Основной каталог Kyocera 2016-2017 - страница 884

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

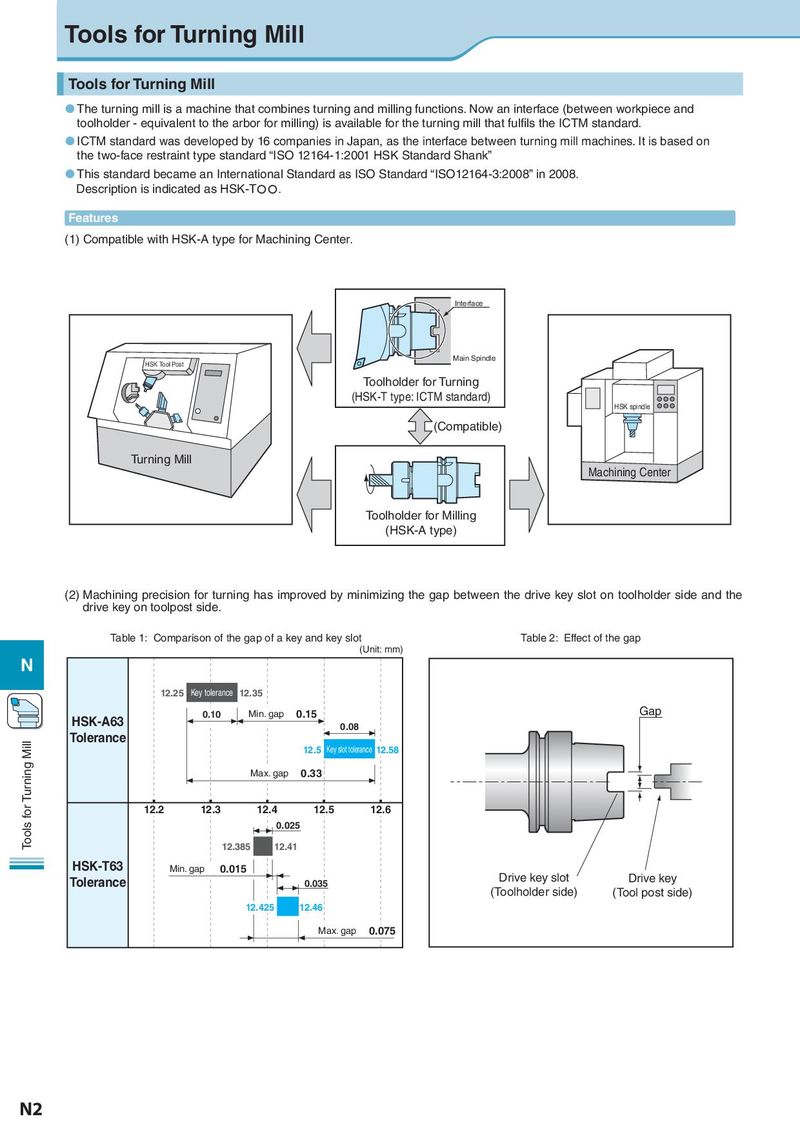

Tools for Turning Mill Tools for Turning Mill The turning mill is a machine that combines turning and milling functions. Now an interface (between workpiece and toolholder - equivalent to the arbor for milling) is available for the turning mill that fulfils the ICTM standard. ICTM standard was developed by 16 companies in Japan, as the interface between turning mill machines. It is based on the two-face restraint type standard “ISO 12164-1:2001 HSK Standard Shank” This standard became an International Standard as ISO Standard “ISO12164-3:2008” in 2008. Description is indicated as HSK-T¡¡. Features (1) Compatible with HSK-A type for Machining Center. Interface HSK Tool Post Main Spindle Toolholder for Turning (HSK-T type: ICTM standard) HSK spindle (Compatible) Turning Mill Machining Center Toolholder for Milling (HSK-A type) (2) Machining precision for turning has improved by minimizing the gap between the drive key slot on toolholder side and the drive key on toolpost side. Table 1: Comparison of the gap of a key and key slot Table 2: Effect of the gap (Unit: mm) N 12.25 Key tolerance 12.35 HSK-A63 0.10 Min. gap 0.15 Gap 0.08 Tools for Turning Mill Tolerance 12.5 Key slot tolerance 12.58 Max. gap 0.33 12.2 12.3 12.4 12.5 12.6 0.025 12.385 12.41 HSK-T63 Min. gap 0.015 Tolerance 0.035 Drive key slot Drive key (Toolholder side) (Tool post side) 12.425 12.46 Max. gap 0.075 N2