Общий каталог Lamina Technologies 2019 - 2020 - страница 134

Навигация

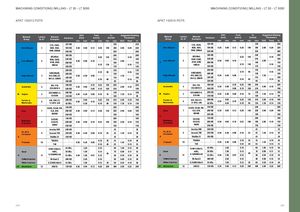

MACHINING CONDITIONS | MILLING - LT 30 - LT 3000 MACHINING CONDITIONS | MILLING - LT 30 - LT 3000 APKT 100312 PDTR APKT 100316 PDTR MaterialGroup LaminaGr. N° MaterialExamplesHardness DOC[mm] Feed Vc Suggested Starting[mm/z][m/min]ParametersminmaxminmaxminmaxDOCFeedVcMaterialGroupLaminaGr. N°MaterialExamplesHardnessDOC[mm] Feed Vc Suggested Starting[mm/z][m/min]ParametersminmaxminmaxminmaxDOCFeedVc C35, Ck45, 125 HB 330 250 C35, Ck45, 125 HB 330 250 Non Alloyed 1 1020, 1045, 190 HB 0.50 9.00 0.13 0.28 190 300 2.00 0.20 220 Non Alloyed 1 1020, 1045, 190 HB 0.50 9.00 0.13 0.28 190 300 2.00 0.20 220 1060, 28Mn6 250 HB 250 200 1060, 28Mn6 250 HB 250 200 42CrMo4, 180 HB 240 2000.221500.18Low AlloyedP2St50, Ck60,4140, 4340,230 HB0.509.000.10280 HB2101802.00190150100Cr6350 HB0.191300.1617014042CrMo4,180 HB 240 2000.221500.18Low AlloyedP2St50, Ck60,4140, 4340,230 HB0.509.000.10280 HB2101802.00190150100Cr6350 HB0.191300.16170140 220 HB 150 130X40CrMoV5,280 HB0.19900.16130120High Alloyed3H13, M42, D3,0.506.400.081.50S6-5-2, 12Ni19320 HB1101000.16600.14350 HB9080220 HB 150 130X40CrMoV5,280 HB0.19900.16130120High Alloyed3H13, M42, D3,0.506.400.081.50S6-5-2, 12Ni19320 HB1101000.16600.14350 HB9080 Austenitic 4 304, 316,X5CrNi18-9180 HB 0.10 0.22 190 250 2200.509.002.000.18240 HB0.080.19160210190Austenitic 4 304, 316,X5CrNi18-9180 HB 0.10 0.22 190 250 2200.509.002.000.18240 HB0.080.19160210190 M Duplex 5 X2CrNiN23-4,S31500290 HB 0.50 6.40 0.08 0.16310 HB70 130 1001.500.1412090 M Duplex 5 X2CrNiN23-4,S31500290 HB 0.50 6.40 0.08 0.16310 HB70 130 1001.500.1412090 Ferritic &Martensitic 6 410, X6Cr17,17-4PH, 430200 HB 9.00 0.22 150 210 2.00 0.18 1900.500.1042 HRc6.400.18901501.500.14130Ferritic &Martensitic6 410, X6Cr17,17-4PH, 430200 HB 9.00 0.22 150 210 2.00 0.18 1900.500.1042 HRc6.400.18901501.500.14130 GG20, GG40, EN- 150 HB 240 200 GG20, GG40, EN- 150 HB 240 200 Grey 7 GJL-250, 200 HB 0.50 9.00 0.13 0.28 150 220 2.00 0.20 180 Grey 7 GJL-250, 200 HB 0.50 9.00 0.13 0.28 150 220 2.00 0.20 180 N030B 250 HB 190 160 N030B 250 HB 190 160 K GGG40, 150 HB 200 180Malleable& Nodular8GGG70,200 HB0.509.000.100.251001802.000.1815050005250 HB150130KGGG40,150 HB 200 180Malleable& Nodular8GGG70,200 HB0.509.000.100.251001802.000.1815050005250 HB150130 Incoloy 800 240 HB 45 32 Incoloy 800 240 HB 45 32 Fe, Ni &Co based 9 Inconel 700 250 HB 0.50 6.40 0.08 0.16 25 45 1.50 0.14 30 Fe, Ni &Co based 9 Inconel 700 250 HB 0.50 6.40 0.08 0.16 25 45 1.50 0.14 30 S Stellite 21 350 HB 45 30 S Stellite 21 350 HB 45 30 TiAl6V4 - 0.18 30 55 0.16 40Ti based100.506.400.081.50T40-0.1640650.1455 TiAl6V4 - 0.18 30 55 0.16 40Ti based100.506.400.081.50T40-0.1640650.1455 X100 CrMo13, 45 HRc 3.20 0.16 80 1.00 0.12 60 X100 CrMo13, 45 HRc 3.20 0.16 80 1.00 0.12 60 Steel 440C, 50 HRc 1.90 0.14 70 0.80 0.11 55H11G-X260NiCr4255 HRc0.501.000.070.1240600.500.1050Steel 440C, 50 HRc 1.90 0.14 70 0.80 0.11 55H11G-X260NiCr4255 HRc0.501.000.070.1240600.500.1050 Chilled Cast Iron Ni-Hard 2 400 HB 2.60 0.16 80 0.80 0.12 50 Chilled Cast Iron Ni-Hard 2 400 HB 2.60 0.16 80 0.80 0.12 50 White Cast Iron G-X300CrMo15 55 HRc 1.00 0.12 30 60 0.50 0.10 40 White Cast Iron G-X300CrMo15 55 HRc 1.00 0.12 30 60 0.50 0.10 40 NF Aluminium 12 AlSi12 130 HB 0.50 9.00 0.13 0.28 200 400 2.00 0.22 280 NF Aluminium 12 AlSi12 130 HB 0.50 9.00 0.13 0.28 200 400 2.00 0.22 280 264 265

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018