Основной каталог Kyocera 2016-2017 - страница 753

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

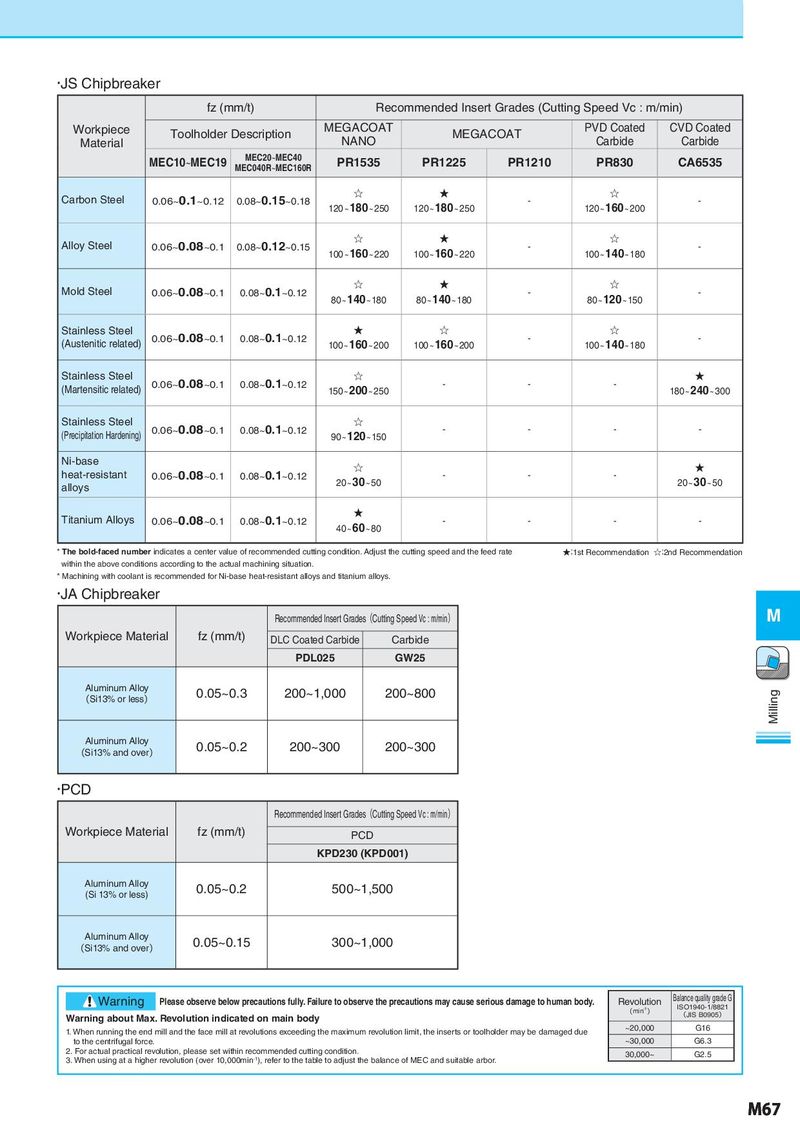

・JS Chipbreaker fz (mm/t) Recommended Insert Grades (Cutting Speed Vc : m/min) Workpiece Toolholder Description MEGACOAT MEGACOAT PVD Coated CVD Coated Material NANO Carbide Carbide MEC10~MEC19 MEC20~MEC40 PR1535 PR1225 PR1210 PR830 CA6535 MEC040R~MEC160R Carbon Steel 0.06~0.1~0.12 0.08~0.15~0.18 ☆ ★ - ☆ - 120 ~ 180 ~ 250 120 ~ 180 ~ 250 120 ~ 160 ~ 200 Alloy Steel 0.06~0.08~0.1 0.08~0.12~0.15 ☆ ★ - ☆ - 100 ~ 160 ~ 220 100 ~ 160 ~ 220 100 ~ 140 ~ 180 Mold Steel 0.06~0.08~0.1 0.08~0.1~0.12 ☆ ★ - ☆ - 80 ~ 140 ~ 180 80 ~ 140 ~ 180 80 ~ 120 ~ 150 Stainless Steel 0.06~0.08~0.1 0.08~0.1~0.12 ★ ☆ - ☆ - (Austenitic related) 100 ~ 160 ~ 200 100 ~ 160 ~ 200 100 ~ 140 ~ 180 Stainless Steel 0.06~0.08~0.1 0.08~0.1~0.12 ☆ - - - ★ (Martensitic related) 150 ~ 200 ~ 250 180 ~ 240 ~ 300 Stainless Steel 0.06~0.08~0.1 0.08~0.1~0.12 ☆ - - - - (Precipitation Hardening) 90 ~ 120 ~ 150 Ni-base ☆ ★ heat-resistant 0.06~0.08~0.1 0.08~0.1~0.12 20 ~ 30 ~ 50 - - - 20 ~ 30 ~ 50 alloys Titanium Alloys 0.06~0.08~0.1 0.08~0.1~0.12 ★ - - - - 40 ~ 60 ~ 80 * The bold-faced number indicates a center value of recommended cutting condition. Adjust the cutting speed and the feed rate ★:1st Recommendation ☆:2nd Recommendation within the above conditions according to the actual machining situation. * Machining with coolant is recommended for Ni-base heat-resistant alloys and titanium alloys. ・JA Chipbreaker Recommended Insert Grades(Cutting Speed Vc : m/min) M Workpiece Material fz (mm/t) DLC Coated Carbide Carbide PDL025 GW25 Aluminum Alloy 0.05~0.3 200~1,000 200~800 Milling (Si13% or less) Aluminum Alloy 0.05~0.2 200~300 200~300 (Si13% and over) ・PCD Recommended Insert Grades(Cutting Speed Vc : m/min) Workpiece Material fz (mm/t) PCD KPD230 (KPD001) Aluminum Alloy 0.05~0.2 500~1,500 (Si 13% or less) Aluminum Alloy 0.05~0.15 300~1,000 (Si13% and over) Warning Please observe below precautions fully. Failure to observe the precautions may cause serious damage to human body. Revolution Balance quality grade G (min-1) ISO1940-1/8821 Warning about Max. Revolution indicated on main body (JIS B0905) 1. When running the end mill and the face mill at revolutions exceeding the maximum revolution limit, the inserts or toolholder may be damaged due ~20,000 G16 to the centrifugal force. ~30,000 G6.3 2. For actual practical revolution, please set within recommended cutting condition. 30,000~ G2.5 3. When using at a higher revolution (over 10,000min-1), refer to the table to adjust the balance of MEC and suitable arbor. M67