Основной каталог Kyocera 2016-2017 - страница 515

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

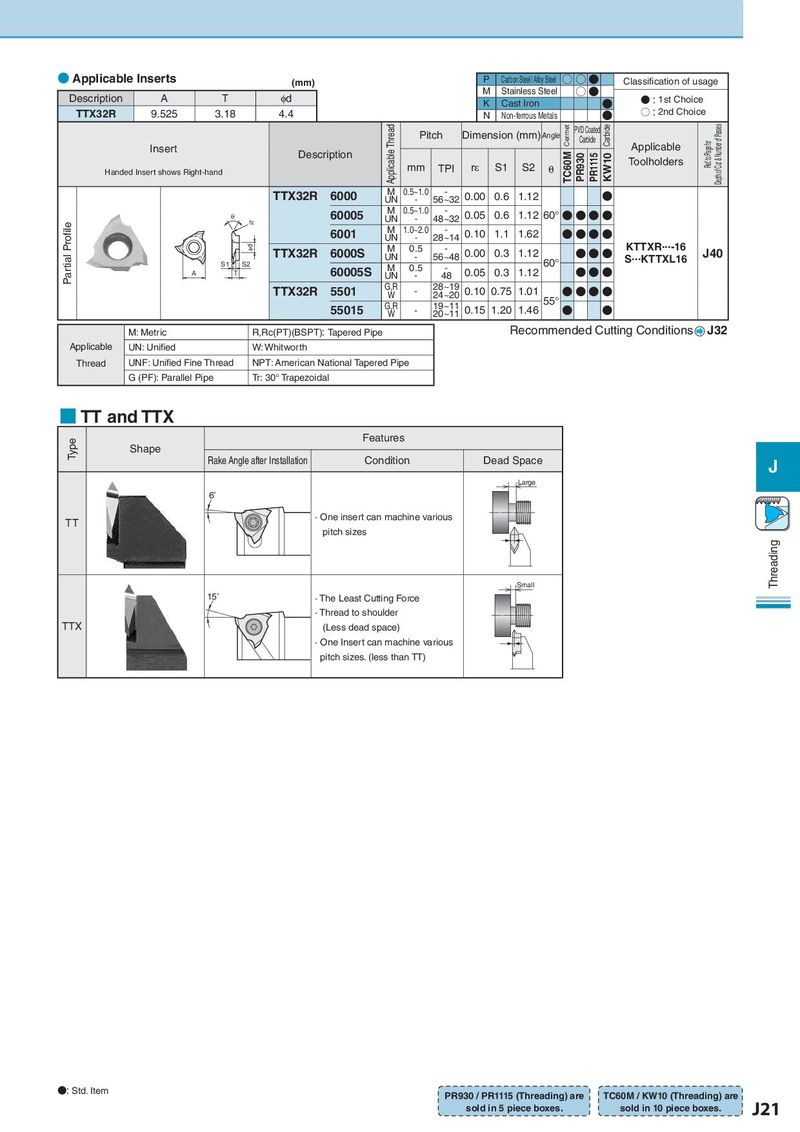

● Applicable Inserts (mm) P Carbon Steel / Alloy Steel ○○ ● Classification of usage Description A T φd M Stainless Steel ○ ● ● : 1st Choice K Cast Iron ● ○ : 2nd Choice TTX32R 9.525 3.18 4.4 N Non-ferrous Metals ● Applicable Thread Pitch Dimension (mm)Angle Cermet PVD Coated Carbide Depth of Cut & Number of Passes Carbide Applicable Ref.to Page for Insert Description TC60M PR930 PR1115 KW10 mm TPI rε S1 S2 θ Toolholders Handed Insert shows Right-hand TTX32R 6000 M 0.5~1.0 - 0.00 0.6 1.12 ● UN - 56~32 T 60005 M 0.5~1.0 - 0.05 0.6 1.12 60° ● ● ● ● UN - 48~32 Profile rH 6001 M 1.0~2.0 - 0.10 1.1 1.62 ●●●● UN - 28~14 KTTXR...-16 Id TTX32R 6000S M 0.5 - 0.00 0.3 1.12 ●●● J40 Partial S1 S2 UN - 56~48 60° S...KTTXL16 A T 60005S M 0.5 - 0.05 0.3 1.12 ●●● UN - 48 TTX32R 5501 G,R - 28~19 0.10 0.75 1.01 ●●●● W 24~20 55° 55015 G,R 19~11 0.15 1.20 1.46 ● ● W - 20~11 M: Metric R,Rc(PT)(BSPT): Tapered Pipe Recommended Cutting Conditions J32 Applicable UN: Unified W: Whitworth Thread UNF: Unified Fine Thread NPT: American National Tapered Pipe G (PF): Parallel Pipe Tr: 30° Trapezoidal ■ TT and TTX Type Features Shape Rake Angle after Installation Condition Dead Space J Large 6° TT · One insert can machine various pitch sizes Small Threading 15° · The Least Cutting Force · Thread to shoulder TTX (Less dead space) · One Insert can machine various pitch sizes. (less than TT) ●: Std. Item PR930 / PR1115 (Threading) are TC60M / KW10 (Threading) are sold in 5 piece boxes. sold in 10 piece boxes. J21