Основной каталог Kyocera 2016-2017 - страница 788

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

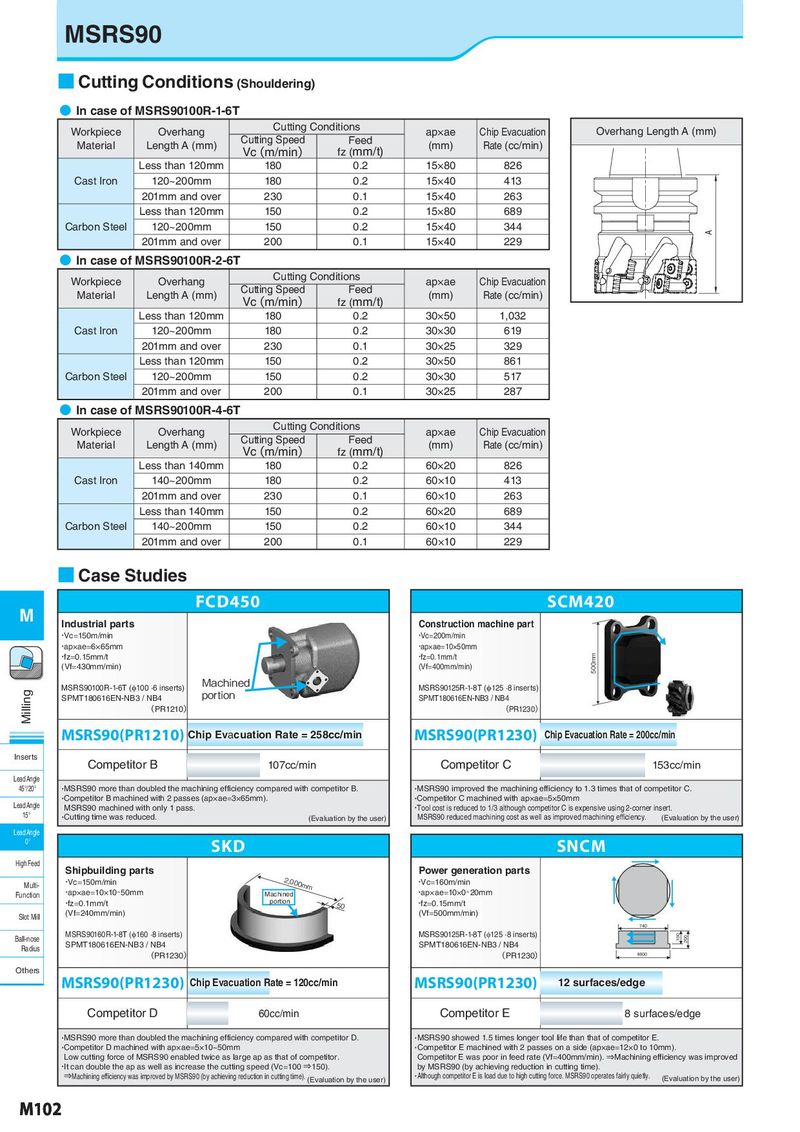

MSRS90 ■ Cutting Conditions (Shouldering) ● In case of MSRS90100R-1-6T Workpiece Overhang Cutting Conditions ap×ae Chip Evacuation Overhang Length A (mm) Material Length A (mm) Cutting Speed Feed (mm) Rate (cc/min) Vc(m/min) fz (mm/t) Less than 120mm 180 0.2 15×80 826 Cast Iron 120~200mm 180 0.2 15×40 413 201mm and over 230 0.1 15×40 263 Less than 120mm 150 0.2 15×80 689 Carbon Steel 120~200mm 150 0.2 15×40 344 A 201mm and over 200 0.1 15×40 229 ● In case of MSRS90100R-2-6T Workpiece Overhang Cutting Conditions ap×ae Chip Evacuation Material Length A (mm) Cutting Speed Feed (mm) Rate (cc/min) Vc(m/min) fz (mm/t) Less than 120mm 180 0.2 30×50 1,032 Cast Iron 120~200mm 180 0.2 30×30 619 201mm and over 230 0.1 30×25 329 Less than 120mm 150 0.2 30×50 861 Carbon Steel 120~200mm 150 0.2 30×30 517 201mm and over 200 0.1 30×25 287 ● In case of MSRS90100R-4-6T Workpiece Overhang Cutting Conditions ap×ae Chip Evacuation Material Length A (mm) Cutting Speed Feed (mm) Rate (cc/min) Vc(m/min) fz (mm/t) Less than 140mm 180 0.2 60×20 826 Cast Iron 140~200mm 180 0.2 60×10 413 201mm and over 230 0.1 60×10 263 Less than 140mm 150 0.2 60×20 689 Carbon Steel 140~200mm 150 0.2 60×10 344 201mm and over 200 0.1 60×10 229 ■ Case Studies M FCD450 SCM420 Industrial parts Construction machine part ・Vc=150m/min ・Vc=200m/min ・ap×ae=6×65mm ・ap×ae=10×50mm ・fz=0.15mm/t ・fz=0.1mm/t 500mm (Vf=430mm/min) (Vf=400mm/min) MSRS90100R-1-6T (φ100 ·6 inserts) Machined MSRS90125R-1-8T (φ125 ·8 inserts) Milling SPMT180616EN-NB3 / NB4 portion SPMT180616EN-NB3 / NB4 (PR1210) (PR1230) MSRS90(PR1210) Chip Evacuation Rate = 258cc/min MSRS90(PR1230) Chip Evacuation Rate = 200cc/min Inserts Competitor B 107cc/min Competitor C 153cc/min Lead Angle 