Основной каталог Kyocera 2016-2017 - страница 522

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

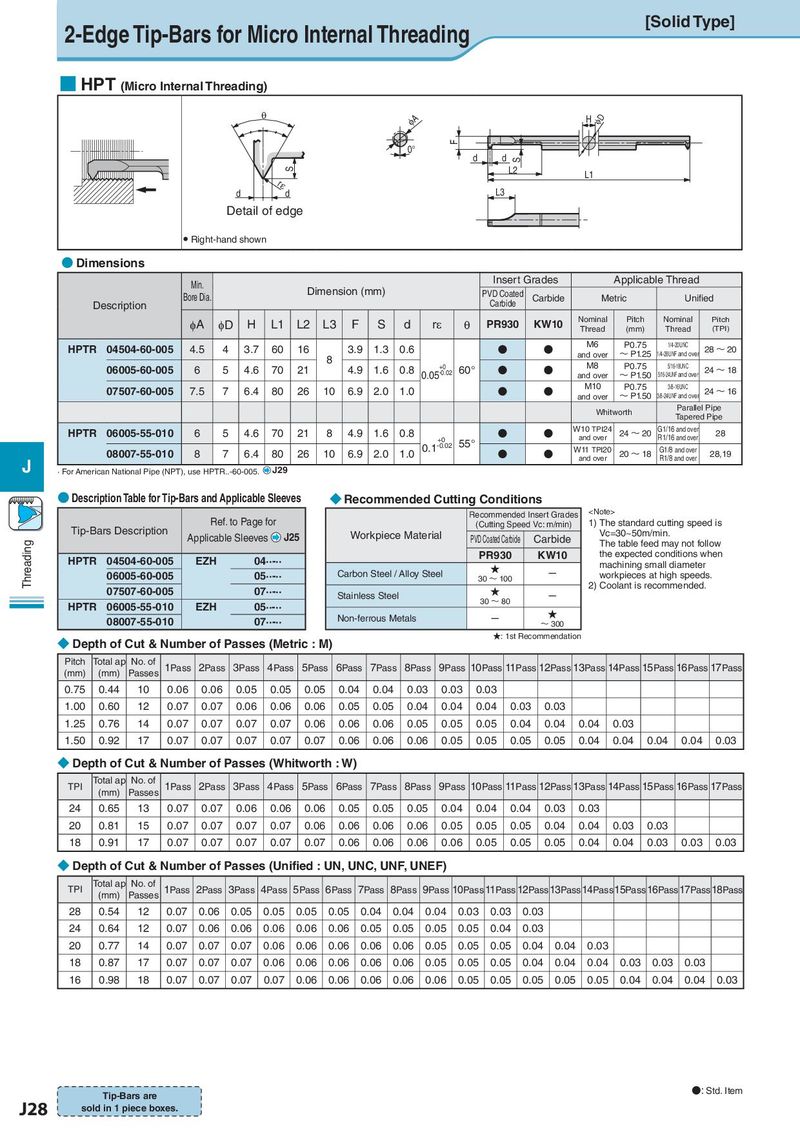

2-Edge Tip-Bars for Micro Internal Threading [Solid Type]

■ HPT (Micro Internal Threading)

T IA H ID

F

0° d d

S

S L2 L1

rH L3

d d

Detail of edge

● Right-hand shown

● Dimensions

Min. Insert Grades Applicable Thread

Bore Dia. Dimension (mm) PVD Coated Carbide Metric Unified

Description Carbide

φA φD H L1 L2 L3 F S d rε θ PR930 KW10 Nominal Pitch Nominal Pitch

Thread (mm) Thread (TPI)

HPTR 04504-60-005 4.5 4 3.7 60 16 3.9 1.3 0.6 N N M6 P0.75 1/4-20UNC 28 ~ 20

8 and over ~ P1.25 1/4-28UNF and over

06005-60-005 6 5 4.6 70 21 4.9 1.6 0.8 +0 60° N N M8 P0.75 5/16-18UNC 24 ~ 18

0.05-0.02 and over ~ P1.50 5/16-24UNF and over

07507-60-005 7.5 7 6.4 80 26 10 6.9 2.0 1.0 N N M10 P0.75 3/8-16UNC 24 ~ 16

and over ~ P1.50 3/8-24UNF and over

Whitworth Parallel Pipe

Tapered Pipe

HPTR 06005-55-010 6 5 4.6 70 21 8 4.9 1.6 0.8 N N W10 TPI24 24 ~ 20 G1/16 and over 28

+0 55° and over R1/16 and over

08007-55-010 8 7 6.4 80 26 10 6.9 2.0 1.0 0.1-0.02 N N W11 TPI20 20 ~ 18 G1/8 and over 28,19

J and over R1/8 and over

· For American National Pipe (NPT), use HPTR..-60-005. J29

● Description Table for Tip-Bars and Applicable Sleeves ◆ Recommended Cutting Conditions

Recommended Insert Grades