Основной каталог Kyocera 2016-2017 - страница 670

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

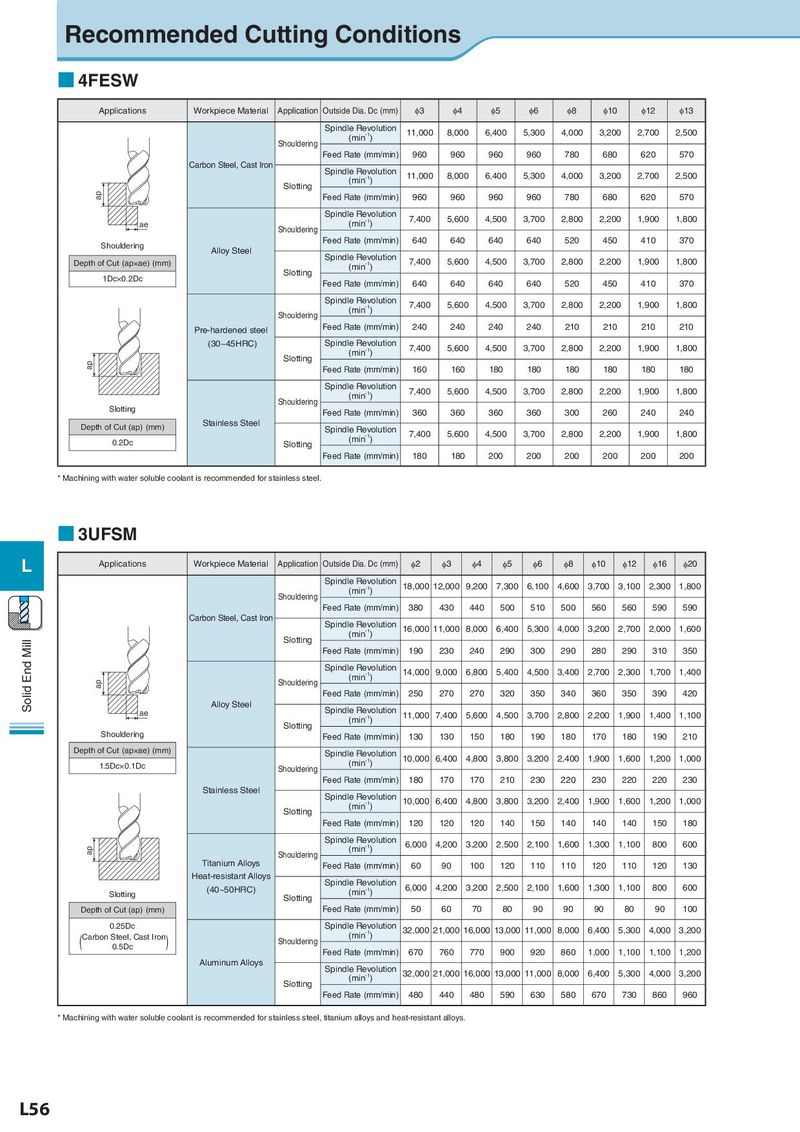

Recommended Cutting Conditions ■ 4FESW Applications Workpiece Material Application Outside Dia. Dc (mm) φ3 φ4 φ5 φ6 φ8 φ10 φ12 φ13 Spindle Revolution 11,000 8,000 6,400 5,300 4,000 3,200 2,700 2,500 Shouldering (min-1) Feed Rate (mm/min) 960 960 960 960 780 680 620 570 Carbon Steel, Cast Iron Spindle Revolution (min-1) 11,000 8,000 6,400 5,300 4,000 3,200 2,700 2,500 Slotting ap Feed Rate (mm/min) 960 960 960 960 780 680 620 570 Spindle Revolution 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,800 ae Shouldering (min-1) Shouldering Feed Rate (mm/min) 640 640 640 640 520 450 410 370 Alloy Steel Spindle Revolution Depth of Cut (ap×ae) (mm) (min-1) 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,800 1Dc×0.2Dc Slotting Feed Rate (mm/min) 640 640 640 640 520 450 410 370 Spindle Revolution 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,800 Shouldering (min-1) Pre-hardened steel Feed Rate (mm/min) 240 240 240 240 210 210 210 210 (30~45HRC) Spindle Revolution 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,800 Slotting (min-1) ap Feed Rate (mm/min) 160 160 180 180 180 180 180 180 Spindle Revolution 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,800 Shouldering (min-1) Slotting Feed Rate (mm/min) 360 360 360 360 300 260 240 240 Depth of Cut (ap) (mm) Stainless Steel Spindle Revolution (min-1) 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,800 0.2Dc Slotting Feed Rate (mm/min) 180 180 200 200 200 200 200 200 * Machining with water soluble coolant is recommended for stainless steel. ■ 3UFSM L Applications Workpiece Material Application Outside Dia. Dc (mm) φ2 φ3 φ4 φ5 φ6 φ8 φ10 φ12 φ16 φ20 Spindle Revolution 18,000 12,000 9,200 7,300 6,100 4,600 3,700 3,100 2,300 1,800 