Основной каталог Kyocera 2016-2017 - страница 579

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

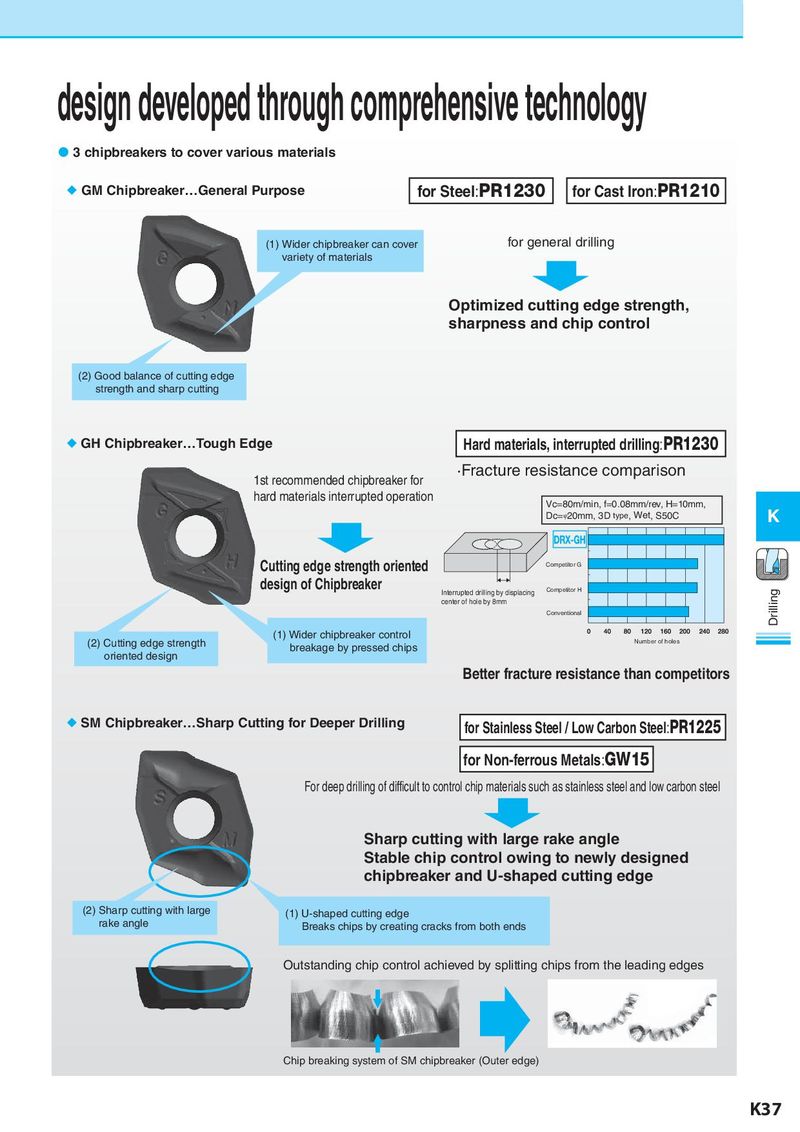

design developed through comprehensive technology 3 chipbreakers to cover various materials GM Chipbreaker…General Purpose for Steel:PR1230 for Cast Iron:PR1210 (1) Wider chipbreaker can cover for general drilling variety of materials Optimized cutting edge strength, sharpness and chip control (2) Good balance of cutting edge strength and sharp cutting GH Chipbreaker…Tough Edge Hard materials, interrupted drilling:PR1230 1st recommended chipbreaker for ·Fracture resistance comparison hard materials interrupted operation Vc=80m/min, f=0.08mm/rev, H=10mm, Dc=φ20mm, 3D type, Wet, S50C K Cutting edge strength oriented Competitor G design of Chipbreaker Interrupted drilling by displacing Competitor H Drilling center of hole by 8mm Conventional (2) Cutting edge strength (1) Wider chipbreaker control Number of holes oriented design breakage by pressed chips Better fracture resistance than competitors SM Chipbreaker…Sharp Cutting for Deeper Drilling for Stainless Steel / Low Carbon Steel:PR1225 for Non-ferrous Metals:GW15 For deep drilling of difficult to control chip materials such as stainless steel and low carbon steel Sharp cutting with large rake angle Stable chip control owing to newly designed chipbreaker and U-shaped cutting edge (2) Sharp cutting with large (1) U-shaped cutting edge rake angle Breaks chips by creating cracks from both ends Outstanding chip control achieved by splitting chips from the leading edges Chip breaking system of SM chipbreaker (Outer edge) K37