Основной каталог Kyocera 2016-2017 - страница 861

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

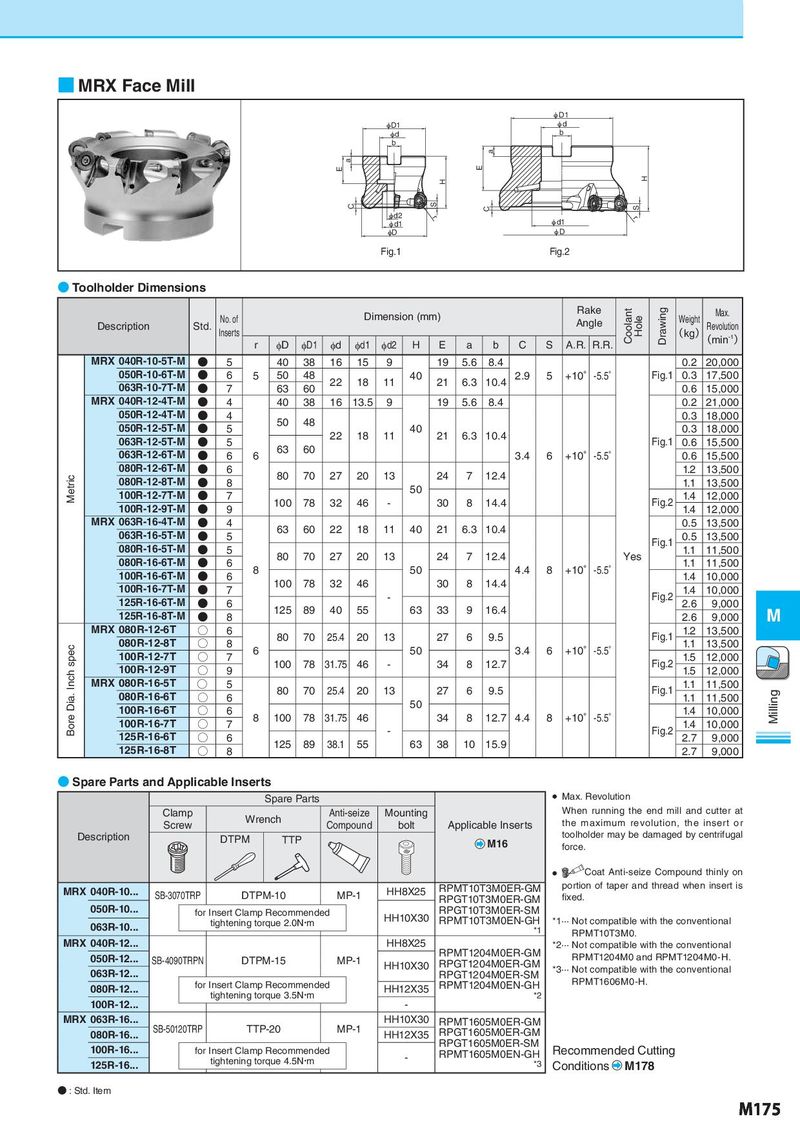

■ MRX Face Mill φ D1 φ D1 φd φd b b a a E E H H C S C S φd2 r r φ d1 φ d1 φD φD Fig.1 Fig.2 ● Toolholder Dimensions Dimension (mm) Rake Coolant Drawing (Wkeiggh)t (RemvMoialnuxt.-i1o)n Description Std. No. of Angle Hole Inserts r φD φD1 φd φd1 φd2 H E a b C S A.R. R.R. MRX 040R-10-5T-M ● 5 40 38 16 15 9 19 5.6 8.4 0.2 20,000 050R-10-6T-M ● 6 5 50 48 22 18 11 40 21 6.3 10.4 2.9 5 +10°-5.5° Fig.1 0.3 17,500 063R-10-7T-M ● 7 63 60 0.6 15,000 MRX 040R-12-4T-M ● 4 40 38 16 13.5 9 19 5.6 8.4 0.2 21,000 050R-12-4T-M ● 4 50 48 0.3 18,000 050R-12-5T-M ● 5 22 18 11 40 21 6.3 10.4 0.3 18,000 063R-12-5T-M ● 5 63 60 Fig.1 0.6 15,500 063R-12-6T-M ● 6 6 3.4 6 +10°-5.5° 0.6 15,500 080R-12-6T-M ● 6 80 70 27 20 13 24 7 12.4 1.2 13,500 Metric 080R-12-8T-M ● 8 50 1.1 13,500 100R-12-7T-M ● 7 100 78 32 46 - 30 8 14.4 Fig.2 1.4 12,000 100R-12-9T-M ● 9 1.4 12,000 MRX 063R-16-4T-M ● 4 63 60 22 18 11 40 21 6.3 10.4 0.5 13,500 063R-16-5T-M ● 5 Fig.1 0.5 13,500 080R-16-5T-M ● 5 80 70 27 20 13 24 7 12.4 Yes 1.1 11,500 080R-16-6T-M ● 6 8 50 4.4 8 +10°-5.5° 1.1 11,500 100R-16-6T-M ● 6 100 78 32 46 30 8 14.4 1.4 10,000 100R-16-7T-M ● 7 - Fig.2 1.4 10,000 125R-16-6T-M ● 6 125 89 40 55 63 33 9 16.4 2.6 9,000 125R-16-8T-M ● 8 2.6 9,000 M MRX 080R-12-6T ○ 6 80 70 25.4 20 13 27 6 9.5 Fig.1 1.2 13,500 spec 080R-12-8T ○ 8 6 50 3.4 6 +10°-5.5° 1.1 13,500 100R-12-7T ○ 7 100 78 31.75 46 - 34 8 12.7 Fig.2 1.5 12,000 Bore Dia. Inch 