Shouldering (min-1) Feed Rate (mm/min) 380 430 440 500 510 500 560 560 590 590 Carbon Steel, Cast Iron Spindle Revolution (min-1) 16,000 11,000 8,000 6,400 5,300 4,000 3,200 2,700 2,000 1,600 Solid End Mill Slotting Feed Rate (mm/min) 190 230 240 290 300 290 280 290 310 350 Spindle Revolution 14,000 9,000 6,800 5,400 4,500 3,400 2,700 2,300 1,700 1,400 ap Shouldering (min-1) Feed Rate (mm/min) 250 270 270 320 350 340 360 350 390 420 Alloy Steel Spindle Revolution ae (min-1) 11,000 7,400 5,600 4,500 3,700 2,800 2,200 1,900 1,400 1,100 Slotting Shouldering Feed Rate (mm/min) 130 130 150 180 190 180 170 180 190 210 Depth of Cut (ap×ae) (mm) Spindle Revolution 1.5Dc×0.1Dc (min-1) 10,000 6,400 4,800 3,800 3,200 2,400 1,900 1,600 1,200 1,000 Shouldering Feed Rate (mm/min) 180 170 170 210 230 220 230 220 220 230 Stainless Steel Spindle Revolution (min-1) 10,000 6,400 4,800 3,800 3,200 2,400 1,900 1,600 1,200 1,000 Slotting Feed Rate (mm/min) 120 120 120 140 150 140 140 140 150 180 Spindle Revolution 6,000 4,200 3,200 2,500 2,100 1,600 1,300 1,100 800 600 ap Shouldering (min-1) Titanium Alloys Feed Rate (mm/min) 60 90 100 120 110 110 120 110 120 130 Heat-resistant Alloys Spindle Revolution Slotting (40~50HRC) (min-1) 6,000 4,200 3,200 2,500 2,100 1,600 1,300 1,100 800 600 Slotting Depth of Cut (ap) (mm) Feed Rate (mm/min) 50 60 70 80 90 90 90 80 90 100 0.25Dc Spindle Revolution 32,000 21,000 16,000 13,000 11,000 8,000 6,400 5,300 4,000 3,200 ( ) Carbon Steel, Cast Iron Shouldering (min-1) 0.5Dc Feed Rate (mm/min) 670 760 770 900 920 860 1,000 1,100 1,100 1,200 Aluminum Alloys Spindle Revolution (min-1) 32,000 21,000 16,000 13,000 11,000 8,000 6,400 5,300 4,000 3,200 Slotting Feed Rate (mm/min) 480 440 480 590 630 580 670 730 860 960 * Machining with water soluble coolant is recommended for stainless steel, titanium alloys and heat-resistant alloys. L56