Основной каталог Kyocera 2016-2017 - страница 855

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

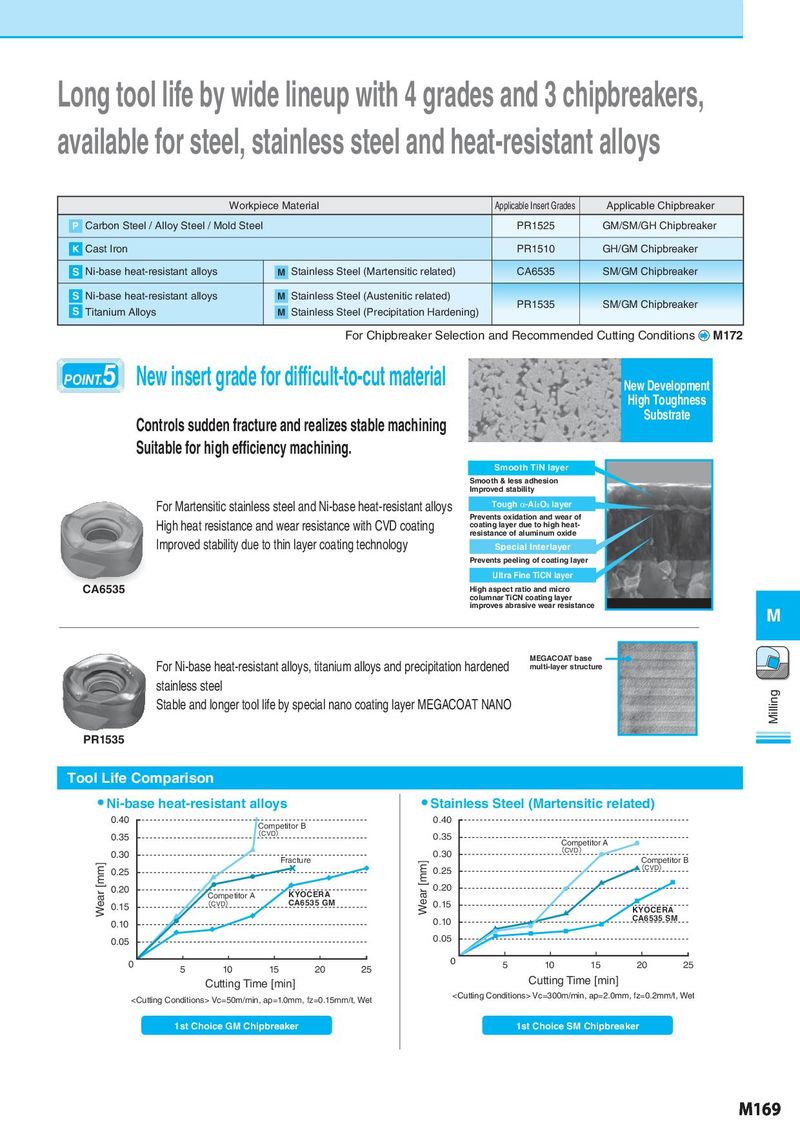

Long tool life by wide lineup with 4 grades and 3 chipbreakers,

available for steel, stainless steel and heat-resistant alloys

Workpiece Material Applicable Insert Grades Applicable Chipbreaker

P Carbon Steel / Alloy Steel / Mold Steel PR1525 GM/SM/GH Chipbreaker

K Cast Iron PR1510 GH/GM Chipbreaker

S Ni-base heat-resistant alloys M Stainless Steel (Martensitic related) CA6535 SM/GM Chipbreaker

S Ni-base heat-resistant alloys M Stainless Steel (Austenitic related) PR1535 SM/GM Chipbreaker

S Titanium Alloys M Stainless Steel (Precipitation Hardening)

For Chipbreaker Selection and Recommended Cutting Conditions M172

5 POINT. New insert grade for difficult-to-cut material New Development

High Toughness

Controls sudden fracture and realizes stable machining Substrate

Suitable for high efficiency machining.

Smooth TiN layer

Smooth & less adhesion

Improved stability

For Martensitic stainless steel and Ni-base heat-resistant alloys Tough α-Al2O3 layer

High heat resistance and wear resistance with CVD coating Prevents oxidation and wear of

coating layer due to high heat-

resistance of aluminum oxide

Improved stability due to thin layer coating technology Special Interlayer

Prevents peeling of coating layer

Ultra Fine TiCN layer

CA6535 High aspect ratio and micro

columnar TiCN coating layer

improves abrasive wear resistance M

For Ni-base heat-resistant alloys, titanium alloys and precipitation hardened MEGACOAT base

multi-layer structure

stainless steel Milling

Stable and longer tool life by special nano coating layer MEGACOAT NANO

PR1535

Tool Life Comparison

● Ni-base heat-resistant alloys ● Stainless Steel (Martensitic related)

0.40 Competitor B 0.40

0.35 (CVD) 0.35

Competitor A

0.30 0.30 (CVD)

Wear [mm] Fracture Wear [mm] Competitor B

0.25 0.25 (CVD)

0.20 KYOCERA 0.20

Competitor A CA6535 GM

0.15 (CVD) 0.15

KYOCERA

0.10 0.10 CA6535 SM

0.05 0.05

0 5 10 15 20 25 0 5 10 15 20 25

Cutting Time [min] Cutting Time [min]