Основной каталог Kyocera 2016-2017 - страница 685

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

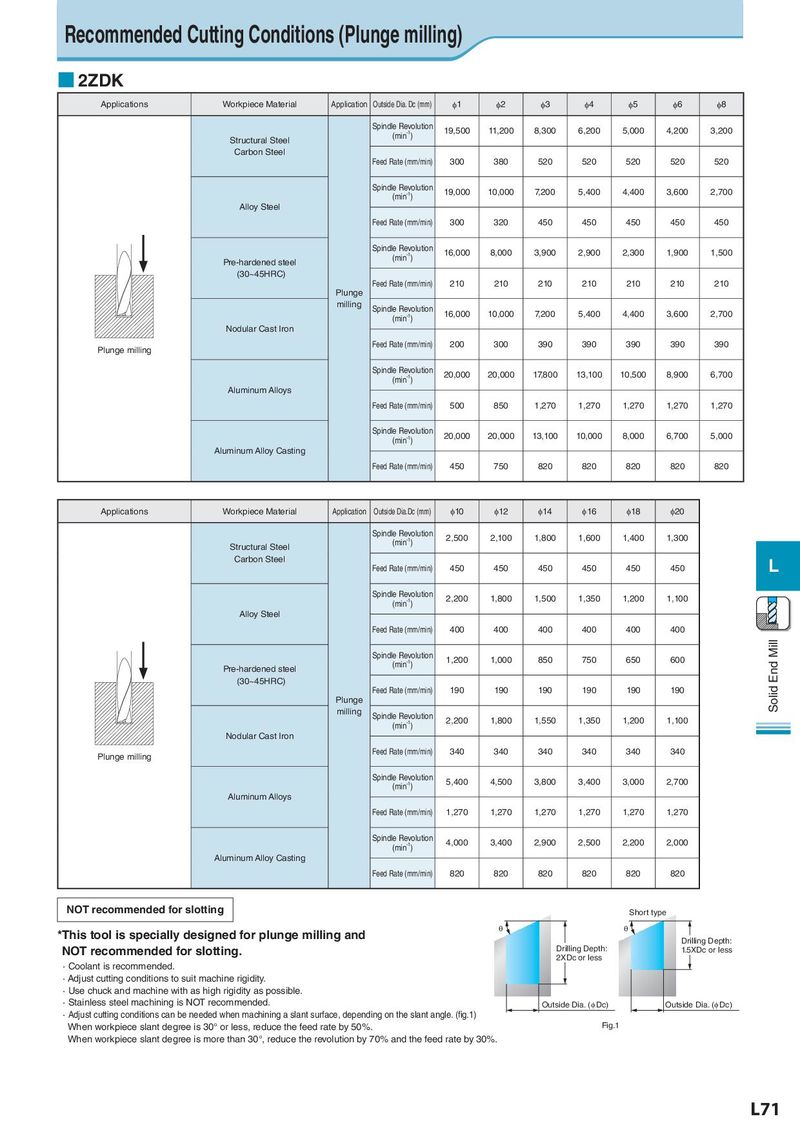

Recommended Cutting Conditions (Plunge milling) ■ 2ZDK Applications Workpiece Material Application Outside Dia. Dc (mm) φ1 φ2 φ3 φ4 φ5 φ6 φ8 Spindle Revolution 19,500 11,200 8,300 6,200 5,000 4,200 3,200 Structural Steel (min-1) Carbon Steel Feed Rate (mm/min) 300 380 520 520 520 520 520 Spindle Revolution 19,000 10,000 7,200 5,400 4,400 3,600 2,700 (min-1) Alloy Steel Feed Rate (mm/min) 300 320 450 450 450 450 450 Spindle Revolution 16,000 8,000 3,900 2,900 2,300 1,900 1,500 Pre-hardened steel (min-1) (30~45HRC) Feed Rate (mm/min) 210 210 210 210 210 210 210 Plunge milling Spindle Revolution (min-1) 16,000 10,000 7,200 5,400 4,400 3,600 2,700 Nodular Cast Iron Plunge milling Feed Rate (mm/min) 200 300 390 390 390 390 390 Spindle Revolution 20,000 20,000 17,800 13,100 10,500 8,900 6,700 (min-1) Aluminum Alloys Feed Rate (mm/min) 500 850 1,270 1,270 1,270 1,270 1,270 Spindle Revolution 20,000 20,000 13,100 10,000 8,000 6,700 5,000 (min-1) Aluminum Alloy Casting Feed Rate (mm/min) 450 750 820 820 820 820 820 Applications Workpiece Material Application Outside Dia.Dc (mm) φ10 φ12 φ14 φ16 φ18 φ20 Spindle Revolution 2,500 2,100 1,800 1,600 1,400 1,300 Structural Steel (min-1) Carbon Steel L Feed Rate (mm/min) 450 450 450 450 450 450 Spindle Revolution 2,200 1,800 1,500 1,350 1,200 1,100 (min-1) Alloy Steel Feed Rate (mm/min) 400 400 400 400 400 400 Spindle Revolution 1,200 1,000 850 750 650 600 Solid End Mill Pre-hardened steel (min-1) (30~45HRC) Feed Rate (mm/min) 190 190 190 190 190 190 Plunge milling Spindle Revolution (min-1) 2,200 1,800 1,550 1,350 1,200 1,100 Nodular Cast Iron Plunge milling Feed Rate (mm/min) 340 340 340 340 340 340 Spindle Revolution 5,400 4,500 3,800 3,400 3,000 2,700 (min-1) Aluminum Alloys Feed Rate (mm/min) 1,270 1,270 1,270 1,270 1,270 1,270 Spindle Revolution 4,000 3,400 2,900 2,500 2,200 2,000 (min-1) Aluminum Alloy Casting Feed Rate (mm/min) 820 820 820 820 820 820 NOT recommended for slotting Short type *This tool is specially designed for plunge milling and T T Drilling Depth: NOT recommended for slotting. Drilling Depth: 1.5XDc or less 2XDc or less · Coolant is recommended. · Adjust cutting conditions to suit machine rigidity. · Use chuck and machine with as high rigidity as possible. · Stainless steel machining is NOT recommended. Outside Dia. (I Dc) Outside Dia. (I Dc) · Adjust cutting conditions can be needed when machining a slant surface, depending on the slant angle. (fig.1) When workpiece slant degree is 30° or less, reduce the feed rate by 50%. Fig.1 When workpiece slant degree is more than 30°, reduce the revolution by 70% and the feed rate by 30%. L71