Общий каталог Osawa 2018 - страница 321

Навигация

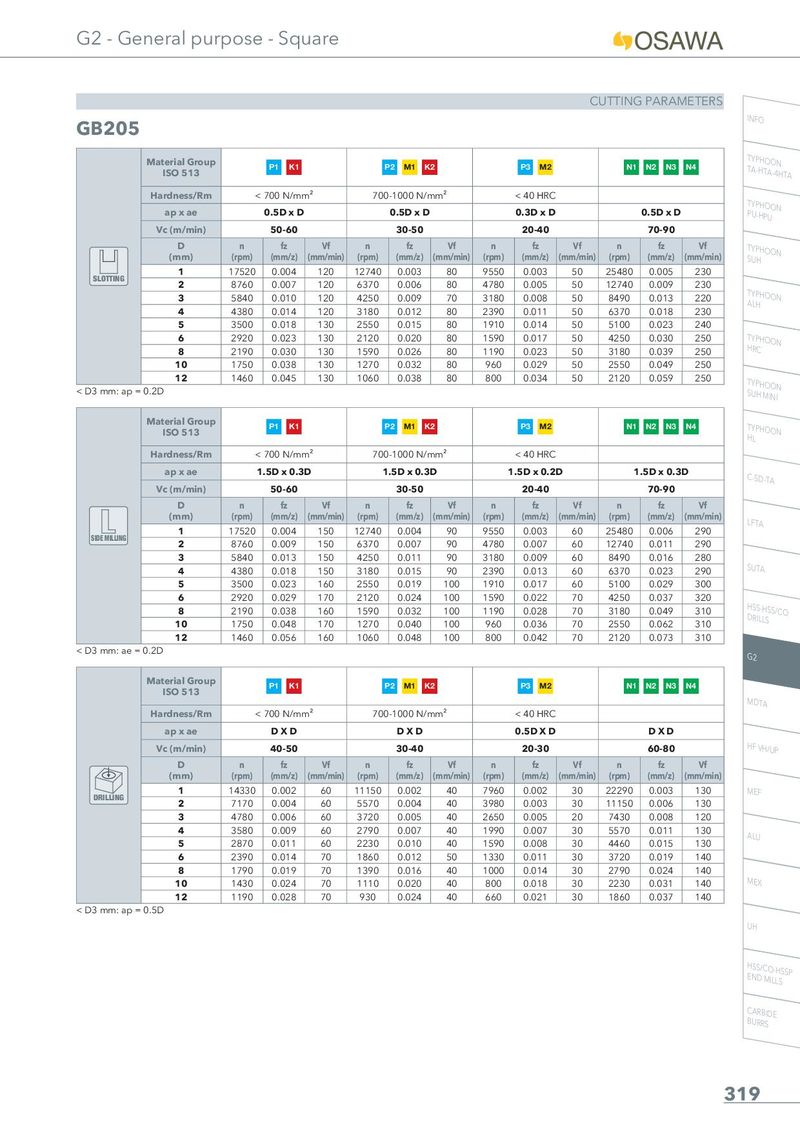

G2 - General purpose - Square CUTTING PARAMETERS GB205 INFO Material Group P1 K1 P2 M1 K2 P3 M2 N1 N2 N3 N4 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 40 HRC TPYUP-HHPOUON ap x ae 0.5D x D 0.5D x D 0.3D x D 0.5D x D Vc (m/min) 50-60 30-50 20-40 70-90 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SLOTTING 1 17520 0.004 120 12740 0.003 80 9550 0.003 50 25480 0.005 230 2 8760 0.007 120 6370 0.006 80 4780 0.005 50 12740 0.009 230 TAYLPHHOON 3 5840 0.010 120 4250 0.009 70 3180 0.008 50 8490 0.013 220 4 4380 0.014 120 3180 0.012 80 2390 0.011 50 6370 0.018 230 5 3500 0.018 130 2550 0.015 80 1910 0.014 50 5100 0.023 240 6 2920 0.023 130 2120 0.020 80 1590 0.017 50 4250 0.030 250 THYRPCHOON 8 2190 0.030 130 1590 0.026 80 1190 0.023 50 3180 0.039 250 10 1750 0.038 130 1270 0.032 80 960 0.029 50 2550 0.049 250 12 1460 0.045 130 1060 0.038 80 800 0.034 50 2120 0.059 250 TSUYPHHMOIONIN < D3 mm: ap = 0.2D Material Group P1 K1 P2 M1 K2 P3 M2 N1 N2 N3 N4 THYLPHOON ISO 513 Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 40 HRC ap x ae 1.5D x 0.3D 1.5D x 0.3D 1.5D x 0.2D 1.5D x 0.3D C-SD-TA Vc (m/min) 50-60 30-50 20-40 70-90 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) LFTA SIDE MILLING 1 17520 0.004 150 12740 0.004 90 9550 0.003 60 25480 0.006 290 2 8760 0.009 150 6370 0.007 90 4780 0.007 60 12740 0.011 290 3 5840 0.013 150 4250 0.011 90 3180 0.009 60 8490 0.016 280 4 4380 0.018 150 3180 0.015 90 2390 0.013 60 6370 0.023 290 SUTA 5 3500 0.023 160 2550 0.019 100 1910 0.017 60 5100 0.029 300 6 2920 0.029 170 2120 0.024 100 1590 0.022 70 4250 0.037 320 8 2190 0.038 160 1590 0.032 100 1190 0.028 70 3180 0.049 310 HDSRSIL-LHSSS/CO 10 1750 0.048 170 1270 0.040 100 960 0.036 70 2550 0.062 310 12 1460 0.056 160 1060 0.048 100 800 0.042 70 2120 0.073 310 < D3 mm: ae = 0.2D G2 Material Group P1 K1 P2 M1 K2 P3 M2 N1 N2 N3 N4 ISO 513 MDTA Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 40 HRC ap x ae DXD DXD 0.5D X D DXD Vc (m/min) 40-50 30-40 20-30 60-80 HF VH/UP D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) DRILLING 1 14330 0.002 60 11150 0.002 40 7960 0.002 30 22290 0.003 130 MEF 2 7170 0.004 60 5570 0.004 40 3980 0.003 30 11150 0.006 130 3 4780 0.006 60 3720 0.005 40 2650 0.005 20 7430 0.008 120 4 3580 0.009 60 2790 0.007 40 1990 0.007 30 5570 0.011 130 ALU 5 2870 0.011 60 2230 0.010 40 1590 0.008 30 4460 0.015 130 6 2390 0.014 70 1860 0.012 50 1330 0.011 30 3720 0.019 140 8 1790 0.019 70 1390 0.016 40 1000 0.014 30 2790 0.024 140 10 1430 0.024 70 1110 0.020 40 800 0.018 30 2230 0.031 140 MEX 12 1190 0.028 70 930 0.024 40 660 0.021 30 1860 0.037 140 < D3 mm: ap = 0.5D UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 319

Общий каталог Osawa 2021

Общий каталог Osawa 2021