Общий каталог Osawa 2018 - страница 151

Навигация

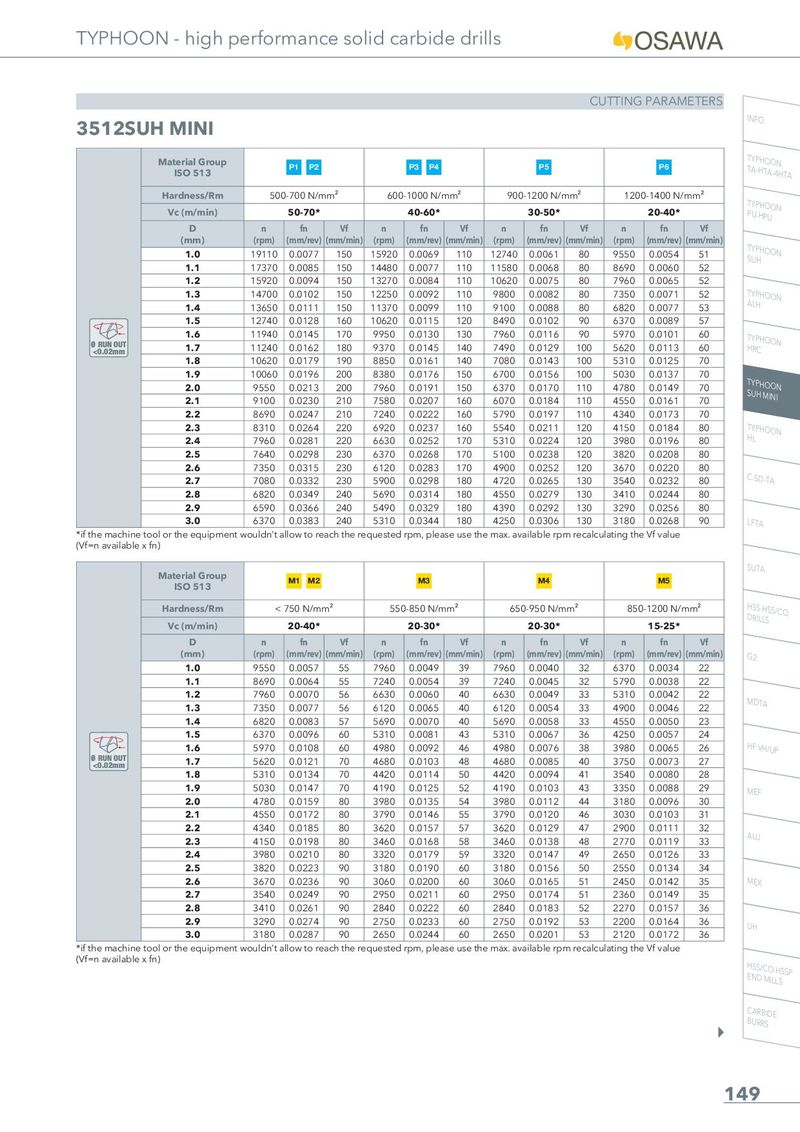

TYPHOON - high performance solid carbide drills CUTTING PARAMETERS 3512SUH MINI INFO Material Group P1 P2 P3 P4 P5 P6 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm 500-700 N/mm² 600-1000 N/mm² 900-1200 N/mm² 1200-1400 N/mm² TPYUP-HHPOUON Vc (m/min) 50-70* 40-60* 30-50* 20-40* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) TSUYPHHOON 1.0 19110 0.0077 150 15920 0.0069 110 12740 0.0061 80 9550 0.0054 51 1.1 17370 0.0085 150 14480 0.0077 110 11580 0.0068 80 8690 0.0060 52 1.2 15920 0.0094 150 13270 0.0084 110 10620 0.0075 80 7960 0.0065 52 1.3 14700 0.0102 150 12250 0.0092 110 9800 0.0082 80 7350 0.0071 52 TAYLPHHOON 1.4 13650 0.0111 150 11370 0.0099 110 9100 0.0088 80 6820 0.0077 53 1.5 12740 0.0128 160 10620 0.0115 120 8490 0.0102 90 6370 0.0089 57 1.6 11940 0.0145 170 9950 0.0130 130 7960 0.0116 90 5970 0.0101 60 THYRPCHOON Ø RUN OUT 1.7 11240 0.0162 180 9370 0.0145 140 7490 0.0129 100 5620 0.0113 60 <0.02mm 1.8 10620 0.0179 190 8850 0.0161 140 7080 0.0143 100 5310 0.0125 70 1.9 10060 0.0196 200 8380 0.0176 150 6700 0.0156 100 5030 0.0137 70 TSUYPHHMOIONIN 2.0 9550 0.0213 200 7960 0.0191 150 6370 0.0170 110 4780 0.0149 70 2.1 9100 0.0230 210 7580 0.0207 160 6070 0.0184 110 4550 0.0161 70 2.2 8690 0.0247 210 7240 0.0222 160 5790 0.0197 110 4340 0.0173 70 2.3 8310 0.0264 220 6920 0.0237 160 5540 0.0211 120 4150 0.0184 80 THYLPHOON 2.4 7960 0.0281 220 6630 0.0252 170 5310 0.0224 120 3980 0.0196 80 2.5 7640 0.0298 230 6370 0.0268 170 5100 0.0238 120 3820 0.0208 80 2.6 7350 0.0315 230 6120 0.0283 170 4900 0.0252 120 3670 0.0220 80 2.7 7080 0.0332 230 5900 0.0298 180 4720 0.0265 130 3540 0.0232 80 C-SD-TA 2.8 6820 0.0349 240 5690 0.0314 180 4550 0.0279 130 3410 0.0244 80 2.9 6590 0.0366 240 5490 0.0329 180 4390 0.0292 130 3290 