Основной каталог Kyocera 2016-2017 - страница 733

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

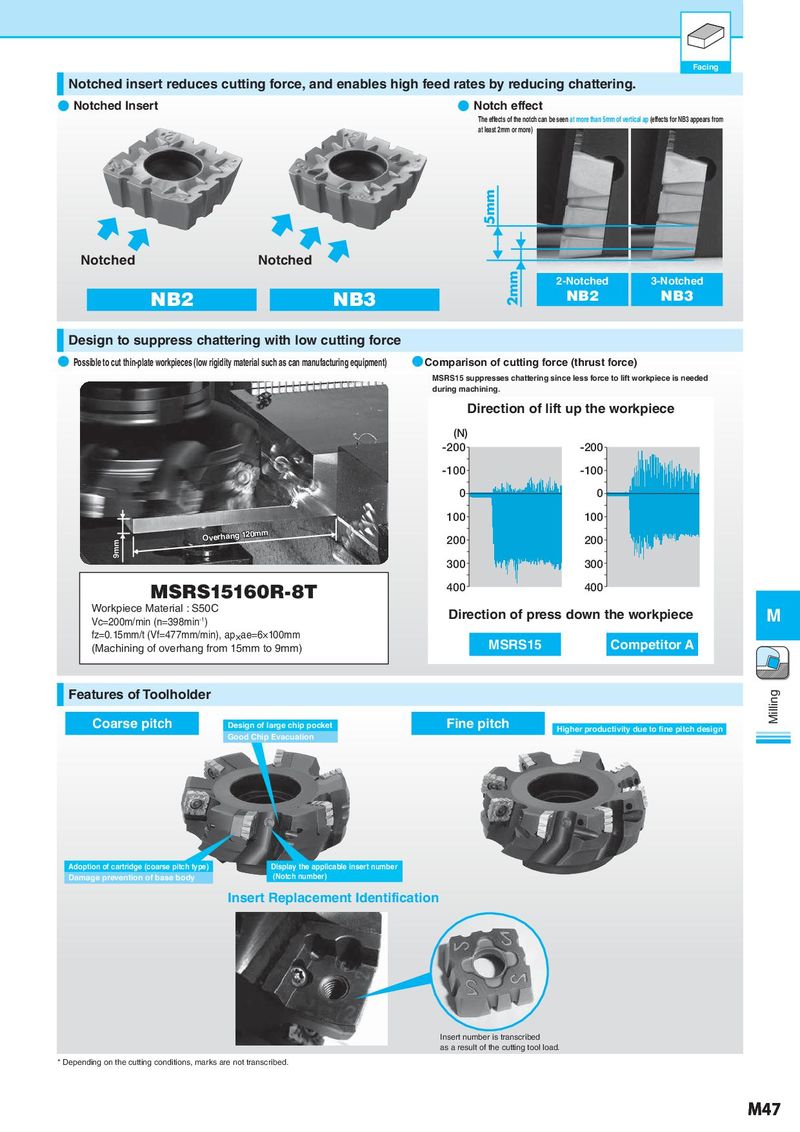

Facing Notched insert reduces cutting force, and enables high feed rates by reducing chattering. ● Notched Insert ● Notch effect The effects of the notch can be seen at more than 5mm of vertical ap (effects for NB3 appears from at least 2mm or more) 5mm Notched Notched 2mm 2-Notched 3-Notched NB2 NB3 NB2 NB3 Design to suppress chattering with low cutting force ● Possible to cut thin-plate workpieces (low rigidity material such as can manufacturing equipment) ● Comparison of cutting force (thrust force) MSRS15 suppresses chattering since less force to lift workpiece is needed during machining. Direction of lift up the workpiece (N) -200 -200 -100 -100 0 0 100 100 9mm Overhang 120mm 200 200 300 300 MSRS15160R-8T 400 400 Workpiece Material : S50C Direction of press down the workpiece M Vc=200m/min (n=398min-1) fz=0.15mm/t (Vf=477mm/min), ap×ae=6×100mm MSRS15 Competitor A (Machining of overhang from 15mm to 9mm) Features of Toolholder Milling Coarse pitch Design of large chip pocket Fine pitch Higher productivity due to fine pitch design Good Chip Evacuation Adoption of cartridge (coarse pitch type) Display the applicable insert number Damage prevention of base body (Notch number) Insert Replacement Identification Insert number is transcribed as a result of the cutting tool load. * Depending on the cutting conditions, marks are not transcribed. M47