Основной каталог Kyocera 2016-2017 - страница 634

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

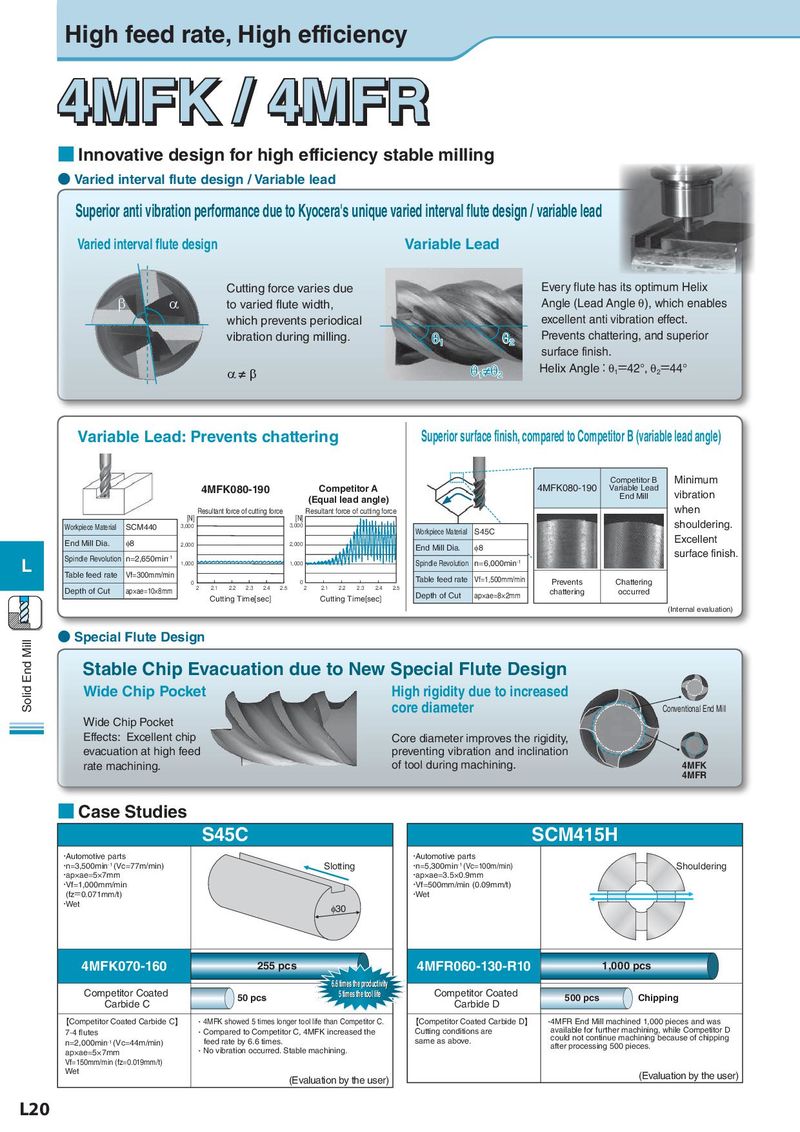

High feed rate, High efficiency 4MFK / 4MFR ■ Innovative design for high efficiency stable milling ● Varied interval flute design / Variable lead Superior anti vibration performance due to Kyocera's unique varied interval flute design / variable lead Varied interval flute design Variable Lead Cutting force varies due Every flute has its optimum Helix β α to varied flute width, Angle (Lead Angle θ), which enables which prevents periodical excellent anti vibration effect. vibration during milling. θ1 θ2 Prevents chattering, and superior surface finish. α≠β θ1≠θ2 Helix Angle:θ1=42°, θ2=44° Variable Lead: Prevents chattering Superior surface finish, compared to Competitor B (variable lead angle) Competitor B Minimum 4MFK080-190 Competitor A 4MFK080-190 Variable Lead vibration (Equal lead angle) End Mill Resultant force of cutting force Resultant force of cutting force when [N] [N] shouldering. Workpiece Material SCM440 3,000 3,000 Workpiece Material S45C Excellent End Mill Dia. φ8 2,000 2,000 End Mill Dia. φ8 Spindle Revolution n=2,650min-1 surface finish. L 1,000 1,000 Spindle Revolution n=6,000min-1 Table feed rate Vf=300mm/min Table feed rate Vf=1,500mm/min Prevents Chattering 0 0 Depth of Cut ap×ae=10×8mm 2 2.1 2.2 2.3 2.4 2.5 2 2.1 2.2 2.3 2.4 2.5 chattering occurred Cutting Time[sec] Cutting Time[sec] Depth of Cut ap×ae=8×2mm (Internal evaluation) Solid End Mill ● Special Flute Design Stable Chip Evacuation due to New Special Flute Design Wide Chip Pocket High rigidity due to increased core diameter Conventional End Mill Wide Chip Pocket Effects: Excellent chip Core diameter improves the rigidity, evacuation at high feed preventing vibration and inclination rate machining. of tool during machining. 4MFK 4MFR ■ Case Studies S45C SCM415H ・Automotive parts ・Automotive parts ・n=3,500min-1 (Vc=77m/min) Slotting ・n=5,300min-1 (Vc=100m/min) Shouldering ・ap×ae=5×7mm ・ap×ae=3.5×0.9mm ・Vf=1,000mm/min ・Vf=500mm/min (0.09mm/t) (fz=0.071mm/t) ・Wet ・Wet φ30 4MFK070-160 255 pcs 4MFR060-130-R10 110,0000pc0s/epdgces 6.6 times the productivity Competitor Coated 50 pcs 5 times the tool life Competitor Coated 500 pcs Chipping Carbide C Carbide D 【Competitor Coated Carbide C】 ・4MFK showed 5 times longer tool life than Competitor C. 【Competitor Coated Carbide D】 ・4MFR End Mill machined 1,000 pieces and was 7·4 flutes ・Compared to Competitor C, 4MFK increased the Cutting conditions are available for further machining, while Competitor D n=2,000min-1 (Vc=44m/min) feed rate by 6.6 times. same as above. could not continue machining because of chipping ap×ae=5×7mm ・No vibration occurred. Stable machining. after processing 500 pieces. Vf=150mm/min (fz=0.019mm/t) Wet (Evaluation by the user) (Evaluation by the user) L20