45°/20° ・MSRS90 more than doubled the machining efficiency compared with competitor B. ・MSRS90 improved the machining efficiency to 1.3 times that of competitor C. ・Competitor B machined with 2 passes (ap×ae=3×65mm). ・Competitor C machined with ap×ae=5×50mm Lead Angle MSRS90 machined with only 1 pass. ・Tool cost is reduced to 1/3 although competitor C is expensive using 2-corner insert. 15° ・Cutting time was reduced. (Evaluation by the user) MSRS90 reduced machining cost as well as improved machining efficiency. (Evaluation by the user) Lead Angle 0° SKD SNCM High Feed Shipbuilding parts Power generation parts Multi- ・Vc=150m/min 2,000mm ・Vc=160m/min Function ・ap×ae=10×10~50mm Machined ・ap×ae=10×0~20mm ・fz=0.1mm/t portion 50 ・fz=0.15mm/t Slot Mill (Vf=240mm/min) (Vf=500mm/min) 740 Ball-nose MSRS90160R-1-8T (φ160 ·8 inserts) MSRS90125R-1-8T (φ125 ·8 inserts) 150 200 Radius SPMT180616EN-NB3 / NB4 SPMT180616EN-NB3 / NB4 (PR1230) (PR1230) φ800 Others MSRS90(PR1230) Chip Evacuation Rate = 120cc/min MSRS90(PR1230) 12 surfaces/edge Competitor D 60cc/min Competitor E 8 surfaces/edge ・MSRS90 more than doubled the machining efficiency compared with competitor D. ・MSRS90 showed 1.5 times longer tool life than that of competitor E. ・Competitor D machined with ap×ae=5×10~50mm ・Competitor E machined with 2 passes on a side (ap×ae=12×0 to 10mm). Low cutting force of MSRS90 enabled twice as large ap as that of competitor. Competitor E was poor in feed rate (Vf=400mm/min). ⇒Machining efficiency was improved ・It can double the ap as well as increase the cutting speed (Vc=100 ⇒150). by MSRS90 (by achieving reduction in cutting time). ⇒Machining efficiency was improved by MSRS90 (by achieving reduction in cutting time). (Evaluation by the user) ・Although competitor E is load due to high cutting force. MSRS90 operates fairly quietly. (Evaluation by the user) M102