Общий каталог Lamina Technologies 2019 - 2020 - страница 167

Навигация

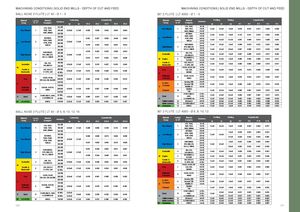

MACHINING CONDITIONS | SOLID END MILLS - DEPTH OF CUT AND FEED MACHINING CONDITIONS | SOLID END MILLS - DEPTH OF CUT AND FEED BALL NOSE 2 FLUTE | LT 40 - Ø 1 - 5 90° 2 FLUTE | LT 4000 - Ø 1 - 5 MaterialGroup LaminaGr. N° MaterialExamples* ContouringHardnessapae fz [mm/tooth]Ø1.0Ø2.0Ø3.0Ø4.0Ø5.0 MaterialGroup Lamina MaterialGr. N°ExamplesHardness Profilingapae Slottingap Ø1 fz [mm/tooth]Ø2Ø3Ø4 Ø5 C35, Ck45, 125 HB C35, Ck45, 125 HBNon Alloyed11020, 1045,190 HB1.5xØ0.5xØ1.0xØ0.0100.012 0.017 0.024 0.030 Non-Alloyed 1 1020, 1045, 190 HB 0.25xØ 0.7xØ 0.028 0.036 0.052 0.064 0.084 1060, 28Mn6 250 HB 1060, 28Mn6 250 HB42CrMo4,180 HB 0.021 0.027 0.039 0.048 0.063Low Alloyed2PSt50, Ck60,4140, 4340,230 HB0.25xØ0.7xØ280 HB100Cr6350 HB0.0180.0230.0330.0410.054220 HBX40CrMoV5,280 HB0.0180.0230.0330.0400.053High Alloyed3H13, M42, D3,0.25xØ0.7xØS6-5-2, 12Ni19320 HB0.0130.0170.0250.0310.040350 HBPLow Alloyed242CrMo4,St50, Ck60,4140, 4340,100Cr6180 HB230 HB1.5xØ0.5xØ1.0xØ0.1100.0110.0160.0250.030280 HB350 HB1.5xØ0.5xØ0.7xØ0.0070.0090.0140.0200.024High Alloyed3X40CrMoV5,H13, M42, D3,S6-5-2, 12Ni19220 HB280 HB320 HB350 HB1.5xØ0.5xØ1.0xØ0.0090.0100.0150.0210.0261.5xØ0.5xØ0.6xØ0.0070.0080.0110.0160.020Austenitic4304, 316,X5CrNi18-9180 HB240 HB1.5xØ0.5xØ1.0xØ0.0070.0080.0120.0170.022MDuplex5X2CrNiN23-4,S31500290 HB310 HB1.5xØ0.5xØ1.0xØ0.0060.0060.0090.0130.017 Austenitic 4 304, 316,X5CrNi18-9180 HB 0.25xØ 0.7xØ 0.015240 HB0.019 0.027 0.033 0.044M Ferritic &Martensitic6 410, X6Cr17,17-4PH, 430 200 HB42 HRc1.5xØ 0.5xØ 1.0xØ 0.006 0.006 0.009 0.013 0.017GG20, GG40, EN-150 HB Ferritic &Martensitic6 410, X6Cr17,17-4 PH, 430200 HB0.25xØ42 HRc0.7xØ 0.015 0.020 0.028 0.035 0.046150 HBGrey7GG20, GG40,EN-GJL-250, No30B200 HB0.25xØ0.7xØ0.0250.0320.0460.0560.074Grey7GJL-250, 200 HB 1.5xØ 0.5xØ 1.0xØ 0.012 0.014 0.020 0.029 0.036KMalleable& NodularN030B250 HB8GG20, GG70,50005150 HB200 HB250 HB1.5xØ0.5xØ1.0xØ0.0100.0120.0170.0250.031 250 HBK150 HBMalleable& Nodular8GGG40, GGG70,50005200 HB0.25xØ0.7xØ0.0210.0270.0400.0490.064250 HB Fe, Ni &SCo based Incoloy 800 240 HB9Inconel 700250 HB1.5xØ0.3xØ1.0xØ 0.006 0.007 0.010 0.014 0.018Stellite 21350 HBTi based10TiAl6V4T40--1.5xØ0.5xØ1.0xØ0.0060.0070.0100.0150.018 H Steel 11 X100CrMo13, 440C, 45 HRcG-X260NiCr4250 HRc0.25xØ0.6xØ0.009 0.012 0.017 0.020 0.027 Steel X100 CrMo13,11440C, 45 HRc50 HRc1.5xØ 0.3xØ 0.2xØ 0.004 0.007 0.007 0.011 0.013HG-X260NiCr4255 HRc1.5xØ0.2xØ0.1xØ0.0030.0050.0050.0080.010 NF Al (>8%Si) 12 AlSi12 130 HB 0.25xØ 0.7xØ 0.022 0.029 0.042 0.051 0.067 Chilled Cast Iron 12 Ni-Hard 2 400 HB 1.5xØ 0.2xØ 0.1xØ 0.003 0.005 0.005 0.008 0.010 White Cast Iron 13 