Основной каталог Kyocera 2016-2017 - страница 606

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

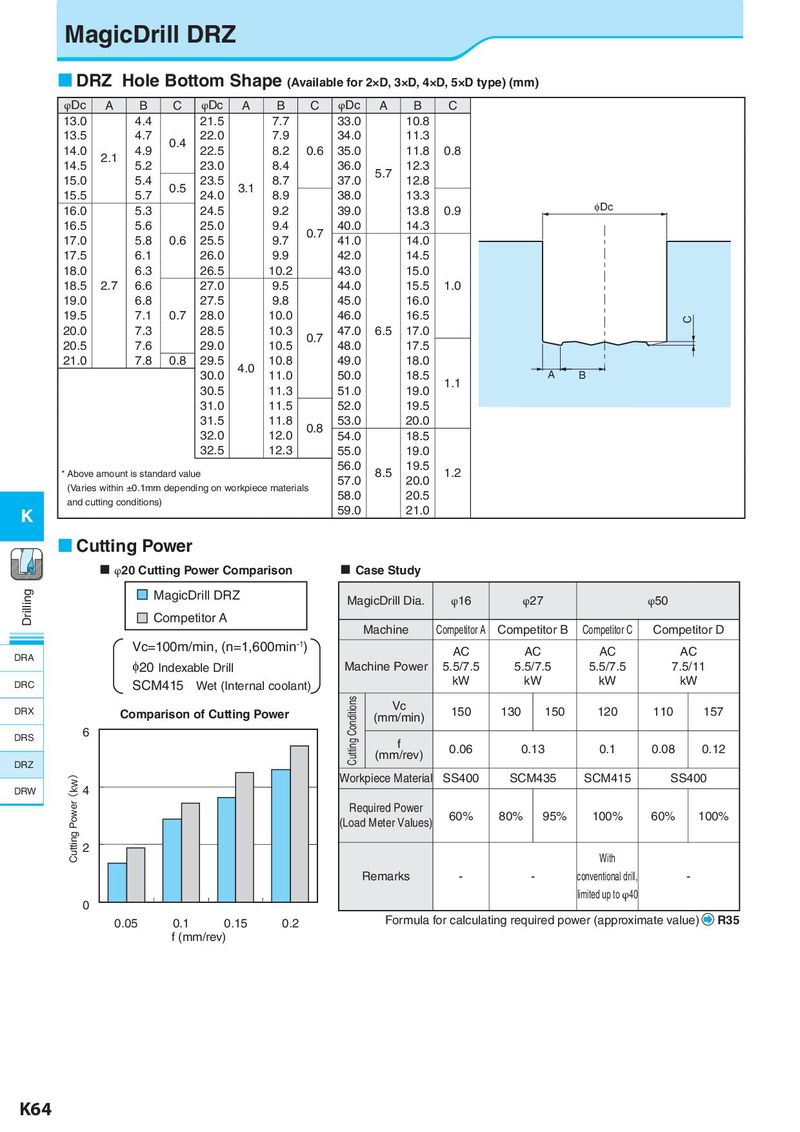

MagicDrill DRZ DRZ Hole Bottom Shape (Available for 2×D, 3×D, 4×D, 5×D type) (mm) φDc A B C φDc A B C φDc A B C 13.0 4.4 21.5 7.7 33.0 10.8 13.5 4.7 0.4 22.0 7.9 34.0 11.3 14.0 2.1 4.9 22.5 8.2 0.6 35.0 11.8 0.8 14.5 5.2 23.0 8.4 36.0 5.7 12.3 15.0 5.4 0.5 23.5 3.1 8.7 37.0 12.8 15.5 5.7 24.0 8.9 38.0 13.3 16.0 5.3 24.5 9.2 39.0 13.8 0.9 IDc 16.5 5.6 25.0 9.4 0.7 40.0 14.3 17.0 5.8 0.6 25.5 9.7 41.0 14.0 17.5 6.1 26.0 9.9 42.0 14.5 18.0 6.3 26.5 10.2 43.0 15.0 18.5 2.7 6.6 27.0 9.5 44.0 15.5 1.0 19.0 6.8 27.5 9.8 45.0 16.0 19.5 7.1 0.7 28.0 10.0 46.0 16.5 C 20.0 7.3 28.5 10.3 0.7 47.0 6.5 17.0 20.5 7.6 29.0 10.5 48.0 17.5 21.0 7.8 0.8 29.5 4.0 10.8 49.0 18.0 30.0 11.0 50.0 18.5 1.1 A B 30.5 11.3 51.0 19.0 31.0 11.5 52.0 19.5 31.5 11.8 0.8 53.0 20.0 32.0 12.0 54.0 18.5 32.5 12.3 55.0 19.0 * Above amount is standard value 56.0 8.5 19.5 1.2 (Varies within ±0.1mm depending on workpiece materials 57.0 20.0 and cutting conditions) 58.0 20.5 K 59.0 21.0 Cutting Power φ20 Cutting Power Comparison Case Study Drilling MagicDrill DRZ MagicDrill Dia. φ16 φ27 φ50 Competitor A Machine Competitor A Competitor B Competitor C Competitor D Vc=100m/min, (n=1,600min-1) AC AC AC AC DRA I20 Indexable Drill Machine Power 5.5/7.5 5.5/7.5 5.5/7.5 7.5/11 DRC SCM415 Wet (Internal coolant) kW kW kW kW DRX Comparison of Cutting Power Cutting Conditions Vc 150 130 150 120 110 157 (mm/min) DRS 6 f 0.06 0.13 0.1 0.08 0.12 DRZ (mm/rev) kw ︶ Workpiece Material SS400 SCM435 SCM415 SS400 DRW 4 Cutting Power︵ Required Power (Load Meter Values) 60% 80% 95% 100% 60% 100% 2 With Remarks - - conventional drill, - 0 limited up to φ40 0.05 0.1 0.15 0.2 Formula for calculating required power (approximate value) R35 f (mm/rev) K64