Основной каталог Kyocera 2016-2017 - страница 757

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

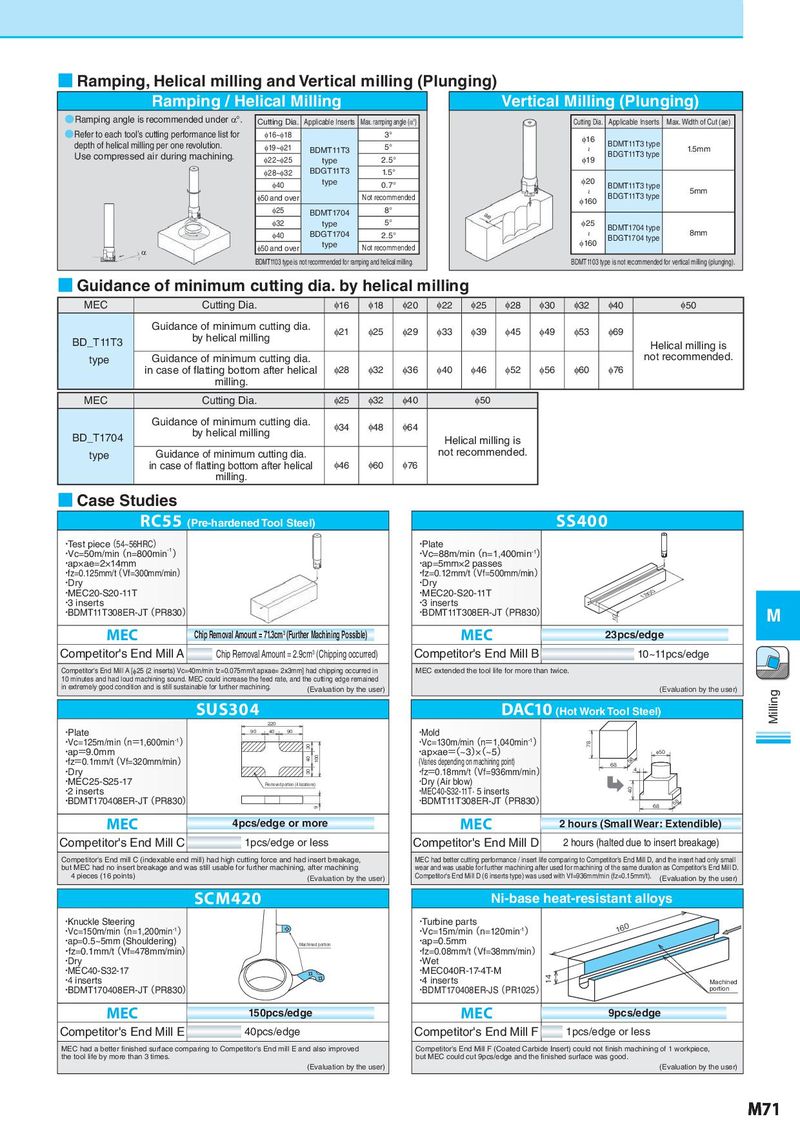

■ Ramping, Helical milling and Vertical milling (Plunging) Ramping / Helical Milling Vertical Milling (Plunging) ●Ramping angle is recommended under α°. Cutting Dia. Applicable Inserts Max. ramping angle (α°) Cutting Dia. Applicable Inserts Max. Width of Cut (ae) ●Refer to each tool’s cutting performance list for φ16~φ18 3° φ16 depth of helical milling per one revolution. φ19~φ21 BDMT11T3 5° ~ BDMT11T3 type 1.5mm Use compressed air during machining. φ22~φ25 type 2.5° φ19 BDGT11T3 type φ28~φ32 BDGT11T3 1.5° φ40 type 0.7° φ20 BDMT11T3 type ~ BDGT11T3 type 5mm φ50 and over Not recommended φ160 φ25 BDMT1704 8° φ32 type 5° φ25 BDMT1704 type φ40 BDGT1704 2.5° ~ BDGT1704 type 8mm φ50 and over type Not recommended φ160 α BDMT1103 type is not recommended for ramping and helical milling. BDMT1103 type is not recommended for vertical milling (plunging). ■ Guidance of minimum cutting dia. by helical milling MEC Cutting Dia. φ16 φ18 φ20 φ22 φ25 φ28 φ30 φ32 φ40 φ50 Guidance of minimum cutting dia. φ21 φ25 φ29 φ33 φ39 φ45 φ49 φ53 φ69 BD_T11T3 by helical milling Helical milling is type Guidance of minimum cutting dia. not recommended. in case of flatting bottom after helical φ28 φ32 φ36 φ40 φ46 φ52 φ56 φ60 φ76 milling. MEC Cutting Dia. φ25 φ32 φ40 φ50 Guidance of minimum cutting dia. φ34 φ48 φ64 BD_T1704 by helical milling Helical milling is type Guidance of minimum cutting dia. not recommended. in case of flatting bottom after helical φ46 φ60 φ76 milling. ■ Case Studies RC55 (Pre-hardened Tool Steel) SS400 ・Test piece(54~56HRC) ・Plate ・Vc=50m/min(n=800min-1) ・Vc=88m/min(n=1,400min-1) ・ap×ae=2×14mm ・ap=5mm×2 passes ・fz=0.125mm/t(Vf=300mm/min) ・fz=0.12mm/t(Vf=500mm/min) ・Dry ・Dry ・MEC20-S20-11T ・MEC20-S20-11T 1,800 ・3 inserts ・3 inserts ・BDMT11T308ER-JT(PR830) ・BDMT11T308ER-JT(PR830) 10 M MEC Chip Removal Amount = 71.3cm3 (Further Machining Possible) MEC 23pcs/edge Competitor's End Mill A Chip Removal Amount = 2.9cm3 (Chipping occurred) Competitor's End Mill B 10~11pcs/edge Competitor's End Mill A [φ25 (2 inserts) Vc=40m/min fz=0.075mm/t apxae= 2x3mm] had chipping occurred in MEC extended the tool life for more than twice. 