057 300 14 3180 0.058 740 2270 0.052 480 1590 0.047 300 1140 0.064 290 16 2790 0.065 720 1990 0.058 460 1390 0.052 290 1000 0.071 290 TSUYPHHMOIONIN 18 2480 0.071 710 1770 0.064 450 1240 0.057 280 880 0.078 280 20 2230 0.079 700 1590 0.071 450 1110 0.063 280 800 0.087 280 ap x ae ≤ D5 1.5D x 0.25D 1.5D x 0.25D 1.2D x 0.1D 1.2D x 0.1D THYLPHOON Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 C-SD-TA ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC _° x ae 5° x 0.4D 4° x 0.4D 3° x 0.4D 3° x 0.4D LFTA Vc (m/min) 110-130 70-90 50-70 30-50 D n fz Vf n fz Vf n fz Vf n fz Vf SUTA (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 3 12740 0.009 470 8490 0.009 290 6370 0.008 193 4250 0.007 120 HELICAL 4 9550 0.012 465 6370 0.011 290 4780 0.010 191 3180 0.009 119 5 7640 0.015 460 5100 0.014 285 3820 0.012 190 2550 0.012 118 HDSRSIL-LHSSS/CO 6 6370 0.018 450 4250 0.016 280 3180 0.015 186 2120 0.014 115 8 4780 0.023 440 3180 0.021 270 2390 0.019 181 1590 0.018 112 10 3820 0.028 420 2550 0.026 260 1910 0.023 173 1270 0.021 108 G2 12 3180 0.031 400 2120 0.029 250 1590 0.026 165 1060 0.024 103 14 2730 0.035 385 1820 0.033 240 1360 0.029 159 910 0.027 99 16 2390 0.039 375 1590 0.037 235 1190 0.032 154 800 0.030 97 18 2120 0.043 365 1420 0.040 230 1060 0.036 151 710 0.033 95 MDTA 20 1910 0.048 365 1270 0.045 225 960 0.039 151 640 0.037 94 _° max ≤ D5 2° 2° 1° 1° HF VH/UP MEF ALU MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE PARAMETERS SUGGESTED WITH HIGH PRECISION WELDON CHUCK AND STABLE MACHINING CONDITION. FOR APPLICATION ON HIGH POWER MILLING CHUCK, PLEASE REFER TO HF440 PARAMETERS. 401

Общий каталог Osawa 2021

Общий каталог Osawa 2021