G-X300CrMo15 55 HRc 1.5xØ 0.2xØ 0.1xØ 0.003 0.005 0.005 0.008 0.010 NF Aluminium 14 AlSi12 130 HB 1.5xØ 0.5xØ 1.0xØ 0.011 0.018 0.018 0.027 0.033 BALL NOSE 2 FLUTE | LT 40 - Ø 6, 8, 10, 12, 16 90° 2 FLUTE | LT 4000 - Ø 6, 8, 10, 12 MaterialGroup LaminaGr. N° MaterialExamples* ContouringHardnessapae fz [mm/tooth]Ø6.0Ø8.0Ø10.0Ø12.0Ø16.0 MaterialGroup Lamina MaterialGr. N°ExamplesHardness Profilingapae Slottingap Ø6 fz [mm/tooth]Ø8Ø 10 Ø 12 C35, Ck45, 125 HB C35, Ck45, 125 HBNon Alloyed11020, 1045,190 HB1.5xØ0.5xØ1.0xØ0.0400.055 0.065 0.077 Non-Alloyed 1 1020, 1045, 190 HB 0.25xØ 0.7xØ 0.080 0.092 0.100 0.112 0.106 1060, 28Mn6 250 HB 1060, 28Mn6 250 HB42CrMo4,180 HB 0.060 0.069 0.075 0.084 0.080Low Alloyed2PSt50, Ck60,4140, 4340,230 HB0.25xØ0.7xØ280 HB100Cr6350 HB0.0510.0590.0640.0720.068220 HBX40CrMoV5,280 HB0.0510.0580.0630.0710.067High Alloyed3H13, M42, D3,0.25xØ0.7xØS6-5-2, 12Ni19320 HB0.0380.0440.0480.0540.051350 HBPLow Alloyed242CrMo4,St50, Ck60,4140, 4340,100Cr6180 HB230 HB280 HB350 HB1.0xØ0.0390.0530.0630.0741.5xØ0.5xØ0.7xØ0.0320.0430.0520.062High Alloyed3X40CrMoV5,H13, M42, D3,S6-5-2, 12Ni19220 HB280 HB320 HB350 HB1.0xØ0.0330.0460.0550.0641.5xØ0.5xØ0.6xØ0.0250.0350.0410.049Austenitic4304, 316,X5CrNi18-9180 HB240 HB1.5xØ0.5xØ1.0xØ0.0280.0380.0450.053MDuplex5X2CrNiN23-4,S31500290 HB310 HB1.5xØ0.5xØ1.0xØ0.0210.0290.0350.040 Austenitic 4 304, 316,X5CrNi18-9180 HB 0.25xØ 0.7xØ 0.042240 HB0.048 0.052 0.058 0.055M Ferritic &Martensitic6 410, X6Cr17,17-4PH, 430 200 HB42 HRc1.5xØ 0.5xØ 1.0xØ 0.021 0.029 0.035 0.040GG20, GG40, EN-150 HB Ferritic &Martensitic6 410, X6Cr17,17-4 PH, 430200 HB0.25xØ42 HRc0.7xØ 0.044 0.050 0.054 0.061 0.058150 HBGrey7GG20, GG40,EN-GJL-250, No30B200 HB0.25xØ0.7xØ0.0700.0810.0880.0990.093250 HBK150 HBMalleable& Nodular8GGG40, GGG70,50005200 HB0.25xØ0.7xØ0.0610.0700.0760.0850.081250 HBGrey7GJL-250,200 HB1.5xØ0.5xØ1.0xØ0.0470.0640.0760.089KMalleable& NodularN030B250 HB8GG20, GG70,50005150 HB200 HB250 HB1.5xØ0.5xØ1.0xØ0.0400.0550.0660.077Fe, Ni &SCo basedIncoloy 800240 HB9Inconel 700250 HB1.5xØ0.3xØ1.0xØ0.0230.0310.0370.044Stellite 21350 HBTi based10TiAl6V4T40--1.5xØ0.5xØ1.0xØ0.0230.0320.0380.045 H Steel 11 X100CrMo13, 440C, 45 HRcG-X260NiCr4250 HRc0.25xØ0.25xØ0.6xØ0.0260.029 0.032 0.036 0.034 Steel X100 CrMo13,11440C, 45 HRc50 HRc1.5xØ 0.3xØ 0.2xØ 0.017 0.023 0.028 0.032HG-X260NiCr4255 HRc0.2xØ0.1xØ0.0130.0170.0210.024 NF Al (>8%Si) 12 AlSi12 130 HB 0.25xØ 0.7xØ 0.064 0.074 0.080 0.090 0.085 Chilled Cast Iron 12 Ni-Hard 2 400 HB 1.5xØ 0.2xØ 0.1xØ 0.013 0.017 0.021 0.024 White Cast Iron 13 G-X300CrMo15 55 HRc 1.5xØ 0.2xØ 0.1xØ 0.013 0.017 0.021 0.024 NF Aluminium 14 AlSi12 130 HB 1.5xØ 0.5xØ 1.0xØ 0.042 0.058 0.069 0.081 330 331

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018