Общий каталог Lamina Technologies 2019 - 2020 - страница 159

Навигация

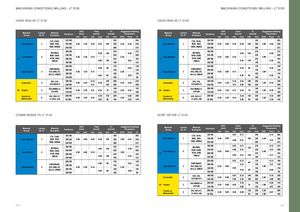

MACHINING CONDITIONS | MILLING - LT 3130 MACHINING CONDITIONS | MILLING - LT 3130 HNKX 0604-45 LT 3130 ONKX 0806-45 LT 3130 MaterialGroup LaminaGr. N° MaterialExamplesHardness DOC[mm] Feed Vc Suggested Starting[mm/z][m/min]Parameters MaterialGroup LaminaGr. N° MaterialExamplesHardness DOC[mm] Feed Vc Suggested Starting[mm/z][m/min]Parameters min max min max min max DOC Feed Vc min max min max min max DOC Feed Vc C35, Ck45, 125 HB 350 265 C35, Ck45, 125 HB 350 265 Non Alloyed 1 1020, 1045, 190 HB 0.50 3.50 0.16 0.34 190 320 2.50 0.30 240 Non Alloyed 1 1020, 1045, 190 HB 0.50 4.00 0.16 0.58 190 320 3.00 0.46 240 1060, 28Mn6 250 HB 280 215 1060, 28Mn6 250 HB 280 215 42CrMo4, 180 HB 270 2150.281500.26 42CrMo4, 180 HB 270 2150.501500.40 Low AlloyedP 2 St50, Ck60,4140, 4340,230 HB0.50 3.50 0.14280 HB 230 2002.50210165 Low AlloyedP 2 St50, Ck60,4140, 4340,230 HB0.50 4.00 0.14280 HB 230 2003.00210165 100Cr6 350 HB 0.26 130 0.24190 155 100Cr6 350 HB 0.44 130 0.36190 155 220 HB 170 140 220 HB 170 140 X40CrMoV5, 280 HB 0.28 90 0.26150 130 X40CrMoV5, 280 HB 0.44 90 0.36150 130 High Alloyed 3 H13, M42, D3, 0.50 3.50 0.11 2.50 High Alloyed 3 H13, M42, D3, 0.50 4.00 0.11 3.00 S6-5-2, 12Ni19 320 HB 120 1100.24600.22 S6-5-2, 12Ni19 320 HB 120 1100.36600.32 350 HB 100 90 350 HB 100 90 Austenitic 4 304, 316,X5CrNi18-9180 HB 0.14 190 260 2300.503.500.302.500.26240 HB0.11160220200Austenitic4 304, 316,X5CrNi18-9180 HB 0.14 0.44 190 260 2300.501.501.200.34240 HB0.110.40160220200 M Duplex 5 X2CrNiN23-4,S31500290 HB 0.50 3.50 0.11 0.25310 HB70 140 1102.500.22130100 M Duplex 5 X2CrNiN23-4,S31500290 HB 0.50 1.50 0.11 0.36310 HB70 140 1101.200.30130100 Ferritic &Martensitic6 410, X6Cr17,17-4PH, 430200 HB 0.30 150 220 0.26 2000.503.500.142.5042 HRc0.25901600.22140Ferritic &Martensitic6410, X6Cr17,17-4PH, 430200 HB 0.44 150 220 0.34 2000.501.500.141.2042 HRc0.40901600.30140 ODMW 060508 TN LT 3130 SCMT 09T308 LT 3130 MaterialGroup LaminaGr. N° MaterialExamplesHardness DOC[mm] Feed Vc Suggested Starting[mm/z][m/min]ParametersminmaxminmaxminmaxDOCFeedVcMaterialGroupLaminaGr. N°MaterialExamplesDOC Feed Vc Suggested StartingHardness[mm][mm/z][m/min]ParametersminmaxminmaxminmaxDOCFeedVc C35, Ck45, 125 HB 350 265 C35, Ck45, 125 HB 0.07 0.17 350 0.15 265 Non Alloyed 1 1020, 1045, 190 HB 0.50 4.00 0.22 0.58 190 320 3.00 0.41 2401060, 28Mn6250 HB280215 Non Alloyed 1 1020, 1045, 190 HB 0.50 9.00 190 320 2.40 2401060, 28Mn6250 HB0.600.150.13280215 42CrMo4, 180 HB 270 2150.451500.36Low AlloyedP2St50, Ck60,4140, 4340,230 HB0.504.000.18280 HB2302003.00210165100Cr6350 HB0.401300.3219015542CrMo4,180 HB0.070.172700.15 215150Low AlloyedP2St50, Ck60,4140, 4340,230 HB0.060.150.509.00280 HB2300.132002.40210165100Cr6350 HB0.050.131300.11190155 220 HB 170 140X40CrMoV5,280 HB0.40900.32150130High Alloyed3H13, M42, D3,0.502.900.142.30S6-5-2, 12Ni19320 HB1201100.32600.29350 HB10090220 HB0.070.151700.13 140X40CrMoV5,280 HB900.131500.11130High Alloyed3H13, M42, D3,0.509.001.80S6-5-2, 12Ni19320 HB0.051201100.10600.08350 HB10090 Austenitic 4 304, 316,X5CrNi18-9180 HB 0.07 0.12 190 260 0.10 2300.509.002.40240 HB0.050.101602200.08200 M Duplex 5 X2CrNiN23-4,S31500290 HB 0.100.509.000.05310 HB0.08701400.08 1101.801300.07100 Ferritic &Martensitic6 410, X6Cr17,17-4PH, 430200 HB 150 220 2.40 2000.509.000.050.080.0742 HRc901601.80140 314 315

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018