Основной каталог Kyocera 2016-2017 - страница 834

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

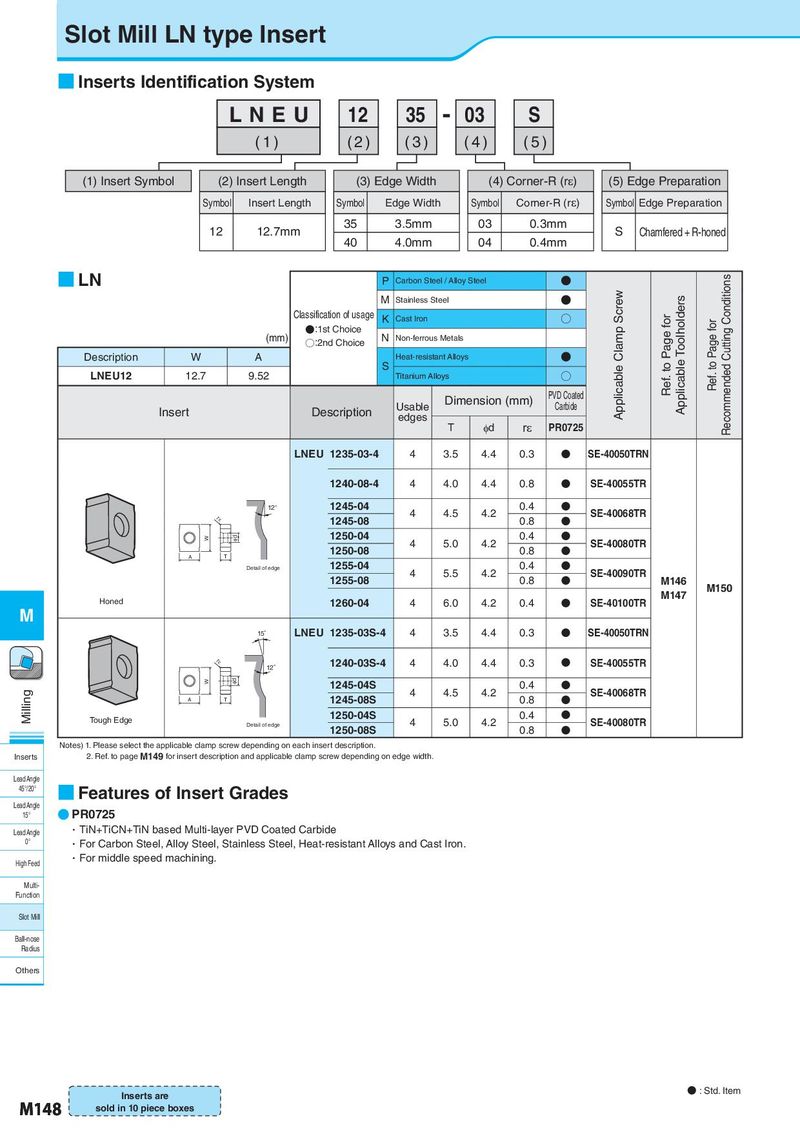

Slot Mill LN type Insert ■ Inserts Identification System LNEU 12 35 - 03 S (1) (2) (3) (4) (5) (1) Insert Symbol (2) Insert Length (3) Edge Width (4) Corner-R (rH) (5) Edge Preparation Symbol Insert Length Symbol Edge Width Symbol Corner-R (rH) Symbol Edge Preparation 12 12.7mm 35 3.5mm 03 0.3mm S Chamfered + R-honed 40 4.0mm 04 0.4mm ■ LN P Carbon Steel / Alloy Steel ● Recommended Cutting Conditions M Stainless Steel ● Applicable Clamp Screw Applicable Toolholders Classification of usage K Cast Iron ○ Ref. to Page for Ref. to Page for (mm) ●:1st Choice N ○:2nd Choice Non-ferrous Metals Description W A Heat-resistant Alloys ● LNEU12 12.7 9.52 S ○ Titanium Alloys Dimension (mm) PVD Coated Insert Description Usable Carbide edges rε T φd PR0725 LNEU 1235-03-4 4 3.5 4.4 0.3 N SE-40050TRN 1240-08-4 4 4.0 4.4 0.8 N SE-40055TR 12° 1245-04 4 4.5 4.2 0.4 N SE-40068TR rH 1245-08 0.8 N W Id 1250-04 4 5.0 4.2 0.4 N SE-40080TR A T 1250-08 0.8 N Detail of edge 1255-04 4 5.5 4.2 0.4 N SE-40090TR 1255-08 0.8 N M146 M150 Honed 1260-04 4 6.0 4.2 0.4 N SE-40100TR M147 M 15° LNEU 1235-03S-4 4 3.5 4.4 0.3 N SE-40050TRN rH 1240-03S-4 4 4.0 4.4 0.3 N SE-40055TR 12° W Id 1245-04S 0.4 N Milling A T 1245-08S 4 4.5 4.2 0.8 N SE-40068TR Tough Edge 1250-04S 4 5.0 4.2 0.4 N SE-40080TR Detail of edge 1250-08S 0.8 N Notes) 1. Please select the applicable clamp screw depending on each insert description. Inserts 2. Ref. to page M149 for insert description and applicable clamp screw depending on edge width. Lead Angle 45°/20° ■ Features of Insert Grades Lead Angle ● PR0725 15° Lead Angle ・TiN+TiCN+TiN based Multi-layer PVD Coated Carbide 0° ・For Carbon Steel, Alloy Steel, Stainless Steel, Heat-resistant Alloys and Cast Iron. High Feed ・For middle speed machining. Multi- Function Slot Mill Ball-nose Radius Others Inserts are ● : Std. Item M148 sold in 10 piece boxes