100R-12-9T ○ 9 1.5 12,000 MRX 080R-16-5T ○ 5 80 70 25.4 20 13 27 6 9.5 Fig.1 1.1 11,500 080R-16-6T ○ 6 50 1.1 11,500 Milling 100R-16-6T ○ 6 8 100 78 31.75 46 34 8 12.7 4.4 8 +10°-5.5° 1.4 10,000 100R-16-7T ○ 7 - Fig.2 1.4 10,000 125R-16-6T ○ 6 125 89 38.1 55 63 38 10 15.9 2.7 9,000 125R-16-8T ○ 8 2.7 9,000 ● Spare Parts and Applicable Inserts Spare Parts ● Max. Revolution Clamp Wrench Anti-seize Mounting When running the end mill and cutter at Screw Compound bolt Applicable Inserts the maximum revolution, the insert or Description DTPM TTP M16 toolholder may be damaged by centrifugal force. ● Coat Anti-seize Compound thinly on MRX 040R-10... HH8X25 RPMT10T3M0ER-GM portion of taper and thread when insert is SB-3070TRP DTPM-10 MP-1 RPGT10T3M0ER-GM fixed. 050R-10... for Insert Clamp Recommended HH10X30 RPGT10T3M0ER-SM 063R-10... tightening torque 2.0N・m RPMT10T3M0EN-GH *1··· Not compatible with the conventional *1 RPMT10T3M0. MRX 040R-12... HH8X25 *2··· Not compatible with the conventional 050R-12... SB-4090TRPN DTPM-15 MP-1 RPMT1204M0ER-GM RPMT1204M0 and RPMT1204M0-H. HH10X30 RPGT1204M0ER-GM *3··· Not compatible with the conventional 063R-12... RPGT1204M0ER-SM RPMT1606M0-H. 080R-12... for Insert Clamp Recommended HH12X35 RPMT1204M0EN-GH tightening torque 3.5N・m *2 100R-12... - MRX 063R-16... HH10X30 RPMT1605M0ER-GM 080R-16... SB-50120TRP TTP-20 MP-1 HH12X35 RPGT1605M0ER-GM 100R-16... for Insert Clamp Recommended RPGT1605M0ER-SM Recommended Cutting tightening torque 4.5N・m - RPMT1605M0EN-GH 125R-16... *3 Conditions M178 ● : Std. Item M175