0.0256 80 3.0 6370 0.0383 240 5310 0.0344 180 4250 0.0306 130 3180 0.0268 90 LFTA *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) Material Group SUTA ISO 513 M1 M2 M3 M4 M5 Hardness/Rm < 750 N/mm² 550-850 N/mm² 650-950 N/mm² 850-1200 N/mm² HDSRSIL-LHSSS/CO Vc (m/min) 20-40* 20-30* 20-30* 15-25* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) G2 1.0 9550 0.0057 55 7960 0.0049 39 7960 0.0040 32 6370 0.0034 22 1.1 8690 0.0064 55 7240 0.0054 39 7240 0.0045 32 5790 0.0038 22 1.2 7960 0.0070 56 6630 0.0060 40 6630 0.0049 33 5310 0.0042 22 MDTA 1.3 7350 0.0077 56 6120 0.0065 40 6120 0.0054 33 4900 0.0046 22 1.4 6820 0.0083 57 5690 0.0070 40 5690 0.0058 33 4550 0.0050 23 1.5 6370 0.0096 60 5310 0.0081 43 5310 0.0067 36 4250 0.0057 24 1.6 5970 0.0108 60 4980 0.0092 46 4980 0.0076 38 3980 0.0065 26 HF VH/UP Ø RUN OUT 1.7 5620 0.0121 70 4680 0.0103 48 4680 0.0085 40 3750 0.0073 27 <0.02mm 1.8 5310 0.0134 70 4420 0.0114 50 4420 0.0094 41 3540 0.0080 28 1.9 5030 0.0147 70 4190 0.0125 52 4190 0.0103 43 3350 0.0088 29 MEF 2.0 4780 0.0159 80 3980 0.0135 54 3980 0.0112 44 3180 0.0096 30 2.1 4550 0.0172 80 3790 0.0146 55 3790 0.0120 46 3030 0.0103 31 2.2 4340 0.0185 80 3620 0.0157 57 3620 0.0129 47 2900 0.0111 32 ALU 2.3 4150 0.0198 80 3460 0.0168 58 3460 0.0138 48 2770 0.0119 33 2.4 3980 0.0210 80 3320 0.0179 59 3320 0.0147 49 2650 0.0126 33 2.5 3820 0.0223 90 3180 0.0190 60 3180 0.0156 50 2550 0.0134 34 2.6 3670 0.0236 90 3060 0.0200 60 3060 0.0165 51 2450 0.0142 35 MEX 2.7 3540 0.0249 90 2950 0.0211 60 2950 0.0174 51 2360 0.0149 35 2.8 3410 0.0261 90 2840 0.0222 60 2840 0.0183 52 2270 0.0157 36 2.9 3290 0.0274 90 2750 0.0233 60 2750 0.0192 53 2200 0.0164 36 UH 3.0 3180 0.0287 90 2650 0.0244 60 2650 0.0201 53 2120 0.0172 36 *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 149

Общий каталог Osawa 2021

Общий каталог Osawa 2021