Основной каталог Kyocera 2016-2017 - страница 697

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

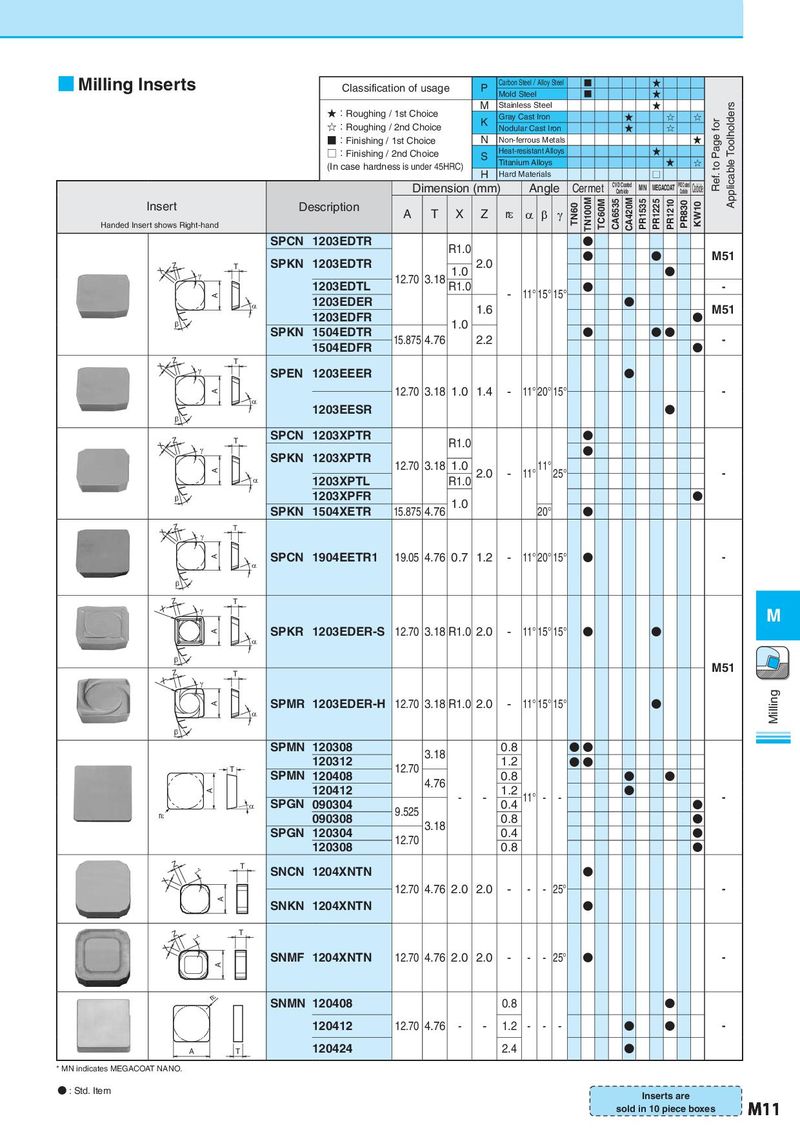

■ Milling Inserts Classification of usage P Carbon Steel / Alloy Steel ■ ★ Mold Steel ■ ★ ★:Roughing / 1st Choice M Stainless Steel ★ Applicable Toolholders K Gray Cast Iron ★ ☆ ☆ Ref. to Page for ☆:Roughing / 2nd Choice Nodular Cast Iron ★ ☆ ■:Finishing / 1st Choice N Non-ferrous Metals ★ □:Finishing / 2nd Choice S Heat-resistant Alloys ★ (In case hardness is under 45HRC) Titanium Alloys ★ ☆ H Hard Materials □ Dimension (mm) Angle Cermet CVD Coated MN MEGACOAT PVD Coated Carbide Carbide Carbide Insert Description A T X Z rε α β γ TN60 TN100M TC60M CA6535 CA420M PR1535 PR1225 PR1210 PR830 KW10 Handed Insert shows Right-hand SPCN 1203EDTR R1.0 ● SPKN 1203EDTR 2.0 ● ● M51 Z T 1.0 ● X γ 1203EDTL 12.70 3.18 R1.0 ● - A 1203EDER - 11° 15° 15° ● α 1.6 M51 β 1203EDFR 1.0 ● SPKN 1504EDTR 15.875 4.76 2.2 ● ●● - 1504EDFR ● Z T X γ SPEN 1203EEER ● A 12.70 3.18 1.0 1.4 - 11° 20° 15° - α 1203EESR ● β Z T SPCN 1203XPTR R1.0 ● X γ ● SPKN 1203XPTR 12.70 3.18 1.0 11° 11° 25° A 2.0 - - α 1203XPTL R1.0 β 1203XPFR 15.875 4.76 1.0 ● SPKN 1504XETR 20° ● Z T X γ A SPCN 1904EETR1 19.05 4.76 0.7 1.2 - 11° 20° 15° ● - α β X Z T γ M A SPKR 1203EDER-S 12.70 3.18 R1.0 2.0 - 11° 15° 15° ● ● α β M51 X Z T γ A SPMR 1203EDER-H 12.70 3.18 R1.0 2.0 - 11° 15° 15° ● Milling α β SPMN 120308 3.18 0.8 ● ● T 120312 12.70 1.2 ● ● SPMN 120408 4.76 0.8 ● ● A 120412 - - 1.2 11° - - ● SPGN 090304 0.4 ● - α 9.525 rε 090308 0.8 ● SPGN 120304 3.18 0.4 ● 120308 12.70 0.8 ● Z γ T SNCN 1204XNTN ● X 12.70 4.76 2.0 2.0 - - - 25° - A SNKN 1204XNTN ● Z γ T X A SNMF 1204XNTN 12.70 4.76 2.0 2.0 - - - 25° ● - rε SNMN 120408 0.8 ● 120412 12.70 4.76 - - 1.2 - - - ● ● - A T 120424 2.4 ● * MN indicates MEGACOAT NANO. ● : Std. Item Inserts are sold in 10 piece boxes M11