Общий каталог Lamina Technologies 2019 - 2020 - страница 174

Навигация

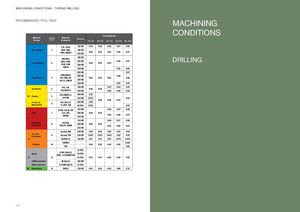

MACHINING CONDITIONS - THREAD MILLING USER GUIDE RECOMMENDED TOOL FEED MACHINING Feed (mm/tooth) CONDITIONS MaterialGroup LaminaGr. N° MaterialExamples Hardness 1.5 - 3.0 3.0 - 5.0 5.0 - 7.0 7.0 - 9.0 9.0 - 11.0 C35, Ck45, 125 HB 0.03 0.04 0.06 0.07 0.09 Non Alloyed 1 1020, 1045, 190 HB 1060, 28Mn6 0.02 0.03 0.05 0.06 0.07250 HB 42CrMo4, 180 HBLow AlloyedP2St50, Ck60,4140, 4340,230 HB 0.06 0.070.020.030.05280 HBDRILLING 100Cr6 350 HB 0.05 0.05 220 HB 0.07 X40CrMoV5, 280 HB 0.06 High Alloyed 3 H13, M42, D3, 0.02 0.03 0.05 0.06 S6-5-2, 12Ni19 320 HB 350 HB 0.05 0.05 Austenitic 4 304, 316,X5CrNi18-9180 HB 0.03 0.04 0.050.020.02240 HB0.020.060.04 M Duplex 5 X2CrNiN23-4, 290 HB 0.02S31500310 HB0.015 0.04 0.02 0.02 0.03 Ferritic &Martensitic 6 410, X6Cr17, 200 HB 0.0217-4PH, 43042 HRc0.015 0.03 GG20, GG40, EN- 150 HB 0.06 0.07 0.08 Grey 7 GJL-250, 200 HB 0.02 0.03 N030B 250 HB 0.05 0.06 0.07 K 150 HB 0.06 0.07 0.08 Malleable& Nodular 8 GGG40,GGG70, 50005200 HB 0.02 0.03 0.05 0.06 0.07 250 HB Incoloy 800 240 HB 0.02 0.02 0.02 0.03 0.04 Fe, Ni &Co based 9 Inconel 700 250 HB 0.015 0.015 0.015 0.02 0.02 S Stellite 21 350 HB 0.01 0.01 0.01 0.015 0.015 TiAl6V4 - 0.025 Ti based 10 0.02 0.02 0.02 0.02 T40 - 0.02 45 HRc Steel X100 CrMo13,440C, G-X260NiCr4250 HRc H 11 55 HRc 0.01 0.01 0.02 0.02 0.02 Chilled Cast Iron Ni-Hard 2 400 HB White Cast Iron G-X300CrMo15 55 HRc NF Aluminium 12 AlSi12 130 HB 0.03 0.03 0.04 0.08 0.12 344 345

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018