Основной каталог Kyocera 2016-2017 - страница 632

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

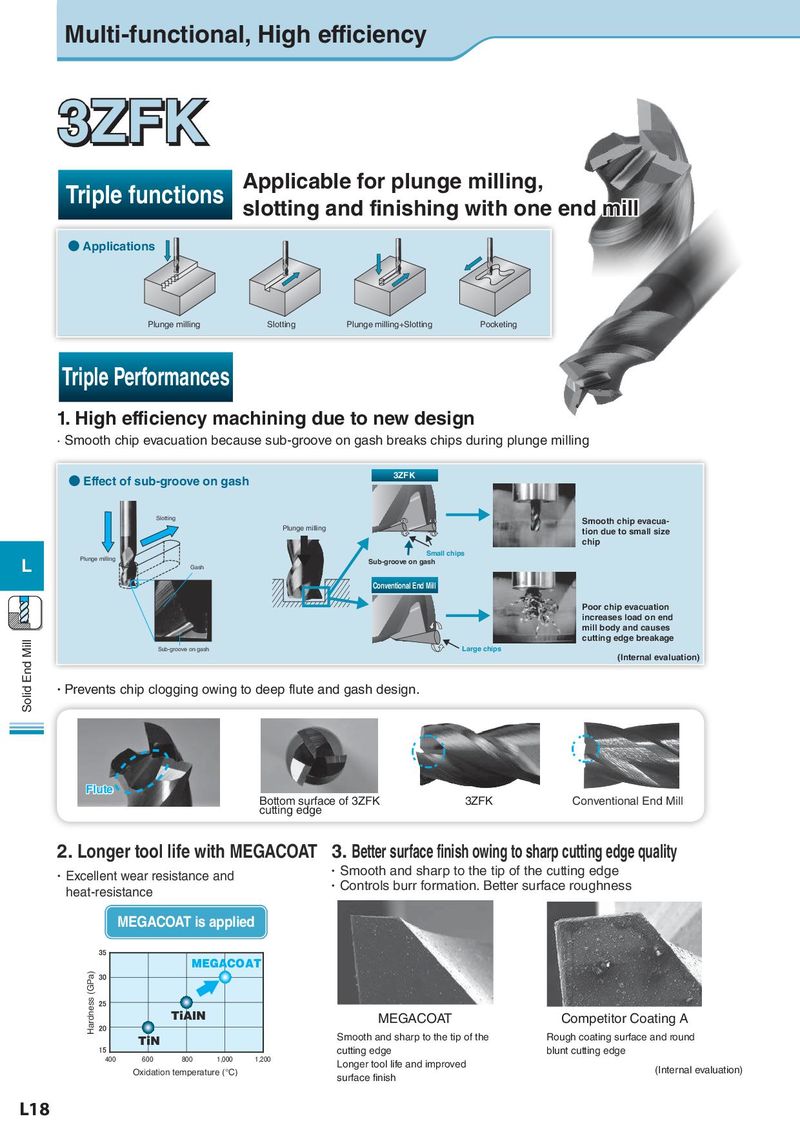

Multi-functional, High efficiency 3ZFK Triple functions Applicable for plunge milling, slotting and finishing with one end mill ● Applications Plunge milling Slotting Plunge milling+Slotting Pocketing Triple Performances 1. High efficiency machining due to new design · Smooth chip evacuation because sub-groove on gash breaks chips during plunge milling ● Effect of sub-groove on gash 3ZFK Slotting Smooth chip evacua- Plunge milling tion due to small size chip Plunge milling Small chips L Sub-groove on gash Gash Conventional End Mill Poor chip evacuation increases load on end mill body and causes Solid End Mill cutting edge breakage Sub-groove on gash Large chips (Internal evaluation) ・Prevents chip clogging owing to deep flute and gash design. Flute Bottom surface of 3ZFK 3ZFK Conventional End Mill cutting edge 2. Longer tool life with MEGACOAT 3. Better surface finish owing to sharp cutting edge quality ・Excellent wear resistance and ・Smooth and sharp to the tip of the cutting edge heat-resistance ・Controls burr formation. Better surface roughness MEGACOAT is applied MEGACOAT Hardness (GPa) TiAlN MEGACOAT Competitor Coating A TiN Smooth and sharp to the tip of the Rough coating surface and round cutting edge blunt cutting edge 400 600 800 1,000 1,200 Longer tool life and improved Oxidation temperature (°C) surface finish (Internal evaluation) L18