Общий каталог Osawa 2018 - страница 155

Навигация

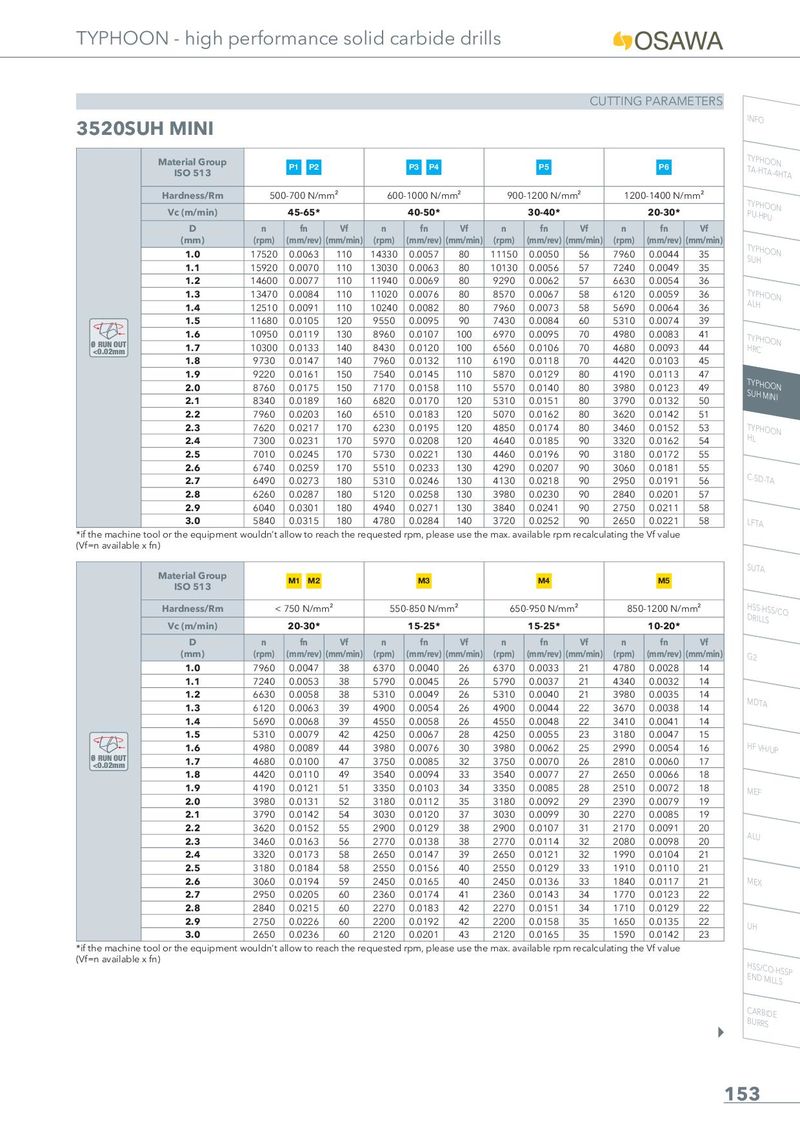

TYPHOON - high performance solid carbide drills CUTTING PARAMETERS 3520SUH MINI INFO Material Group P1 P2 P3 P4 P5 P6 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm 500-700 N/mm² 600-1000 N/mm² 900-1200 N/mm² 1200-1400 N/mm² TPYUP-HHPOUON Vc (m/min) 45-65* 40-50* 30-40* 20-30* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) TSUYPHHOON 1.0 17520 0.0063 110 14330 0.0057 80 11150 0.0050 56 7960 0.0044 35 1.1 15920 0.0070 110 13030 0.0063 80 10130 0.0056 57 7240 0.0049 35 1.2 14600 0.0077 110 11940 0.0069 80 9290 0.0062 57 6630 0.0054 36 1.3 13470 0.0084 110 11020 0.0076 80 8570 0.0067 58 6120 0.0059 36 TAYLPHHOON 1.4 12510 0.0091 110 10240 0.0082 80 7960 0.0073 58 5690 0.0064 36 1.5 11680 0.0105 120 9550 0.0095 90 7430 0.0084 60 5310 0.0074 39 1.6 10950 0.0119 130 8960 0.0107 100 6970 0.0095 70 4980 0.0083 41 THYRPCHOON Ø RUN OUT 1.7 10300 0.0133 140 8430 0.0120 100 6560 0.0106 70 4680 0.0093 44 <0.02mm 1.8 9730 0.0147 140 7960 0.0132 110 6190 0.0118 70 4420 0.0103 45 1.9 9220 0.0161 150 7540 0.0145 110 5870 0.0129 80 4190 0.0113 47 TSUYPHHMOIONIN 2.0 8760 0.0175 150 7170 0.0158 110 5570 0.0140 80 3980 0.0123 49 2.1 8340 0.0189 160 6820 0.0170 120 5310 0.0151 80 3790 0.0132 50 2.2 7960 0.0203 160 6510 0.0183 120 5070 0.0162 80 3620 0.0142 51 2.3 7620 0.0217 170 6230 0.0195 120 4850 0.0174 80 3460 0.0152 53 THYLPHOON 2.4 7300 0.0231 170 5970 0.0208 120 4640 0.0185 90 3320 0.0162 54 2.5 7010 0.0245 170 5730 0.0221 130 4460 0.0196 90 3180 0.0172 55 2.6 6740 0.0259 170 5510 0.0233 130 4290 0.0207 90 3060 0.0181 55 2.7 6490 0.0273 180 5310 0.0246 130 4130 0.0218 90 2950 0.0191 56 C-SD-TA 2.8 6260 0.0287 180 5120 0.0258 130 3980 0.0230 90 2840 0.0201 57 2.9 6040 0.0301 180 4940 0.0271 130 3840 0.0241 90 2750 0.0211 58 