10 minutes and had loud machining sound. MEC could increase the feed rate, and the cutting edge remained in extremely good condition and is still sustainable for further machining. (Evaluation by the user) (Evaluation by the user) Milling SUS304 DAC10 (Hot Work Tool Steel) 220 ・Plate 90 40 90 ・Mold ・Vc=125m/min(n=1,600min-1) 30 ・Vc=130m/min(n=1,040min-1) 78 ・ap=9.0mm 100 ・ap×ae=(~3)×(~5) φ50 ・fz=0.1mm/t(Vf=320mm/min) 40 (Varies depending on machining point) 58 68 ・Dry 30 ・fz=0.18mm/t(Vf=936mm/min) 4 ・MEC25-S25-17 Removed portion (4 locations) ・Dry (Air blow) ・2 inserts ・MEC40-S32-11T· 5 inserts 40 ・BDMT170408ER-JT(PR830) 9 ・BDMT11T308ER-JT(PR830) 68 58 MEC 4pcs/edge or more MEC 2 hours (Small Wear: Extendible) Competitor's End Mill C 1pcs/edge or less Competitor's End Mill D 2 hours (halted due to insert breakage) Competitor's End mill C (indexable end mill) had high cutting force and had insert breakage, MEC had better cutting performance / insert life comparing to Competitor's End Mill D, and the insert had only small but MEC had no insert breakage and was still usable for further machining, after machining wear and was usable for further machining after used for machining of the same duration as Competitor's End Mill D. 4 pieces (16 points) (Evaluation by the user) Competitor's End Mill D (6 inserts type) was used with Vf=936mm/min (fz=0.15mm/t). (Evaluation by the user) SCM420 Ni-base heat-resistant alloys ・Knuckle Steering ・Turbine parts 160 ・Vc=150m/min(n=1,200min-1) ・Vc=15m/min(n=120min-1) ・ap=0.5~5mm (Shouldering) Machined portion ・ap=0.5mm ・fz=0.1mm/t(Vf=478mm/min) ・fz=0.08mm/t(Vf=38mm/min) ・Dry ・Wet ・MEC40-S32-17 ・MEC040R-17-4T-M 14 ・4 inserts ・4 inserts Machined ・BDMT170408ER-JT(PR830) ・BDMT170408ER-JS(PR1025) portion MEC 150pcs/edge MEC 9pcs/edge Competitor's End Mill E 40pcs/edge Competitor's End Mill F 1pcs/edge or less MEC had a better finished surface comparing to Competitor's End mill E and also improved Competitor's End Mill F (Coated Carbide Insert) could not finish machining of 1 workpiece, the tool life by more than 3 times. but MEC could cut 9pcs/edge and the finished surface was good. (Evaluation by the user) (Evaluation by the user) M71