Основной каталог Kyocera 2016-2017 - страница 55

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

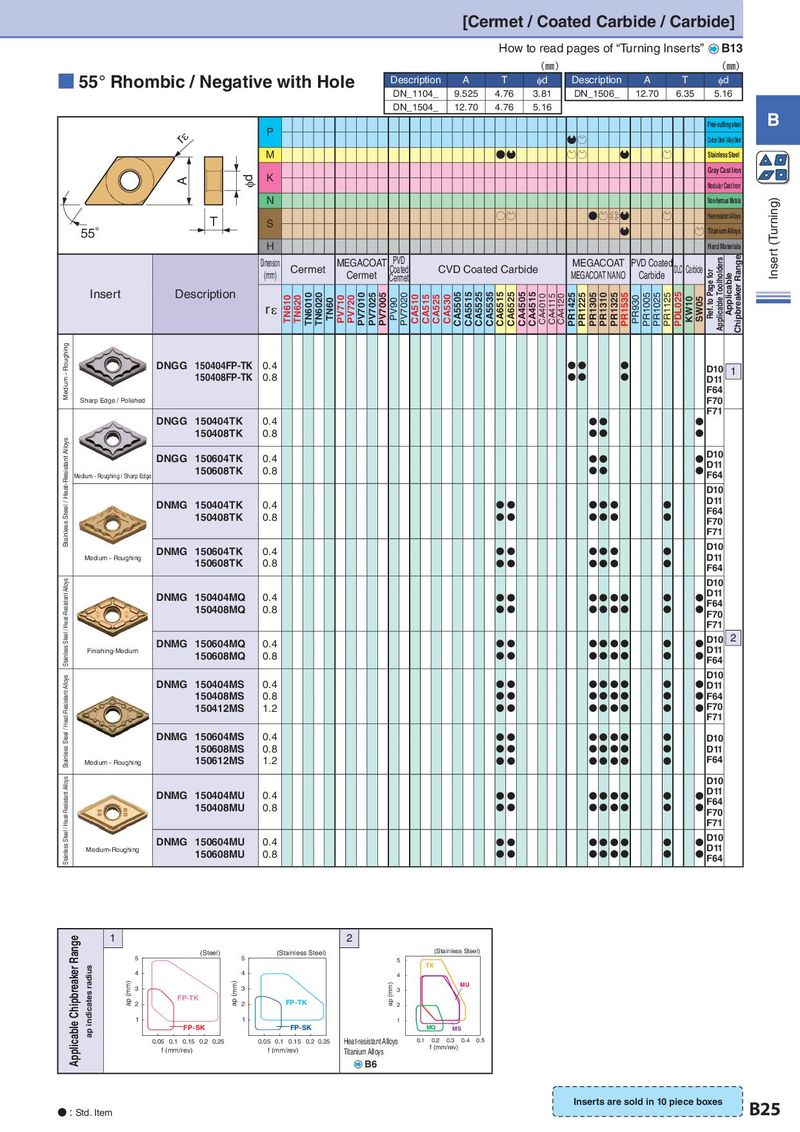

[Cermet / Coated Carbide / Carbide] How to read pages of “Turning Inserts” B13 (㎜) (㎜) ■ 55° Rhombic / Negative with Hole Description A T φd Description A T φd DN_1104_ 9.525 4.76 3.81 DN_1506_ 12.70 6.35 5.16 DN_1504_ 12.70 4.76 5.16 P Free-cutting steel B rH QP Carbon Steel / Al oy Steel M NQ PP Q P Stainless Steel Id K Gray Cast Iron A Nodular Cast Iron N Non-ferrous Metals (Turning) T S OP NPSQ P Heat-resistant Alloys 55° Q P Titanium Alloys H Hard Materials Inser t Dimension MEGACOAT PVD MEGACOAT PVD Coated Applicable Toolholders Chipbreaker Range Cermet Coated CVD Coated Carbide DLC Carbide (mm) Cermet Cermet MEGACOAT NANO Carbide Ref. to Page for Applicable Insert Description TN610 TN620 TN6010 TN6020 TN60 PV710 PV720 PV7010 PV7025 PV7005 PV90 PV7020 CA510 CA515 CA525 CA530 CA5505 CA5515 CA5525 CA5535 CA6515 CA6525 CA4505 CA4515 CA4010 CA4115 CA4120 PR1425 PR1225 PR1305 PR1310 PR1325 PR1535 PR930 PR1005 PR1025 PR1125 PDL025 KW10 SW05 rε Medium - Roughing DNGG 150404FP-TK 0.4 NN N D10 1 150408FP-TK 0.8 NN N D11 F64 Sharp Edge / Polished F70 N N N F71 DNGG 150404TK 0.4 Stainless Steel / Heat-Resistant Alloys 150408TK 0.8 N N N DNGG 150604TK 0.4 N N N D10 150608TK 0.8 N N N D11 Medium - Roughing / Sharp Edge F64 D10 D11 DNMG 150404TK 0.4 NN N N N N F64 150408TK 0.8 N N N N N N F70 F71 DNMG 150604TK 0.4 N N N N N N D10 Medium - Roughing 150608TK 0.8 N N N N N N D11 F64 Stainless Steel / Heat-Resistant Alloys D10 DNMG 150404MQ 0.4 NN N N N N N N D11 150408MQ 0.8 N N N N N N N N F64 F70 F71 DNMG 150604MQ 0.4 N N N N N N N N D10 2 Finishing-Medium 150608MQ 0.8 N N N N N N N N D11 F64 Stainless Steel / Heat-Resistant Alloys D10 DNMG 150404MS 0.4 N N NNNN N N D11 150408MS 0.8 N N N N N N N N F64 150412MS 1.2 N N N N N N N N F70 F71 DNMG 150604MS 0.4 N N N N N N N D10 150608MS 0.8 N N N N N N N D11 Medium - Roughing 150612MS 1.2 N N N N N N N F64 Stainless Steel / Heat-Resistant Alloys D10 DNMG 150404MU 0.4 N N N N N N N N D11 150408MU 0.8 N N N N N N N N F64 F70 F71 DNMG 150604MU 0.4 N N N N N N N N D10 Medium-Roughing 150608MU 0.8 N N N N N N N N D11 F64 Applicable Chipbreaker Range 1 2 (mm) (mm) (Steel) (mm) (Stainless Steel) (Stainless Steel) 5 5 5 ap indicates radius TK 4 4 4 ap (mm) 3 ap (mm) 3 ap (mm) MU 3 2 FP-TK 2 FP-TK 2 1 1 1 FP-SK FP-SK MQ MS 0.05 0.1 0.15 0.2 0.25 0.05 0.1 0.15 0.2 0.25 Heat-resistant Alloys 0.1 0.2 0.3 0.4 0.5 f (mm/rev) f (mm/rev) Titanium Alloys f (mm/rev) B6 Inserts are sold in 10 piece boxes B25 ● : Std. Item