Основной каталог Kyocera 2016-2017 - страница 836

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

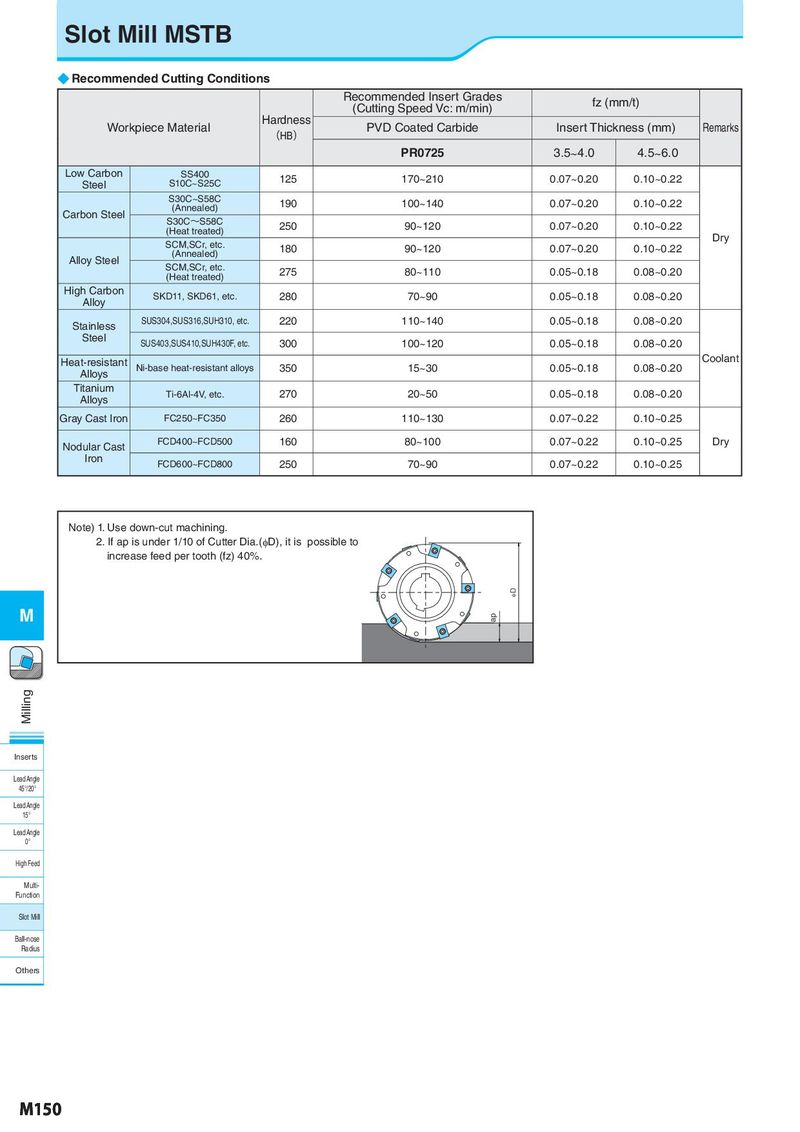

Slot Mill MSTB ◆ Recommended Cutting Conditions Recommended Insert Grades fz (mm/t) (Cutting Speed Vc: m/min) Workpiece Material Hardness PVD Coated Carbide Insert Thickness (mm) Remarks (HB) PR0725 3.5~4.0 4.5~6.0 Low Carbon SS400 125 170~210 0.07~0.20 0.10~0.22 Steel S10C~S25C S30C~S58C 190 100~140 0.07~0.20 0.10~0.22 Carbon Steel (Annealed) S30C~S58C 250 90~120 0.07~0.20 0.10~0.22 (Heat treated) Dry SCM,SCr, etc. 180 90~120 0.07~0.20 0.10~0.22 Alloy Steel (Annealed) SCM,SCr, etc. 275 80~110 0.05~0.18 0.08~0.20 (Heat treated) High Carbon SKD11, SKD61, etc. 280 70~90 0.05~0.18 0.08~0.20 Alloy Stainless SUS304,SUS316,SUH310, etc. 220 110~140 0.05~0.18 0.08~0.20 Steel SUS403,SUS410,SUH430F, etc. 300 100~120 0.05~0.18 0.08~0.20 Heat-resistant Coolant Alloys Ni-base heat-resistant alloys 350 15~30 0.05~0.18 0.08~0.20 Titanium Ti-6Al-4V, etc. 270 20~50 0.05~0.18 0.08~0.20 Alloys Gray Cast Iron FC250~FC350 260 110~130 0.07~0.22 0.10~0.25 Nodular Cast FCD400~FCD500 160 80~100 0.07~0.22 0.10~0.25 Dry Iron FCD600~FCD800 250 70~90 0.07~0.22 0.10~0.25 Note) 1. Use down-cut machining. 2. If ap is under 1/10 of Cutter Dia.(φD), it is possible to increase feed per tooth (fz) 40%. ID M ap Milling Inserts Lead Angle 45°/20° Lead Angle 15° Lead Angle 0° High Feed Multi- Function Slot Mill Ball-nose Radius Others M150