3.0 5840 0.0315 180 4780 0.0284 140 3720 0.0252 90 2650 0.0221 58 LFTA *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) Material Group SUTA ISO 513 M1 M2 M3 M4 M5 Hardness/Rm < 750 N/mm² 550-850 N/mm² 650-950 N/mm² 850-1200 N/mm² HDSRSIL-LHSSS/CO Vc (m/min) 20-30* 15-25* 15-25* 10-20* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) G2 1.0 7960 0.0047 38 6370 0.0040 26 6370 0.0033 21 4780 0.0028 14 1.1 7240 0.0053 38 5790 0.0045 26 5790 0.0037 21 4340 0.0032 14 1.2 6630 0.0058 38 5310 0.0049 26 5310 0.0040 21 3980 0.0035 14 MDTA 1.3 6120 0.0063 39 4900 0.0054 26 4900 0.0044 22 3670 0.0038 14 1.4 5690 0.0068 39 4550 0.0058 26 4550 0.0048 22 3410 0.0041 14 1.5 5310 0.0079 42 4250 0.0067 28 4250 0.0055 23 3180 0.0047 15 1.6 4980 0.0089 44 3980 0.0076 30 3980 0.0062 25 2990 0.0054 16 HF VH/UP Ø RUN OUT 1.7 4680 0.0100 47 3750 0.0085 32 3750 0.0070 26 2810 0.0060 17 <0.02mm 1.8 4420 0.0110 49 3540 0.0094 33 3540 0.0077 27 2650 0.0066 18 1.9 4190 0.0121 51 3350 0.0103 34 3350 0.0085 28 2510 0.0072 18 MEF 2.0 3980 0.0131 52 3180 0.0112 35 3180 0.0092 29 2390 0.0079 19 2.1 3790 0.0142 54 3030 0.0120 37 3030 0.0099 30 2270 0.0085 19 2.2 3620 0.0152 55 2900 0.0129 38 2900 0.0107 31 2170 0.0091 20 ALU 2.3 3460 0.0163 56 2770 0.0138 38 2770 0.0114 32 2080 0.0098 20 2.4 3320 0.0173 58 2650 0.0147 39 2650 0.0121 32 1990 0.0104 21 2.5 3180 0.0184 58 2550 0.0156 40 2550 0.0129 33 1910 0.0110 21 2.6 3060 0.0194 59 2450 0.0165 40 2450 0.0136 33 1840 0.0117 21 MEX 2.7 2950 0.0205 60 2360 0.0174 41 2360 0.0143 34 1770 0.0123 22 2.8 2840 0.0215 60 2270 0.0183 42 2270 0.0151 34 1710 0.0129 22 2.9 2750 0.0226 60 2200 0.0192 42 2200 0.0158 35 1650 0.0135 22 UH 3.0 2650 0.0236 60 2120 0.0201 43 2120 0.0165 35 1590 0.0142 23 *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 153

Общий каталог Osawa 2021

Общий каталог Osawa 2021