Основной каталог Kyocera 2016-2017 - страница 719

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

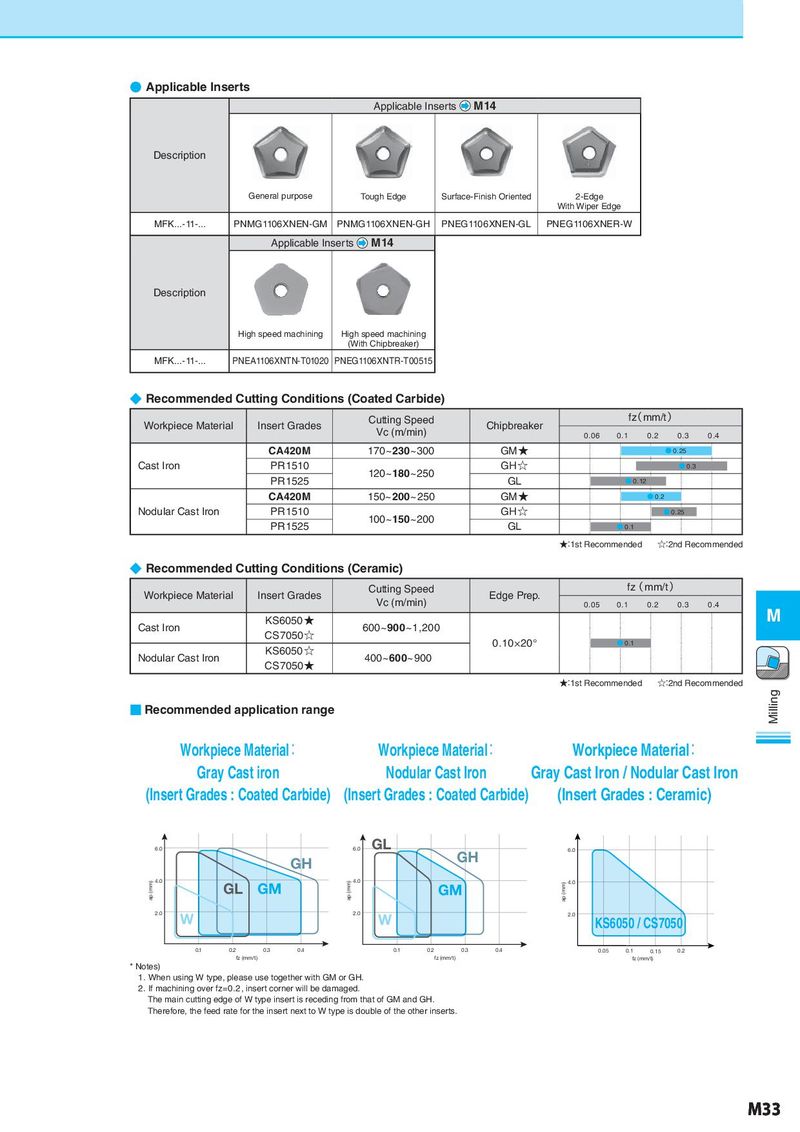

● Applicable Inserts Applicable Inserts M14 Description General purpose Tough Edge Surface-Finish Oriented 2-Edge With Wiper Edge MFK...-11-... PNMG1106XNEN-GM PNMG1106XNEN-GH PNEG1106XNEN-GL PNEG1106XNER-W Applicable Inserts M14 Description High speed machining High speed machining (With Chipbreaker) MFK...-11-... PNEA1106XNTN-T01020 PNEG1106XNTR-T00515 ◆ Recommended Cutting Conditions (Coated Carbide) Workpiece Material Insert Grades Cutting Speed Chipbreaker f(z mm/t) Vc (m/min) 0.06 0.1 0.2 0.3 0.4 CA420M 170~230~300 GM ★ ● 0.25 Cast Iron PR1510 120~180~250 GH ☆ ● 0.3 PR1525 GL ● 0.12 CA420M 150~200~250 GM ★ ● 0.2 Nodular Cast Iron PR1510 100~150~200 GH ☆ ● 0.25 PR1525 GL ● 0.1 ★:1st Recommended ☆:2nd Recommended ◆ Recommended Cutting Conditions (Ceramic) Workpiece Material Insert Grades Cutting Speed Edge Prep. fz( mm/t ) Vc (m/min) 0.05 0.1 0.2 0.3 0.4 Cast Iron KS6050 ★ 600~900~1,200 M CS 7050 ☆ 0.10×20° ● 0.1 Nodular Cast Iron KS6050 ☆ 400~600~900 CS 7050 ★ ★:1st Recommended ☆:2nd Recommended ■ Recommended application range Milling Workpiece Material: Workpiece Material: Workpiece Material: Gray Cast iron Nodular Cast Iron Gray Cast Iron / Nodular Cast Iron (Insert Grades : Coated Carbide) (Insert Grades : Coated Carbide) (Insert Grades : Ceramic) 6.0 6.0 GL 6.0 GH GH (mm) 4.0 (mm) 4.0 ap (mm) 4.0 ap GL GM ap GM 2.0 W 2.0 W 2.0 KS6050 / CS7050 0.1 0.2 0.3 0.4 0.1 0.2 0.3 0.4 0.05 0.1 0.15 0.2 fz (mm/t) fz (mm/t) fz (mm/t) * Notes) 1. When using W type, please use together with GM or GH. 2. If machining over fz=0.2, insert corner will be damaged. The main cutting edge of W type insert is receding from that of GM and GH. Therefore, the feed rate for the insert next to W type is double of the other inserts. M33